A Parallel Slide Gate Valve: What Is It?

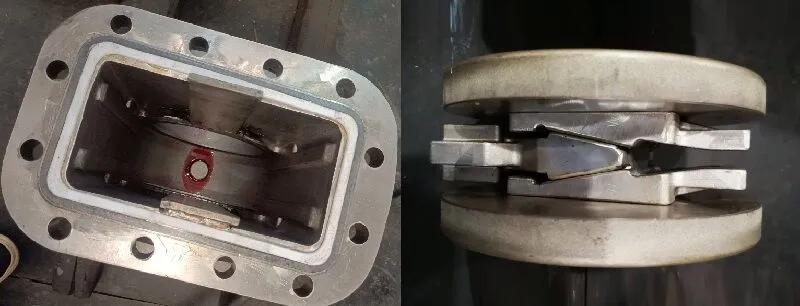

Full bore fluid flow with no direction change is accomplished using slide gate valves, which are linear motion valves. They are made to offer a productive way to regulate the flow of dry bulk materials that are free-flowing. It is the perfect valve for transferring and stopping fluid flow, and it works well with pipelines used in industrial processes, such as gas pipes, petrochemical oil depots, and crude oil pipelines. This kind of valve is frequently referred to as a Parallel Slide Gate valve since its face is primarily parallel. They are typically not utilized to control flow and are either fully open or fully closed. To manage and control the liquid flow, slide gate valves can also be fitted at an oil pump's outlet. The image below depicts a common slide gate valve:

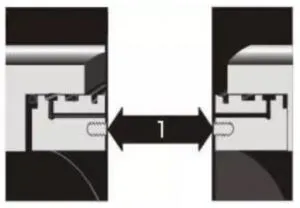

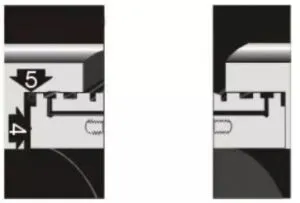

The valve body, bonnet, disc assembly, stem, and top works make up the parallel gate; each side of the valve is capable of withstanding a complete differential pressure. Internal pressure and spring force work together to generate a replacement double-disc seal with double bleeding and blocking (DBB). When pressure builds up in the central chamber, the floating seat may automatically release the pressure. The cavity pressure will be released into the channel when the pressure inside the cavity is higher than the pressure inside the channel. The middle chamber's pressure will be released into the upstream side channel when the upstream pressure of the channel exceeds the downstream pressure (when the valve is closed). The pressure in the middle chamber can cause bilateral channels to discharge when the upstream and downstream pressures of the channel are equal (the valve is fully open). When the pressure is released, the valve seat automatically resets.

- The disc closes and the PTFE sealing ring on the seat surface creates the first seal when the pressure inside the valve (cavity, inlet, and outflow) is equal or zero. Each time the valve is opened or closed, the seat ring can automatically clean the sealing surface on both sides of the disc.

- The inlet side disc is subjected to medium pressure, which forces the disc to move toward the PTFE ring on the exit seat. The disc compresses until it compaction occurs in the metal valve seat sealing surface, creating a hard and soft double seal. The export seat is also pushed to the body seat hole on the end face of the O-ring seat ring and valve sealing.

- The inlet seat is forced to travel to the disc by the medium pressure, and the inlet seal is formed following the pressure release in the cavity. The O-ring ensures that the seat outer ring and valve body are sealed at this moment when the inlet seat creates a soft PTFE to metal and metal-to-metal seal.

- The valve automatically releases pressure. The inlet seat is forced to the disc end of the upstream seat hole under the pressure differential when the pressure in the valve body's cavity exceeds the pipe pressure. The excess pressure between the upstream seat and the valve body's disc sealing surface is then released into the upstream pipe.

Parallel slide gate valve characteristics and advantages

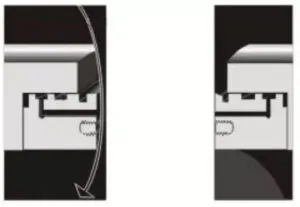

- The sealing surfaces of the parallel slide gate valve are free of propensity, notch, and indent because it closes by sliding action rather than the customary compression. A longer lifespan for the discs and seat sealing surfaces, as well as improved disc tightness on the seat ring, can arise from this action.

- A parallel-slide gate valve can clean seats by making close contact with them when closing. As a result, any impurities or tendencies that may have developed on the seats and discs are removed, leaving the sealing contact clear of unwanted particles. Additionally, it ensures long life and lessens seat-bearing load. Since the entire surface is sealed, the wide flat seating can lessen the impact of small surface problems.

- Since the sealing is achieved by sliding rather than by compression, no extra power or last burst of torque is needed to make the seating leak-tight. Furthermore, since considerable energy is not required to open the valves, the valve uses little energy.

- Compared to the wedge type, the parallel sliding gate valve's actuator size can be substantially smaller. On this valve, hammering or striking hand wheels is typically not required.

- The trim is less stressed and fatigued due to the low torque operation. This results in increased leak-tight reliability and a longer lifespan.

- The precise location of the stem is not very important when the valve is closed. The variations in the materials' coefficients of thermal expansion are therefore not an issue. Additionally, generic position switches can be used to halt the actuators.

- Parallel sliding gate valves will never jam, unlike wedge gate valves, which may do so due to body contraction.

- For wedge gate valves to stay in line when shutting under full flow conditions, the wedge needs placement guides on its slides. Due to their tendency to wear and lack of robust materials, these guides may eventually clog.

Comparing Wedge Gate Valve with Parallel Slide Gate Valve

When it comes to tight, dependable shut-off in water and steam service, our Parallel Slide Gate Valve design has numerous advantages over double disc wedge gate valves.

One of these benefits stems from the way these valves are seated. Because our Parallel Slide Gate Valve uses position seating, the downstream disc is held firmly against the downstream seat by the line force in the system, which helps to seal the valve seat. In contrast, a double-disc wedge gate valve uses torque force to provide shut-off by wedgeing the disc into the valve body. of order to enable seating, the valve seat of a double disc wedge gate must genuinely deform. In a short amount of time, this may cause the seat to permanently distort, creating a leak channel. Additionally, compared to torque seating, position seating uses less torque to open and close. This lowers operating expenses by enabling our valve to be operated by a smaller actuator.

Additionally, our valve's broad, flat seating surface provides a sealing surface area advantage. Up to two inches can be found on the seating surface of our valve. This stops little dings or seat deterioration from turning into a leak. A twin disc wedge gate valve has a relatively small sitting surface area since it depends on a line contact seating surface. The likelihood that a little seat irregularity will develop into a leak channel is increased by a line contact seat. Additionally, our valve's larger seating surface allows bearing stresses to be distributed over a wider region, minimizing seat wear brought on by regular use. A parallel slide gate eliminates the need for disc reseating once a valve closes and cools down because of its position-seated design and wide flat seats. Because of its torque-seated design, a double disc wedge gate may need to be reseated after cooling because contraction can cause a previously sufficient seal to become loose.

Our Parallel Slide Gate Valve provides protection against thermally locking a valve in the closed position in addition to the previously mentioned benefits. When a hot valve that is closed starts to cool, this can happen. The discs may become trapped between the body seats if the larger valve body cools more quickly than the disk. In order to separate the disc from its seat, more torque will be needed. Because of its position-seated design and two independent discs, the Parallel Slide Gate Valve can compensate for different rates of thermal contraction, which helps to avoid thermal binding. However, because the seating concept of a double disc wedge gate requires the disc to be wedged into the body, it is unable to account for different rates of contraction. As a result, the valve may jam closed, requiring more torque than is available to open it.

The parallel slide gate valve's seating theory is significantly superior to that of the double disc wedge gate valve; it uses internal forces to produce dependable tight sealing and has a more forgiving seating approach that accounts for little seat deviations.

The problems of solid wedge gate valves:

- Thermal binding causes the disc opening to malfunction. Thermal binding in wedge-type valves is brought on by dimensional interference between the wedge and seat as a result of thermal expansion and temperature variations. At high levels, valves are frequently utilized.

- Due to thermal deformation, leakage issues Enough surface pressure must exist between the discs and seats since the valve is sealed by compression. To be able to withstand, the bodies should be made thick and sturdy.