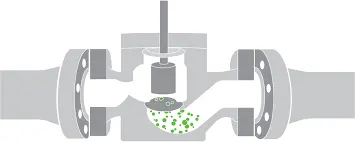

Unexpected cavitation can seriously damage the internal components of the control valve and possibly result in a catastrophic system failure. Therefore, it's critical to comprehend valve cavitation, including its causes, effects, and potential mitigation strategies.

What is Valve Cavitation

By calculating the volume of noise and vibration produced while a valve is operating, cavitation in the valve can be measured. Noise levels and vibrations at high frequencies are common signs of valve cavitation. These tests can assist detect any damage to valve components and offer important information regarding the degree of cavitation.

The computation of valve cavitation can be done at three fundamental levels:

- Incipient: The initial phase of cavitation during which sporadic popping sounds are audible.

- Constant: A continuous rumbling noise linked to the beginning of the deterioration to the valve.

- Choked: The fluid vaporization at the valve's port reaches supersonic velocity, obstructing the smooth flow through the valve.

What Leads to Cavitation in a Control Valve?

- High Velocity: High velocities of the liquid passing through the valve can produce low-pressure zones where vapor bubbles can occur. This is especially true when forcing a liquid through a tiny aperture, like the opening of a narrow valve.

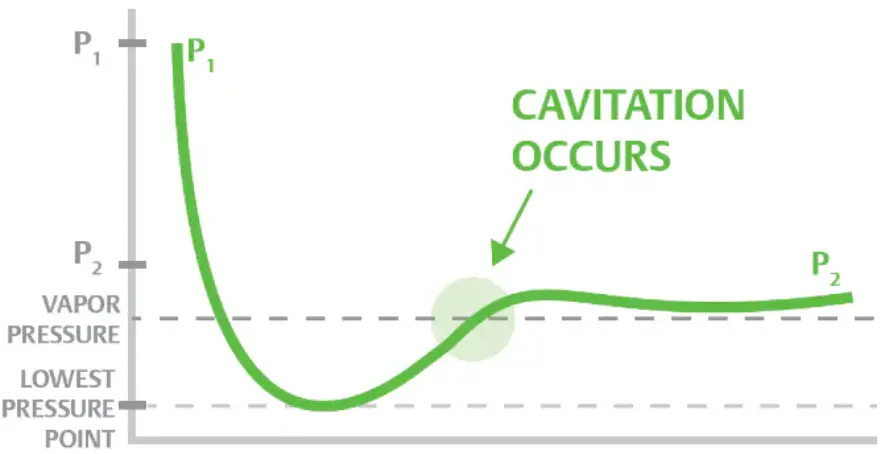

- Pressure Drop: There is frequently a pressure drop between the inlet and outlet as the liquid passes through the valve. Cavitation may result from vaporization of the liquid due to an excessive pressure drop.

- Temperature: As a liquid reaches its boiling point at a lower pressure due to high temperatures, there is a greater chance of cavitation.

- Liquid Properties: Different liquids have varying susceptibilities to cavitation. For instance, cavitation is more likely to occur in liquids with low vapor pressure or high viscosity.

- Design of the valve: Cavitation may also result from the valve's design. Sharp edges or sudden direction changes on the valve can cause turbulence in the liquid flow, which can result in cavitation.

How Control Valves Are Affected by Cavitation

A control valve that has cavitation may become less effective, require more maintenance, or even fail. Vapor bubbles can quickly build and burst, eroding and pitting valve components and resulting in leaks, lower flow rates, and less precise control.

This may impair the valve's capacity to maintain the appropriate pressure, temperature, or flow rate, which could lead to unstable systems or inadequate process control. In extreme circumstances, the impact of the collapsing vapor bubbles can damage or even dissolve valve components, such as seats, plugs, and stems.

Additionally, excessive noise and vibration caused by cavitation may be detrimental to both personnel and system components. Vibrating valve components due to high-frequency pressure waves can result in mechanical wear and even failure. Overly loud noise levels cause workplace disturbance, communication interference, and noise regulation violations.

Cavitation Prevention Solutions in Control Valves

Control valve cavitation must be prevented in order to guarantee appropriate operation and prevent any system damage. Although there are many different anti-cavitation relief valve techniques, they can be divided into two groups: avoidance and design.

Avoidance

Avoiding cavitation valves completely is the finest anti-cavitation valve precaution. These are the actions that can be taken.- Lower the fluid velocity: A high fluid velocity is one of the main reasons for cavitation. Consequently, cavitation can be avoided by lowering the fluid's velocity, which can be achieved by enlarging the pipe or decreasing the flow rate.

- Boost system pressure: Increasing the system pressure will also lessen the chance of cavitation by lowering the pressure drop across the valve.

- Adjust the fluid's properties: Varying the fluid's viscosity or temperature can also aid in preventing cavitation.

- Pick the appropriate valve: Work together with a reputable valve supplier to choose a valve that is more appropriate for your particular application. Choosing a valve with a higher capacity, a different type of valve, or a different trim material, for instance, can help lower the risk of cavitation.

Design

If cavitation cannot be avoided, the valve needs to be made to be able to manage it and lessen its consequences. Three anti-cavitation relief valve techniques can be applied to accomplish this. In valve designs, two or perhaps all of these measurements are frequently used.

- Robustness: This refers to the important valve parts that would be subjected to cavitation being manufactured from high-strength materials. Robust materials will help withstand the damage for a longer amount of time, even though cavitation may eventually harm the interior components of the valve.

- Isolation: To prevent microjets and shock waves from harming the valve components, the collapsing bubbles must be redirected or directed toward the center of the flow stream.

- Elimination: By allowing the pressure to drop gradually rather than all at once, cavitation is reduced. There are frequently greater dips in a single pressure decrease, which leads to fall below the liquid vapor pressure. Nevertheless, if the pressure drop is measured three or four times in succession, the pressure drop will be abolished and the pressure will stay higher than the vapor pressure.

Choose the Appropriate Manufacturer of Valve to Prevent Cavitation

Choosing the correct valve manufacturer has a significant impact on how reliable your valve is in preventing cavitation. JONLOO Valve is a skilled and knowledgeable producer of all types of control valves suitable for use in a range of industries. Produced by a highly skilled research and development team with extensive experience in reducing cavitation, the valves are incredibly robust and useful.

This sets us apart from the competitors, including the market's industrial ball valve suppliers. Our dependable supply network guarantees that only premium products that meet industry requirements are utilized. By doing this, we are able to supply you cavitation-resistant valves, which improve system performance and lower maintenance costs.

Conclusion

In many fluid systems, valve cavitation is a serious issue that can lead to equipment damage, decreased efficiency, and safety risks. It is essential to comprehend its causes and effects in order to manage it successfully.

The effects of cavitation can be lessened with proper anti-cavitation valve selection, design, and maintenance. In general, preventing valve cavitation necessitates a thorough strategy that includes figuring out the underlying reasons, putting the right preventative measures in place, and routinely checking and maintaining the system to make sure it's operating at peak efficiency.