Two of the most popular plumbing choices are ball and angle valves, each of which has advantages and disadvantages. Even though either have their advantages and disadvantages, it's critical to comprehend them both so that individuals can select the option that best meets their individual requirements. This is all the information about JONLOO valves that one needs to know in order to decide wisely before investing in one for a project or company.

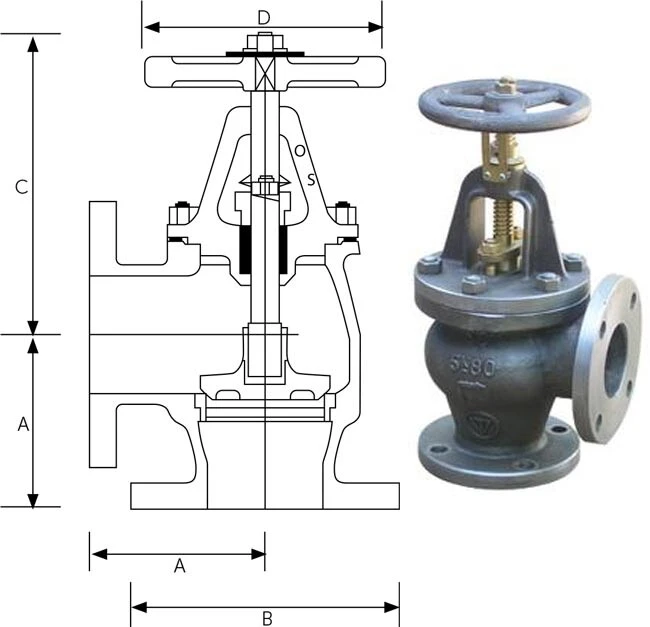

An angle valve is a tool for controlling the flow of gas or liquid via a pipeline. Angle valves are commonly employed in plumbing applications, both residential and commercial, to control the flow of water inside a system. Chemical processing facilities and other industrial settings are among the uses for angle valves.

Liquid and gas flow can be managed with the use of an angle valve. It gets its name from its triangular shape, which makes it able to squeeze into confined areas. Angle valves are frequently utilized in industrial and plumbing settings. The angle valve functions by allowing or prohibiting the passage of liquid or gas via an aperture with a triangle form. The liquid or gas flow can be managed by adjusting the opening size.

Two of the three ports on the angle valve can be opened and closed. To ensure continuous pressure, the third port will remain open at all times. Angle valves are available in smaller sizes than ball valves and are mostly utilized for the transfer of liquids.

Angle valves provide easy flow rate regulation for those who wish to completely stop or modify the flow rate. Additionally, they work better in applications where quick variations in flow rate are necessary (like hot water). Because of its 90° orientation during installation, angle valves take up more room than ball valves; therefore, if space is at a premium, choose a ball valve.

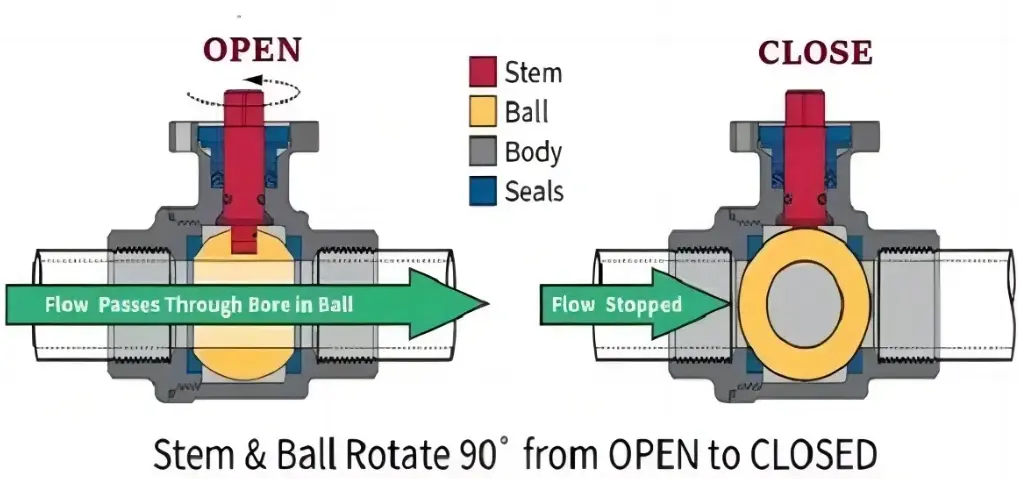

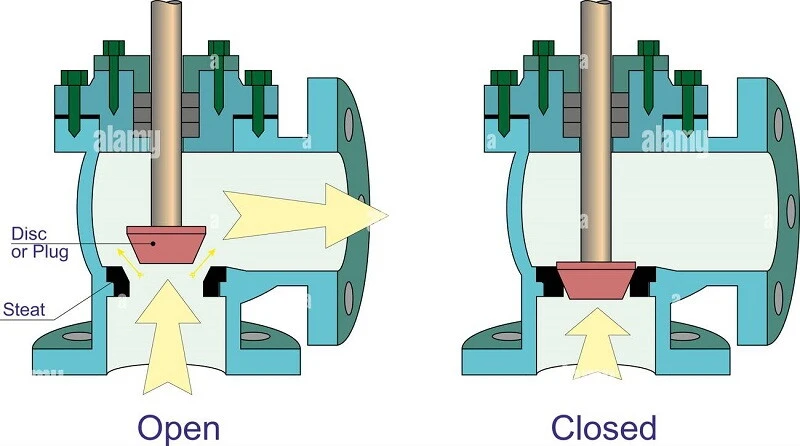

A ball valve regulates the flow of fluid through it using a spherical disk. A rod that passes through the valve's center holds the disk in place. Fluid can pass through when the valve is opened because the disk rotates to be perpendicular to the opening. The disk rotates to parallel the opening when the valve is closed, preventing fluid passage. Oil pipelines, chemical processing facilities, and water and gas lines are just a few of the places where ball valves are employed.

One side of a ball valve has a handle that resembles a wheel. The disc inside the valve rotates in response to handle rotation, opening or closing the valve's opposite side opening. A ball valve restricts the amount of water that can flow through it by making the aperture smaller, allowing for the passage of less water through at once. Ball valves are most commonly used by connecting them to garden hoses and controlling the flow from there. When connected, the nozzle will release more water the higher we move it from its resting position (and vice versa).

Here are a few differences:

Here are a few differences:

- If someone makes a lot of left-hand turns, a ball valve is preferable to an angle valve. The abrupt bend may raise the likelihood of sticking by creating more friction. On the other hand, if the water lines are in front of something that is prone to breaking, an angle valve might be the best option. A refrigerator or gas fireplace would be examples of such possible damage points. Since the valves are behind a wall and out of reach of anything, they are safe.

- Ball valves need more upkeep than angle valves, but if the installation site allows for easy access to the entire plumbing system, this might not be an issue.

- An angle valve can be used with PEX or copper tubing. Only metal pipe connectors (copper, steel, or PVC) can be used with a ball valve. When using a ball valve to close off a line, remove the handle from the threaded shaft of the valve. After that, rotate it 180 degrees to shut off the fitting's flow and seal it against the flange plate's inner wall.

- Whichever type you select, make sure it fits snugly. A ball valve should slide smoothly into the piping nipple's aperture and protrude a little past the threads, whereas an angled valve should sit squarely over it. Even when completely tightened, neither should ever leak; nonetheless, take care not to overtighten. Replace any bolts that are excessively loose before moving on to the next step.

Because they seat flush to the pipe, angle valves usually don't require gaskets, but if necessary, you can use them (they should last 20 years or more). Installing angle valves is generally simpler than installing ball valves for most people. Take care not to install a valve in the incorrect way! - Unlike a ball valve, which has sharp edges, an angle valve's outlet has a smooth radius. This results in improved clogging prevention and less stress on fittings. Additionally, because the wear is distributed equally along the curve rather than concentrated in one area around the edges, the service life of every part is extended.

- Plumbing installations in small spaces, such as behind kitchen cabinets or shelves containing heavy things, are made easier by the flat back of an angle valve. The valve never blocks the way of other pipes and is always accessible.

- A ball valve can be changed by unscrewing the handle from the threaded shaft after using a wrench to undo the two nuts on top of the valve. This reveals the hexagonal nut underneath the handle. To remove it, pull up on the stem and unscrew it using a wrench. It can utilize fresh packing materials to fix any leaks and either replace the old stem or reattach the new one (a process known as reaming).

- Both valves offer safety benefits: angle valves prevent entrapment hazards near shutoff valves, while ball valves eliminate the risk of cutting through supply lines during repairs in places where children might be present.

Ten factors should be taken into account when deciding between ball and angle valves:

Ten factors should be taken into account when deciding between ball and angle valves:

- Performance requirements: Is the application transporting corrosive media, such oil or sewage, or is it operating at high temperatures or pressures? If so, it might have to choose an oil and gas valve or use a material for the valve's body other than steel.

- Maximum Flow Rate (Qmax): What is the maximum flow rate through the valve under normal temperature and pressure conditions at the inlet? Next, confirm that this flow rate can be handled by the valve.

- Exposure Conditions: What is the expected service life cycle of this valve? Vibration, abrasive media, high shock loads, and heat cycles will all be experienced by the valve, potentially reducing its lifespan. When choosing which kind of valve to employ in a particular application, take these aspects into account.

- Port Configuration:Which type of valve to choose—an angle or a ball valve—will depend on the port configuration? For instance, plumbing restrictions may make it necessary to use a ball valve in place of an angle valve if there is insufficient space to install one. Additionally, keep in mind that some pipe connections might not permit the installation of either kind of valve; if this is the case, the user will have fewer options from which to select a suitable valve.

- Installation Cost:Depending on the industrial ball valve provider and the type of valve selected, installation prices will vary; however, in general, angle valves are less expensive because they don't need extra parts like seats, packing nuts, or packing strips. Ball valves, however, usually have a longer lifespan because of their design, which allows it to tolerate greater pressure surges.

Additionally, they are easier to open because their packing nuts don't need to be tightened using equipment like hex keys. Additionally, because ball valves have substantially reduced external dimensions, installing them on a wide range of pipe sizes is simpler and doesn't require reducing flanges or bushings. - Cleaning Cost: Depending on the type of valve selected, cleaning expenses will change. Angle valves do not have any pieces that stick out of the valve opening after installation and collect dirt. Over time, a ball valve may become clogged with dirt and liquids, making it challenging to open and close.

- Operating Cost:

The frequency of operation of each type of valve over the course of a day, week, or month, for example, will determine the operating costs. The primary distinction lies in the fact that an angle valve can be closed without needing to be rotated off its seat, hence reducing internal component wear and tear. Angle valves, on the other hand, only partially close after the operation, whereas ball valves are intended to completely stop the fluid flow. - While research has shown that angled valves can fail by cracking where the valve seats meet due to stress concentration, which can leak even when not under pressure, some people may believe that an angle valve has fewer failure points than a ball valve. On the other hand, because of the accumulation of sediments on valve seats and passageways, ball valves are more prone to corrode and leak.

Without a doubt, angle valves and ball valves are both vital components in industrial settings for a range of industries and applications. Nevertheless, before deciding which type is best for a given application, it is always advisable to be aware of its limitations.