When choosing an industrial valve, you will face numerous choices. Available materials, proper size, and design (1, 2, or 3 pieces, end connections, etc.) are the key factors to decide which type of valve to use. Equally important is the type of valve seats which directly determines the leakage class of the valve. Before you choose the right valve seats, you must know the following question: Is the medium corrosive? Contains abrasive particles? For high temperature or high pressure? Once you know these things, you will make the right choice. Therefore, the first step to fully understand your craft condition: choose a suitable valve seat.

When choosing an industrial valve, you will face numerous choices. Available materials, proper size, and design (1, 2, or 3 pieces, end connections, etc.) are the key factors to decide which type of valve to use. Equally important is the type of valve seats which directly determines the leakage class of the valve. Before you choose the right valve seats, you must know the following question: Is the medium corrosive? Contains abrasive particles? For high temperature or high pressure? Once you know these things, you will make the right choice. Therefore, the first step to fully understand your craft condition: choose a suitable valve seat.

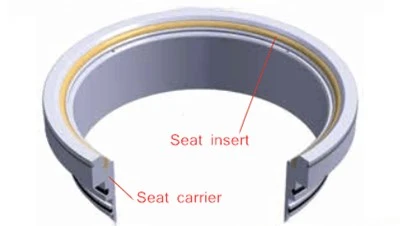

Almost all the industrial valves are metal seat and soft seat available. Both of them offers excellent sealing performance and have their unique and irreplaceable advantages, and inevitably, due to the shortcomings, costs, abrasion resistant performance, working conditions of different materials, metal-seated valves and soft-seated valves both have their markets and long-lasting solutions for critical applications. The table below showed the advantages and disadvantages of metal seat valves and soft seat valves.

Metal seat VS soft seat:

| Valves | Metal seat | Soft seat |

| Material | Copper alloy (for low-pressure valves);

Chrome stainless steel (for medium and high-pressure valves); Satellite Seat Surface (High temperature and pressure valves and highly corrosive valves); Nickel-based alloys (for corrosive media); Metal-ceramic sealing material, etc |

The elastic nonmetallic material such as PTFE(Temperature -50°F to 400°F);

modified PTFE( Temperature -50°F to 450°F); Delrin(High pressure up to 5000psi dependant on valve size and temperature range of -50°F to 180°F); Nylon(Temperature rating -30°F to 200°F; PEEK(Temperature -70°F to 550°F); |

| Manufacturing process | Need grinding, hardening and other precision processing. High precision requirements, complex processing and long production cycle | Easy deformation, low processing accuracy, even free-processing |

| Medium | Hot water, gas, gas, oil, acid and alkali medium | oft seated ball valves are suitable for the working temperature lower than 260℃. Aging easily affected by temperature, used in room temperature environment. Fire protection is needed to prevent leakage at high temperatures. |

| Working pressure | Medium or high pressure above 3.5mpa | Medium or low pressure |

| Working temperature | Metal seated valves are suitable for temperature up to 540℃ (Higher based on the material of body and trim). | Soft seated ball valves are suitable for the working temperature lower than 260℃. Aging easily affected by temperature, used in room temperature environment. Fire protection is needed to prevent leakage at high temperatures. |

| Leakage class(Ball valve) | Class V and VI | VI |

| Cost & Price | Metal seat valve is much higher than soft seat valves | Cheaper than metal seat valves |

| Sealing performance | Wear resistance but easy to leak relatively poor sealing performance | Easy to wear and can achieve a high level of sealing performance or even zero leakage |