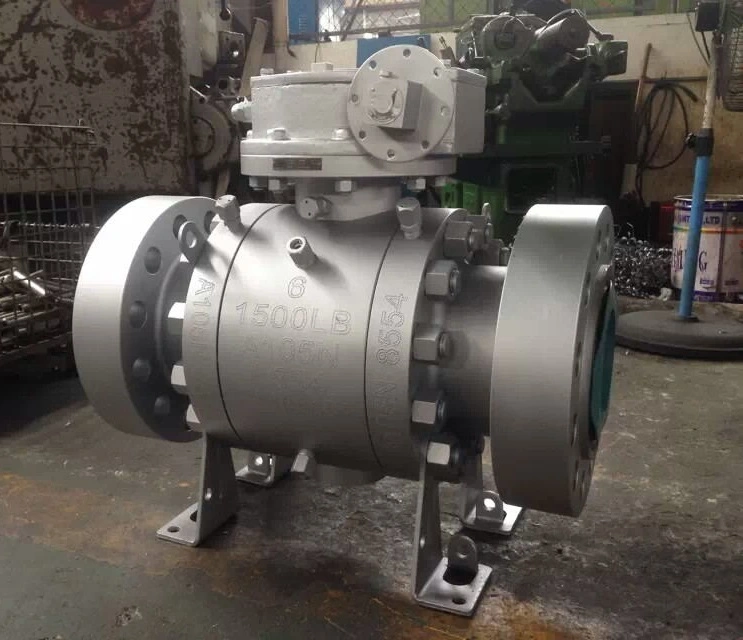

The trim of forged steel ball valve is carefully selected, and valve body thickness and bolt strength are in accordance with the requirements of the American standard ASME B16.34, which are strictly calculated to ensure the corresponding class rating and reliable strength of joint.

The ball valve has trunnion mounted ball and floating seat, which generate small torque under operating pressure. A metal bushing with self-lubricating PTFE is used to cooperate with high-strength and high-gloss valve stem to minimize the friction coefficient.

The forged steel ball valve uses polymer as valve seal material, and its seat is spring-loaded, which give it excellent sealing performance over a wide range of temperature changes and pressure variations, and ensures a bubble-free seal under the closed pressure difference. Even at the maximum differential pressure, the operating torque can be the minimum.

The forged steel ball valves meet the requirements of specifications and pressure ratings according to American Petroleum Institute API 6D/ISO 14314 and ASME standards.Upon customer's requirement, material in accordance with the American Society of Corrosion Engineers NACE MR 0175 or NACE MR 0103 can be used.

The design and quality system of the ball valve is based on the ISO 9001 quality system standard and API Q1 quality outline specification. It is approved by DNV Classification Society and API Petroleum Institute, and conforms to ISO 9001 quality system standard and API Q1 and API 6D specification.