What Is a Fail Close Valve?

An industrial safety valve called a fail close valve is made to shut automatically in the case of a system failure. This kind of valve is frequently utilized in crucial situations when a pressure drop could have disastrous results. Fail close valves are usually installed in places like pressure vessels, chemical storage tanks, and pipelines where leaks are possible.

A monitoring system that can identify when a failure has occurred is usually connected to a fail close valve when it is placed in a system. When a breakdown is identified, the fail close valve immediately shuts, stopping additional pressure loss. Depending on how severe the failure is, the fail-close valve may occasionally open to relieve pressure before it closes.

Pros Of Fail Close Valve

The use of fail-close valves has several advantages. The following are some benefits of fail-close valves:

- Enhanced safety — By turning off automatically in the case of a power outage, fail close valves can help avoid accidents.

- Lower costs –By shielding equipment from harm in an emergency, fail close valves can help cut expenditures.

- Enhanced effectiveness — By lowering the requirement for manual intervention in case of an emergency, fail shut valves can enhance the effectiveness of your operations.

- Enhanced reliability--Compared to manual valves, which are frequently forgotten or improperly maintained, fail shut valves are typically more dependable.

- By guarding against disruptions in the process, it can lower downtime and the related expenses.

Cons Of Fail Close Valve

The application of fail close valves has numerous drawbacks. Failure-close valve drawbacks include the following:

- The fail close valve is readily broken and has a low level of durability.

- Water pressure issues may arise if the fail shut valve is not placed properly.

- It can be difficult to use the fail shut valve, especially if you're not mechanically inclined.

- It is also known that the fail-close valve will occasionally leak, wasting water and possibly damaging the surrounding region.

- Finally, the cost of the fail shut valve may discourage some individuals from installing it.

- Unexpected and hazardous pressure spikes can result from a fail-close valve.

- An ineffective close valve can increase a system's needless expense and complexity.

- It may become difficult to replace or repair the valve if it becomes stuck or frozen in place.

- It might be challenging to install and maintain fail shut valves.

What Is a Fail Open Valve?

A fail open valve is a particular kind of valve that is intended to remain open in the event that the system fails. This kind of valve is usually utilized in systems, like gas or water lines, where it is essential to keep the flow consistent. A vital component of many systems, fail open valves can aid in preventing damage and malfunctions. A fail open valve can be the best option when building a system that must have a steady flow.

Pros Of Fail Open Valve

Here are five pros of using a fail open valve:

- Fail open valves can halt harmful situations: If there is no method to stop the flow of gas or fluid during a power loss, there may be a risk. For instance, a fail open valve can stop hazardous chemicals or gas from escaping in the case of a pipeline breach.

- Pressure must be maintained in some systems, and fail-open valves can assist in doing so. Maintaining system pressure during a power outage can be facilitated by the use of a fail open valve.

- Backflow prevention is crucial in certain systems, and fail open valves can aid in this regard. A fail-open valve can assist in making sure that gas or fluid does not leak back into the system, which could be dangerous or result in damage.

- Flow regulation is important in certain systems, and fail-open valves can assist in this regard. In the event of a power failure, a fail open valve can help guarantee that the flow is kept at a safe level.

- Emergency use of fail open valves: In certain situations, a fail open valve can be used to halt the flow of gas or fluid in an emergency. For instance, a fail open valve can stop the leakage of hazardous gas or chemicals in the event of a pipeline breach.

Cons Of Fail Open Valve

Failed-open valves have numerous advantages, but they may also have certain disadvantages. Five drawbacks of fail-open valves are as follows:

- The fact that fail open valves are prone to leaking is one of their biggest drawbacks. The incorrect installation of the valve may cause fluids, such as water, to seep through. This may result in expensive repairs or harm to your house or place of business.

- Closing fail-open valves can also be difficult. It might not be simple to switch off the valve if it is not put appropriately. This could be an issue in the event of an emergency or if you suddenly need to turn off the water.

- The fact that fail open valves may be noisy is another drawback. When the valve is turned on or off, it could generate a loud pounding sound if it is not placed correctly. This may be inconvenient and distracting, especially if there is a neighboring business.

- Failed-open valves can also be challenging to maintain. Cleaning and repairing the valve could be challenging if it is not installed appropriately. This may be an issue if the valve is frequently used or if it is situated in a challenging-to-reach place.

Key Difference Between Fail Close And Fail Open Valve

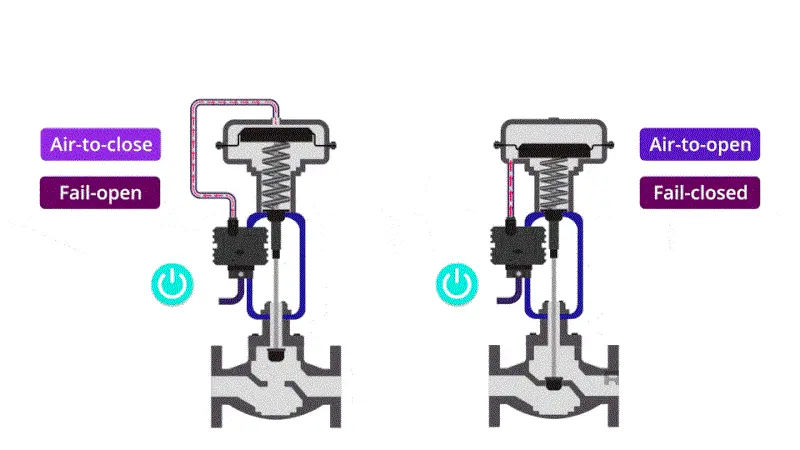

Instrument valves are made to react automatically to a signal from a controller by opening or closing. This enables automated liquid and gas flow control in process systems. The two primary instrument valves are the fail shut and fail open valves. Fail shut and fail open valves differ significantly in a few important ways. These five key distinctions between fail open and fail shut valves are highlighted.

- In the case of a malfunction or power outage, fail open valves remain open while fail close valves close.

- In critical applications where a flow loss could be dangerous, fail shut valves are frequently utilized. Conversely, fail open valves are frequently employed in situations where a flow loss is not essential.

- Failure close valves are made to take more force to open than failure open valves due to their design.

- Because of their greater functionality, fail shut valves are usually more expensive than fail open valves.

- Because they need to be able to endure the greater effort needed to open them, fail close valves are usually constructed from higher grade materials than fail open valves.

Conclusion

There are two distinct kinds of valves with distinct uses: fail open and fail close valves. Failure open valves permit the passage of gases or liquids, while failure close valves stop the flow of either. Fail open valves will stay open in the event of a power outage, but fail close valves will close. This is the primary distinction between the two.