What is a Gate Valve?

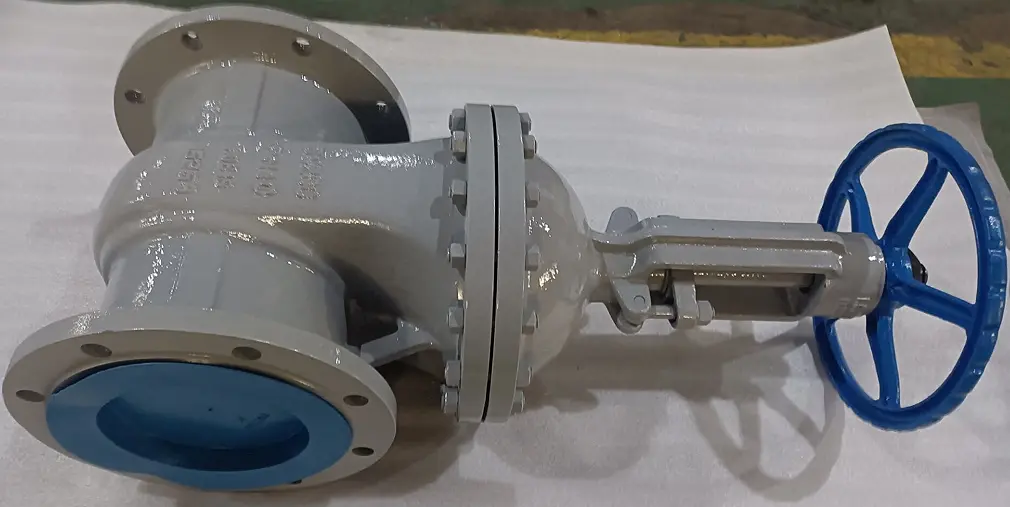

Often referred to as sluice valves, a gate valve purchased from reputable China valves manufacturers is used in historic homes to give the occupants control over the flow rate of the medium. It does not provide a sudden stop, but it does feature gradual trickles rather than a continuous flow. Their mechanism is a spherical knob that, when rotated, lowers and raises the internal gate, or wedge, controlling the rate at which water flows.In water delivery systems, a gate valve is the most common type. It is not the best idea to control the flow with this liner-motion isolation device. Rather, it opens or closes the flow fully because a partial opening is harmful. It isolates specific areas of a water supply network so that repairs, new installations, maintenance, and flow rerouting can be done.

These gadgets come in a range of shapes, sizes, compositions, pressure levels, and temperatures. Actuator gate valves are also available in electric and pneumatic varieties for a variety of uses. Due to its versatile applicability and straightforward design, this valve is widely utilized in low-pressure drop scenarios.

Gate valves usually have a full-port design that permits fluid to pass through without hindrance and results in a pipeline pressure reduction. It makes it possible to clean the channels using a cleaning pig as a result.

What is a Shut-Off Valve?

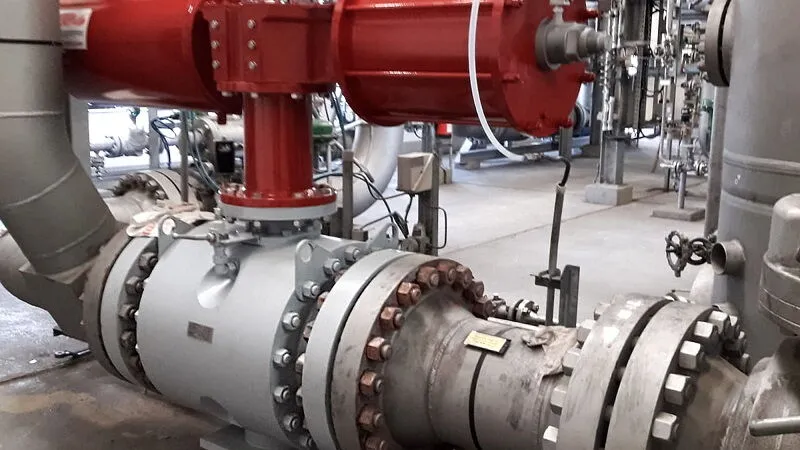

Shut-off valves, also referred to as ball valves, are commonly used in contemporary homes to regulate the medium's flow. As the name implies, a shut-off valve stops medium flow from one opening to the next by means of a rotatory ball with a bore.

It uses a handle to track where a perforated, hollow spherical is positioned within the mechanism. The hole opens or closes the water flow in tandem with the handle's rotation. The location of the handle makes it simple to tell if the valve is open or closed. The handle rests flat and in line with the flow when it is accessible. The handle is perpendicular to the flow once it is finished.

For gaseous applications, a shut-off valve is the optimum option because to its robust seal, durability, and safe and dependable closure even after extended periods of inactivity. Even after multiple cycles, the equipment of an industrial valves company remains functional. Compared to most other valve types, they are more resistant to polluted media, therefore even under dirty media conditions, they maintain a good seal.

The ball valve can be used in a pipeline for control and shut-off applications because of all these features.

Shut Off Valve vs Gate Valve

As one of the most important components of a plumbing system, valves must perform properly to prevent leaks and undesired flow. Shut-off and gate valves are the most common types of valves accessible today, while there are other varieties as well. To choose the right gate valve or shut off valve for a certain application, it is essential to understand the differences between the two.

| BASIS OF DIFFERENCE | SHUT OFF VALVE | GATE VALVE |

| SHUT OFF MECHANISM | It provides fast shut-off, requiring just a quarter turn, or 90 degrees, to seal the gadget. | With about a full 360-degree rotation needed to shut off, it provides a delayed shut-off. |

| WATER HAMMER | A water hammer could result from the valve opening and closing quickly. | Water hammer is less likely when the valve is opened and closed slowly. |

| VISUAL DETECTION | The handle position makes it simple to determine if a state is open or closed. | The handle position may not always indicate whether a form is closed or loose. |

| COST | more costly than a gate valve with equivalent specs. | less expensive than a shut-off valve with comparable specs. |

| INSTALLATION SPACE | More room is needed in order to fit a quarter-turn handle. | less installation area is needed than with a shut-off valve. |

| SIZE | Suitable for bore sizes below two inches. | Ideal for bore sizes above two inches. |

| LEAKAGE | It maintains its tight sealing even after extended use. | more likely than a shut-off valve to leak. |

| DURABILITY | Robust and less prone to breaking. | less stable due to the corrosive nature of the valve stem. |

| APPLICATIONS | Marine applications and fire prevention systems. | Power plants, mining, and Water Treatment. |

| ENVIRONMENT | Low-temperature and low-pressure environments. | High-temperature and high-pressure environments. |

| MAINTENANCE | challenging to clean since the slurry particles could contaminate and harm the rotatory ball. | Ideal for applications involving slurries and viscous media due to their ease of cleaning and upkeep. |

| SUITABILITY | Ideal for recently installed plumbing systems that need to shut down often. | Perfect for uses where frequent shut-offs are not necessary. |

| OTHER NAMES | Industrial ball valves | Multi-turn or Sluice valve |

How to Choose Between a Gate Valve and a Shut-Off Valve?

The following list of factors should be taken into account when choosing between a gate and a ball valve:

- Number of Ports: A shut-off valve has more than two ports, whereas a gate valve only has two.

- The Flow capacity: Due to its bigger dimensions, a gate valve has a higher flow capacity than a shut-off valve.

- Pressure:A gate valve is a better option for high-pressure applications since the rapid opening and closing of a ball valve can result in a water hammer. Both, though, are ideal for low-pressure uses.

- Cost: Generally speaking, a ball valve costs more than a gate valve from a manufacturer with comparable specs.

- Maintenance: A ball valve is a better option than a gate valve if the application calls for less maintenance. So, in the long term, it is more cost-effective.

- Sealing: Compared to a gate valve, a shut-off valve provides complete closure and tight sealing. It is therefore more appropriate for uses using natural gas.

- Shut-off Speed: Applications needing a quicker opening and shutting speed, particularly in an emergency, are suited for shut-off valves. However, an industrial gate valve operates more slowly than a ball valve because it requires more than 360 degrees of rotation.

Parting Thoughts

A rotatory ball with a bore and a stem make up a ball valve. The ball rotates to open or close the flow in tandem with the handle on a stem. Because it requires a quarter turn (90 degrees) of its grip to allow or prohibit media flow, it is often referred to as a quarter-turn valve.

A gate is included in a gate valve to regulate the media flow via the pipe. It is attached to the stem by a solid disk structure. To open the valve, the gate raises, and to close it, it lowers back to its starting position. It has a bonnet to regulate the gate's rotation.

Use of a gate or shut-off valve can be determined based on the application. Please get in touch with us to get these long-lasting devices at prices that are usually lower than those found on the market.