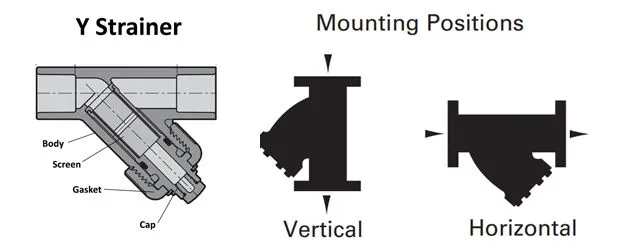

You've come to the correct spot if you've been wondering where to put the Y strainer. Y strainers need to be installed in pipes that run downward, however they can be positioned both vertically and horizontally. Water buildup in the lower pocket, which could lead to erosion, can be avoided using a Y strainer oriented downward. A vertical Y strainer, on the other hand, will stop material from dropping into the upper pocket and being pulled back into the flow.

The Y Strainer: Where Should It Be Placed?

The kind of media passing through the Y strainer determines its orientation. Vertical Y strainers are ideal for fitting liquid media because they let debris fall into the Y's pocket organically. Make sure the Y strainer's legs are arranged to flow downward when you place it in a vertical pipe. By doing this, debris is kept from returning to the flow.

Y-strainers are mechanical separation devices that prevent big particles from flowing by using a wire mesh or perforated metal strainer. JONLOO Valve, a reputable producer of Y-strainers, makes these strainers. They safeguard a range of fluid pipe systems, regardless of their intended use. This pipe fitting will protect your process equipment whether you're using a Y strainer to filter gas or water.

Make sure the arrows on the Y strainer point in the direction of the flow when you install it by aligning the Y's wye side. Additionally, it's critical to confirm that the connectors on the Y's end are square. This is to keep the system from experiencing excessive strain. Make sure the Y strainer is correctly positioned.

The Y Strainer: How to Install It?

The Y strainer must be inserted into the pipeline first. Verify that the flow arrow is pointing in the water's direction. The Y strainer and pipeline must then be aligned. Lastly, you must confirm that it is pointing in the correct direction. You can install the Y strainer after completing all the required details. If you follow the instructions below, installing a Y strainer is easy.

The Y strainer is simple to clean and takes very little work. But it's crucial to keep in mind that letting it fill up too much will damage the filter screen and the system as a whole. Additionally, it's a good idea to clean the filter on a regular basis. Clear the debris from the filter and replace it to clean it. The filter can then be put back in place. Even with its straightforward design, the Y strainer needs to be cleaned frequently to maintain optimal performance.

Make sure you've installed the right kind of pipe before installing a Y strainer. The Y strainer should have the right size to match the system pressure. To prevent getting in the way of the primary flow, it should point downward. Additionally, take into account the pipe support for a large Y strainer. Later breakage will be avoided with these pipe supports. Any plumbing system would benefit greatly from the inclusion of a Y strainer, which can also significantly increase the value of your plumbing.

How to Install a Y Strainer Vertically

Y strainers use wire mesh or perforated strainers to remove solids. Pressurized lines for gas, steam, or liquid are where they are most commonly utilized. Although Y strainers are typically installed horizontally, they can also be positioned vertically. Understanding where in the pipeline the strainer should be installed, ensuring that there is space for screen removal during clean outs, and—above all—aligning the strainer's arrow with the pipeline flow are all necessary for ensuring correct vertical installation of Y strainers.

It's important to remember that if you want to put your Y-strainer vertically, you need to utilize pipes that run downward so that debris can naturally enter the pocket. There is a considerable risk that debris will return to the pipe if they are put in an upward flow.

Steps Before Installation

A few items should be checked before installing your Y strainer, either vertically or horizontally. You must confirm that everything is operational and that the system is within the strainer's capacity (i.e., that the system's pressure rating corresponds with the y-strainer's). You might also need to confirm that the substance is chemically suitable, depending on the media that is passing through your system.

To make sure there are no flaws, you should check all of the seals on the pipe and strainer. Inspecting the pipeline for correct alignment is also necessary. The piping must be straight and not angled if the end connectors are intended to be threaded or soldered. To avoid placing too much strain on the system, make sure the flanges on the pipes to which the Y strainer is being connected are square.

Y Strainer Installation Procedures for a Vertical Setting

Although installing a Y strainer is not difficult, you must ensure that everything is correctly oriented and facing the correct direction.

Step 1: If required, install the blowdown valve at the blow-off connection.

Step 2: Install a pressure gauge at the intake and outflow to guarantee optimal efficiency.

Step 3:In the pipeline, the Y strainer must be placed before any equipment that has to be protected. For instance, the Y strainer need to be positioned on the suction side of the pump if the pump itself has to be protected.

Step 4: Use pipe supports close to the inlet and outlet connections to support the existing pipeline before installing the Y strainer.

Step 5: The strainer's wye side needs to be pointing down. Make sure there is enough room for the screen to be removed from the strainer's wye side.

Step 6: As you insert the Y strainer into the pipeline, make sure the flow arrow on the strainer's body points in the pipeline's direction of flow.

Vertical vs. Horizontal Installation

The media passing through your Y strainer will determine its orientation. The ideal strainer for gas or steam pipe is horizontal. This aids in preventing erosion by preventing water from accumulating inside the pocket. If the piping permits, it might be advantageous to install your Y strainer vertically into the system if the media going through is liquid. By doing this, the debris is kept from being pulled back into the media's flow.

Extending Your Piping System's Life

Because Y strainers can be put either vertically or horizontally, they are a useful addition to many plumbing systems. They are a great option for a strainer when you combine that with the fact that they may be used to move liquid, gas, or steam. The life of your strainer and, consequently, your entire system will be extended if you make sure it is positioned correctly within the piping system and facing the right way.