Ball valves are designed with cavity relief holes to solve this problem by releasing stored pressure and averting future problems.

This post will explain what a ball valve's cavity relief hole is and how it works.

What is Cavity Relief Hole in Ball Valve

Any pressure that has been trapped in the valve cavity can be released by a tiny drilled hole called a relief hole in the ball valve body. This hole, which can be found in the downstream or upstream end of the valve, is usually made to prevent pressure buildup from damaging or deforming the valve's internal parts.

Cavity Relief in Trunnion Ball Valves

In high-pressure and high-temperature applications where dependable performance is essential, trunnion ball valves with relief holes are employed. This valve's fixed ball, which is held in place by a shaft or trunnion, enables precise control over the opening and closing of the valve.

Trunnion ball valves with a single piston effect seat that automatically releases pressure into the pipeline are produced by certain industrial ball valve vendors. "Self-relieving seats" are built into these valves to relieve pressure.

The media is trapped in the body cavity by the trunnion cavity pressure relief ball valve when the valve is closed. Additionally, when heated, the body cavity's pressure rises against the spring load, pushing the downstream ball valve seat farther from the ball. As a result, the pressure is released.

Cavity Relief in Floating Ball Valves

Like an industrial butterfly valve, floating ball valves are made by valve businesses and are commonly utilized in a variety of sectors because of their affordability and ease of use. A ball that floats in between the two seats of these valves enables a tight seal and low torque operation. When the valve is closed, the media becomes stuck in the cavity. Additionally, the ball has the ability to travel laterally between the two elastomeric seats when closed.

The downstream side of the valve has relief holes drilled into it to provide cavity relief for floating ball valves. By allowing any stored pressure in the valve cavity to be released, these relief holes help prevent pressure buildup from damaging the valve and other equipment. By looking for fluid in the cavity, these relief holes can also be utilized to confirm that the valve is closed.

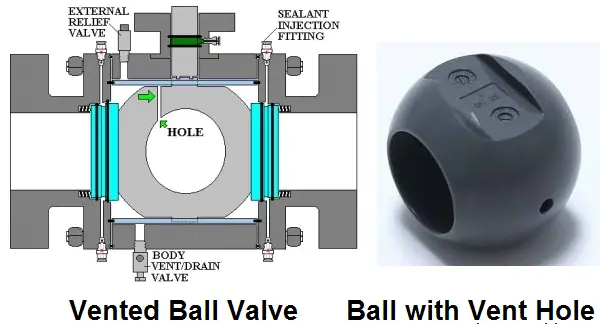

What is the Purpose of Vented Ball Valves

The main objective of vented ball valves is to offer a dependable and secure method for releasing gas or liquid from tanks or pipes. Sometimes variations in temperature or pressure can cause gases or liquids to accumulate pressure. Hazardous conditions like explosions or other safety issues may result from this. By offering a dependable and secure method of expelling liquids or gases that have been trapped, vented ball valves assist in reducing these dangers.

Ventilated ball valves can also be used to control the flow of liquids or gases through pipelines. The purpose of the vented ball valve is to precisely regulate the fluid flow rate in the pipeline. The flow rate can be adjusted manually or automatically with the use of an actuator. This makes the valve suitable for a variety of uses where accurate flow control is crucial.

Moreover, vented ball valves are made for simple cleaning and maintenance. These valves' straightforward construction makes cleaning and disassembly a breeze. This makes them perfect for use in industries like food processing and pharmaceuticals where sanitation and hygiene are essential.

Cavity Relief Testing for Valves

To find liquids or other media with heat capacity trapped in the body cavity, cavity relief testing is necessary. It is advised in situations where the media is heated or experiences significant fluctuations in pressure and temperature over time.

The cavity relief tests that API 6D specifies are listed below.

Trunnion Ball Valves

- Set the valve to half-open to let in water. Open the valve at both ends to allow water to spill out of the test connections.

- Apply pressure to the valve cavity and record the pressure relief that occurs when one seat in the valve releases the cavity pressure into the valve end.

- Until the second seat is freed, maintain raising the cavity pressure while utilizing a sort of valve with a second seat relief. Observe the relief pressure on the second seat.

- Relieve at a pressure greater than 1.33 times the valve pressure rating for optimal performance.

Floating Ball Valves

- Apply 1.33 times the valve pressure rating of pressure while the valve is half-open.

- Let each end recover to atmospheric pressure after closing the valve.

- To see if the test media that was caught in the cavity has been released, partially open the valve. The testing fails if pressurizing media become stuck in the cavity.

The Functions of Ball Valve Cavity Relief

A ball valve's cavity relief element performs crucial roles in preserving both the valve's functionality and safety. These are a few of their uses.:

- Overpressure protection: Ball valve cavity relief is intended to guard against damage from overpressure in the valve cavity that could harm the valve body and other parts. At a set pressure, the relief mechanism opens to remove excess pressure and stop dangerous situations like leaks or explosions.

- Prevents damage to seals or seats from overpressure: The cavity relief hole in a ball valve aids in maintaining the valve's sealing capabilities. This guarantees the valve's ability to function properly and stop fluid leaks.

- Easy maintenance is made possible by the cavity pressure relief ball valve, which offers a way to release pressure while disassembling or repairing the valve. This makes valve maintenance safe and simple. This raises the dependability of the valve and lowers the possibility of mishaps during maintenance.

- Regular fluid flow is made possible by the cavity relief mechanism, which keeps the valve cavity's pressure constant and makes it easier to precisely control fluid flow. This improves the effectiveness and function of the valve.

- Enhances safety: By guaranteeing that the relief mechanism is operating correctly, a ball valve with a relief hole raises the safety of the valve. This lowers the possibility of mishaps and improves the valve's overall dependability.

Conclusion

Ball valve cavity relief is essential for protecting ball valves from harm and guaranteeing the dependable and safe operation of a range of industrial applications. These relief holes are intended to release trapped pressure in trunnion ball valves and floating ball valves, thereby averting possible problems such as leakage, valve damage, and even system failure.

JONLOO, one of the top producers of valves in China, offers a large selection of high-quality ball valves with relief holes. Our highly skilled crew manufactures floating ball and trunnion ball valves, which aid in the release of stored pressure, in our expansive manufacturing facility that is outfitted with state-of-the-art machinery and technology. Our valves are made to guarantee that mechanical systems operate at a high level for the duration of their service lives.