1. Features of the Design

Steam jacketed globe valves are made with a variety of factors taken into account to satisfy the various pipeline control needs in various industrial sectors:

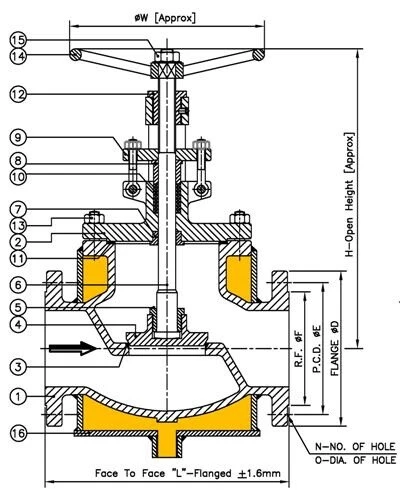

1)Closure Mechanism Design: When the valve is closed, complete sealing is ensured by the use of tapered valve plugs with sealing surfaces that might be conical or flat. This effectively stops media leakage.

2)There are two types of valve stem movement: rotating stem movement and rising and lowering stem movement. Operator control of the valve is made easier by the rising and lowering stem's design, which isolates the stem's movement from the handwheel's function.

3)Features: They are appropriate for fully open and fully closed positions, but not for throttling or adjusting, guaranteeing the stability and dependability of the valve.

4)Material Selection: To provide long-term stable operation under challenging conditions, valve materials typically comprise of corrosion- and high-temperature-resistant alloy alloys.

2. Advantages and Disadvantages

Like any engineering solution, steam jacketed globe valves offer Advantages and Disadvantages of their own.

Major Advantages

1)Excellent Sealing: To provide a long service life and efficiently prevent media leakage, use tapered valve plugs with little friction between sealing surfaces.

2)Easy to Use: Steam jacketed globe valves are ideal for circumstances needing quick reaction because of their straightforward design and quick opening and shutting speeds.

3)High Reliability: Steam jacketed globe valves exhibit steady performance and low failure rates over an extended period of use thanks to meticulous design and testing.

Some Disadvantages

1)High Fluid Resistance: Steam jacketed globe valves create a lot of fluid resistance when they open and close because of their structural features, which makes them harder to operate.

2)Media Restrictions: Their use is limited in some situations by their incompatibility with media that include particles, have a high viscosity, or have a tendency to coke.

3)Inadequate Adjustment Performance: Steam jacketed globe valves are less effective at adjusting than other valve types, making them unsuitable for applications needing exact flow control.

3. Applications

Steam jacketed globe valves are widely used in many different industries, however they are most commonly found in the following:

1)Transportation of High-Viscosity Media: Steam jacketed globe valves efficiently regulate media flow, guaranteeing the regular operation of systems, for high-viscosity media that are prone to solidification at standard temperatures, such as petroleum and asphalt.

2)Chemical and Fertilizer Industries: It's critical to avoid crystallization problems impacting system performance in these industries because of the special qualities of the media used in these sectors. Steam jacketed globe valves are hence frequently employed. Continuous system operation is ensured by injecting steam into the jacket to prevent media crystallization.

3)Pharmaceutical Industry: Steam jacketed globe valves provide the stability and purity of the media in pharmaceutical production, where strict control over the medium is required. This helps to maintain the quality of pharmaceutical goods.

In industrial pipeline systems, steam jacketed globe valves are essential parts that provide steady operation and security. Although their use and design satisfy industry demands, they are not without difficulties. Steam jacketed globe valves will continue to grow in response to changing demands and technical breakthroughs, offering more dependable and effective industrial pipeline control systems.