Introduction

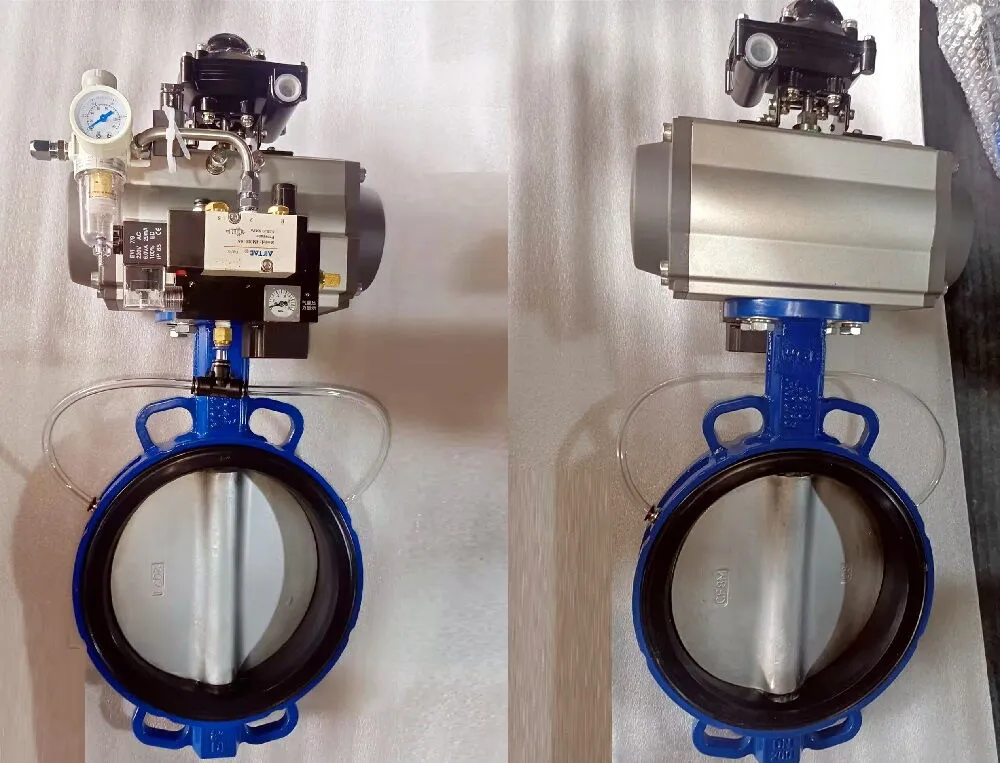

Furthermore, depending on the demands of the particular application, these valves can be operated manually, pneumatically, or electrically. Because they make cleaning easier and avoid product contamination, they are frequently employed in the food processing, chemical, pharmaceutical, and mining industries. In addition to having a long service life and requiring little maintenance, inflatable seat butterfly valves are an affordable option for a variety of industrial applications. They are a flexible solution that can satisfy a range of industrial demands thanks to their distinctive style and abundance of features.

A succinct description of the function of butterfly valves in fluid control systems.

Butterfly valves are important components of fluid control systems. These quarter-turn rotational motion devices are crucial for effective fluid management because they use a rotary disc to control, permit, or hinder the flow of fluids inside a pipeline system. Many industries use them because of their affordable price and straightforward but efficient design. When compared to other valve options like ball and check valves, the lightweight and space-saving characteristics of butterfly valves further enhance their appeal. These valves, which are specifically made for fast shut-off in pipe systems, got their name from the way their body and closure components resemble butterfly wings. Butterfly valves have the special ability to control and lessen flow with ease because of their circular plate feature. This is only one of their many advantages.

An introduction to the special properties of inflatable seat butterfly valves.

As their name implies, inflatable seat butterfly valves differ from other varieties of butterfly valves due to their special inflatable seat characteristic. With the help of air pressure, this creative design expands the valve's seat against the disc, distributing pressure evenly and creating a bubble-tight seal that reduces the possibility of leaks. These valves are known for their efficaciousness as isolation valves, especially in situations involving the production of power where tight isolation is necessary. Like other butterfly valves, the inflatable seat butterfly valve is designed with a disc-like closure component that may be turned 90 degrees or less to open or close the valve. The valve also consists of a body, seat, disc, stem, and actuator, each of which comes in a variety of materials known as "trim features." Many industries use the inflatable seat butterfly valve because of its unique design, which guarantees excellent fluid flow control and is also reasonably priced.

Understanding Inflatable Seat Butterfly Valves

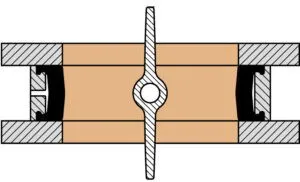

A specific subset of the larger butterfly valve family, inflatable seat butterfly valves are made to handle a wide variety of materials and provide outstanding performance even in harsh environments. These valves are essentially made up of an inflatable seat that, when inflated, creates a tight seal to stop any substance from leaking out of the valve. The valve lets the material flow freely when it is deflated. When handling granular or powdered items that could otherwise become caught in the valve and cause blockages, this functionality is especially helpful. These valves usually have a disc installed on a spinning shaft as part of their design. The valve, which regulates the material flow, is opened or closed by turning the disc. This fundamental function is improved by the inflatable seat, which offers a tighter seal and improved flow management. Inflatable seat butterfly valves are used in a number of industries, such as food processing, pharmaceuticals, and mining, where they help maintain hygiene standards, prevent contamination, and make cleaning and maintenance easier. This is because of their distinctive design and superior sealing capabilities. They are a great option for tough industrial applications because of their dependability and longevity.

The definition and fundamental idea of butterfly valves for inflated seats.

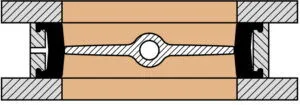

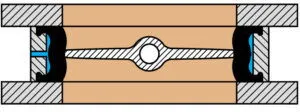

One special kind of butterfly valve, known for its excellent fluid flow control, is the inflatable seat butterfly valve. The body, disc, stem, and unique inflatable seat are the primary components that make up the fundamental design of an inflatable seat butterfly valve. inflated seat butterfly valves use an inflated seal or bladder, as opposed to conventional butterfly valves that rely on friction for sealing. To create a tight seal against the disc, air pressure is used to inflate or deflate this unique characteristic. Inflating the seal results in a bubble-tight shut-off that stops leaks. Conversely, the valve permits unrestricted material flow when the seal is deflated. To control the flow of fluids, a butterfly disc that is positioned on a shaft inside the valve body rotates on its own axis. With their enhanced sealing mechanism and increased operating efficiency, inflatable seat butterfly valves are a dependable and effective solution for a range of industrial applications thanks to their creative design.

An explanation of the operation of inflated seat butterfly valves.

Essential parts of an inflated seat butterfly valve.

The functioning of an inflatable seat butterfly valve is dependent on a number of essential parts. The inflatable seat, a special feature that expands to form a tight seal against the disc when the valve is closed, located at the center of the valve. This guarantees there are no leaks and keeps the product from becoming contaminated. The disc is another crucial element; it is usually composed of sturdy materials like carbon steel or stainless steel. It spins to control the fluid flow by opening or closing the valve. The stem, which is attached to the disc and protrudes outside the valve, permits external disc position adjustment. These interior parts are housed in the valve body, which is often made of sturdy, corrosion-resistant material and serves to join the valve to the pipeline. Ultimately, the actuator—which may be electric, pneumatic, or manual—manages the stem and disc's movement and determines whether the valve is open or closed. An inflatable seat butterfly valve's overall performance and efficiency are enhanced by each of these parts.

Design Features of Inflatable Seat Butterfly Valves

Butterfly valves for inflatable seats have a creative design that blends the conventional features of a butterfly valve with the special attribute of an inflatable seat. The basic design consists of a disc that is usually installed on a revolving shaft. The disc opens or closes the valve to control the flow of fluid when it is rotated. The inflated seat, however, is what distinguishes these valves. Air pressure is used to cause this seat to expand and shrink, giving it a tighter seal while inflated and allowing for unrestricted passage when deflated. This two-fold purpose removes the possibility of materials becoming caught in the valve, a problem that frequently arises when dealing with powdered or granular materials.

Because the inflatable seat is made of sturdy materials that can withstand a variety of chemicals and temperatures, it will last and function reliably even in harsh industrial settings. Additionally, these materials have excellent sealing qualities, which stop any material under control from leaking. This capability is especially helpful in sectors of the economy where contamination control and upholding hygienic standards are critical.

The ease of maintenance is another important feature of the design. The inflatable seat butterfly valve's straightforward design makes it simple to clean and replace parts, which lowers downtime and boosts operational effectiveness. Furthermore, depending on the particular needs of the application, the valve's body can be constructed from a variety of materials, such as carbon steel, stainless steel, or other alloys.

Another crucial part that offers flexibility in operation is the actuator, which can be automated or operated manually. Pneumatic, electric, or hydraulic automated actuators enable accurate fluid flow regulation and remote control. Last but not least, the trim elements—the disc, stem, and seat—can be altered in a variety of materials to meet the demands of certain applications.

All things considered, the design characteristics of inflatable seat butterfly valves provide a special combination of performance, robustness, and versatility, which makes them a great option for a variety of industries.

In-depth analysis of inflatable seat butterfly valve design features.

The design of inflatable seat butterfly valves is distinctive in a few ways. A butterfly disc situated on a shaft inside the valve body serves as the valve's core. This disk has the ability to rotate, allowing or preventing the passage of materials (ScienceDirect). But what makes these valves unique is their inflatable bladder or seal. When inflated, this seal creates a tight seal and evenly distributes pressure against the disc by inflating or deflating in response to air pressure (Posi-flate, Hawsd). In comparison to conventional butterfly valves, this design has better sealing capabilities, preventing leaks and cross-contamination. Long life and durability are further ensured by the use of industrial-grade components (Value Butterfly Valves). These valves are perfect for heavy-duty applications because of the seat's unique ability to withstand harsh conditions. It expands under air pressure to give increased sealing area and an even pressure distribution (GlobalSpec, McRae Engineering, Bulk Solids Today). Lastly, the use of these valves in power generation as isolation valves demonstrates their versatility even more (Airmatic).

How the efficiency and functionality of the valve are enhanced by these design elements.

An inflated seat butterfly valve's usefulness and efficiency are largely enhanced by its design elements. When inflated, the inflatable seat, which is the main component, creates an airtight seal that guarantees no leaks and avoids material cross-contamination. This is especially helpful in sectors like food processing and pharmaceuticals where purity and hygiene are crucial. These valves are extremely adjustable to different flow requirements because of the disc's capacity to revolve, which gives precise control over the fluid flow. The sturdy construction of the valve guarantees long-term performance and durability even in challenging circumstances, enhancing the overall effectiveness of the system into which it is integrated. The stem, which protrudes outside the valve, improves use by making it simple to adjust the disc's position. Last but not least, the actuator—whether electric, pneumatic, or manual—offers versatility in valve control, meeting a range of operational requirements and conditions. The inflatable seat butterfly valve is a dependable, adaptable, and effective flow control solution for a range of industrial applications thanks to these unique design elements.

Pay attention to details like minimal torque, positive shutdown, and seal inflation.

The special characteristics of inflatable seat butterfly valves, like seal inflation, positive shutdown, and reduced torque, set them apart. One of these valves' most inventive features is the seal inflation. The seat uses pressurized air or fluid to inflate when it's necessary to stop the material flow, expanding to form a tight seal against the disc. Positive shutdown, or complete flow cessation with zero leakage, is ensured by this inflated seal. It is an extraordinarily successful strategy for avoiding cross-contamination and upholding strict hygienic standards in delicate industrial processes. These valves are also made to run with the least amount of torque possible. By lowering friction between the seat and the disc, the inflatable seat makes it possible for the disc to rotate easily and with less force. This effective design not only makes the valve easier to use, but it also prolongs its life by minimizing component wear and tear. Because of their seal inflation, positive shutdown, and reduced torque, inflatable seat butterfly valves are therefore incredibly effective and dependable at managing material flow.

Unique Applications of Inflatable Seat Butterfly Valves

Because of their unique shape and functioning, inflatable seat butterfly valves have a wide range of unique uses across numerous sectors. These valves are highly valued in the food processing and pharmaceutical industries due to their capacity to avoid cross-contamination. The inflatable seat's tight seal guarantees that there is no leaking, upholding strict hygienic guidelines and the integrity of the product. They are also employed in chemical industries where it is customary to handle caustic and harsh materials. Because the inflatable seat and the disc are made of sturdy materials that can survive tough situations, they provide dependable performance while maintaining safety.

These valves are used to regulate the flow of abrasive materials in the cement and mining sectors. Because to their special design, there is less material buildup and wear, which lowers maintenance requirements and boosts operational effectiveness. They are therefore perfect for regulating the flow of materials that are granular or powdered. These valves are also advantageous to the oil and gas sector, especially in pipeline applications where leak-proof sealing is crucial. Low differential pressures do not compromise the outstanding shut-off capabilities of the inflatable seat, which makes it appropriate for low-pressure gas transmission lines.

Furthermore, these valves in water treatment facilities efficiently control the flow of water and other liquids while withstanding the caustic effects of some of the chemicals employed in the procedure. They are helpful in HVAC systems for managing air flow because of their resistance to varying temperatures. These valves have another unusual usage in pneumatic conveying systems, where they are employed to isolate various system components during maintenance or in the event of a blockage.

Overall, inflatable seat butterfly valves are adaptable to a wide range of working situations and handle a variety of media, including gases, liquids, and granular particles. This is due to their strong design and distinctive features, which make them useful in a multitude of sectors.

An overview of the different applications for inflatable seat butterfly valves.

Because of its exceptional sealing properties and distinctive design, inflatable seat butterfly valves are used in a wide range of sectors. They are especially helpful in the food and beverage sector since they guard against contamination and guarantee that hygienic requirements are upheld. These valves are also used by the pharmaceutical industry to guarantee the purity of drugs and other goods. Because of its durable design that can withstand a wide range of chemicals, they are utilized in the chemical industry for handling caustic and hazardous products. These valves are also used in the power generation industry, where they improve safety, reduce leaks, and offer efficient isolation. They are used in the mining industry to handle gritty and abrasive minerals because the inflated seat reduces material build-up and valve wear. They are also utilized to control fluid flow in wastewater treatment facilities. All things considered, inflatable seat butterfly valves are a useful tool in many industries due to their adaptability.

Case studies of distinctive applications that illustrate how various sectors leverage on the design elements of these valves.

Numerous case studies demonstrate the wide range of uses that valves' distinctive design features find in various industries. For example, metal-seated ball valves are employed in supercritical steam conditions in power plants because of their strong design, which allows them to endure fast high-pressure and temperature fluctuations (Springer). An additional study emphasizes the applications of flow-mode MR valves in optical finishing and the automobile industry. By utilizing the rheology of smart fluids, these valves showcase the inventive use of material science (MDPI). Additionally, geothermal power plants make special use of valves by leveraging the fundamental science that controls the operations. Moreover, valves play a role in environmental management since they are used in stormwater systems to reduce flood risk (ASCE Library). Healthcare uses of valves are significant since they are utilized to treat conditions such as Gaucher's disease (ScienceDirect). These case studies demonstrate how the design characteristics of valves—such as their resilience, adjustability, and accurate control—are emphasized in various industries, enhancing their usefulness and adaptability.

The food and beverage sector, medicines, chemical processing facilities, etc. are a few specific examples.

Chemical processing facilities, pharmaceutical companies, and the food and beverage industry all depend on inflatable seat butterfly valves. These valves are utilized, for example, in the food and beverage business in procedures involving semi-solid foods like purees and sauces as well as liquid foods like milk, beer, and juices. When closed, they guarantee a tight seal that keeps food products from leaking or cross-contaminating one another, which is essential for upholding hygienic standards and product quality.

These valves are essential to processes involving the flow of sensitive compounds in the pharmaceutical industry. In an industry where purity is crucial, the inflatable seat offers an extraordinary degree of sealing, guaranteeing that there is no contamination. This is especially crucial when making medications because even small contaminations can have detrimental effects.

These valves are also very important in chemical processing facilities. The inflatable seat butterfly valves' capacity to offer a safe shut-off is crucial given the nature of the liquids they handle, many of which are hazardous or corrosive. It guarantees the safety of the plant's personnel as well as preventing the leakage of dangerous materials. Moreover, their sturdy construction makes it possible for them to endure the challenging circumstances commonly seen in chemical plants, extending their lifespan and dependability.

Advantages of Using Butterfly Valves with Inflatable Seats

Because of their many advantages, inflatable seat butterfly valves are a common option across a range of sectors. Their superior sealing properties are one of the main benefits. In order to guarantee no leaks and avoid cross-contamination, the inflated seat creates a tight seal against the disc. This is especially helpful in sectors where preserving product purity is crucial, such food manufacturing and medicines.

Their capacity to handle a variety of materials, from liquids and gases to granular and powdered solids, is another significant advantage. Because of their adaptability, these valves can be used in a wide range of settings, such as pneumatic conveying systems, mining activities, and chemical processes. Additionally, the inflatable seat design decreases friction, which lessens component wear and tear and increases valve lifespan.

These valves also have a positive shutdown feature, which enables them to entirely stop the material flow when needed. In circumstances when precise flow control is necessary, this is crucial. These valves are also simpler to use than other kinds due to their reduced torque, which lowers the effort required to open and close the valve and increases operational efficiency.

These valves may be used in tough locations because of their strong structure, which enables it to endure extreme temperatures and hostile chemicals. Ultimately, inflatable seat butterfly valves save a lot of money over time because of their effective design, which also means that they require less maintenance. Because of all these advantages, inflatable seat butterfly valves are a dependable and affordable option for flow control in a variety of applications.

The benefits of utilizing inflatable seat butterfly valves as opposed to conventional ones are discussed.

In many industries, inflatable seat butterfly valves are the favored option due to their numerous advantages over conventional ones. Their strong sealing ability is one of the main advantages. Leakage is prevented by the inflatable seat, which guarantees a tight seal. This is because traditional valves can be difficult to use. This function guarantees safety in addition to improving operating efficiency—especially while handling potentially dangerous materials. Furthermore, these valves are appropriate for sectors handling corrosive or abrasive chemicals because they are made to withstand hostile environments. Long term cost benefits are achieved by reducing maintenance requirements due to their resistance to wear and tear. Additionally, inflatable seat butterfly valves provide improved flow control, making it possible to precisely regulate the flow rate—a critical component in many operations. Their capacity to adjust to low differential pressures, which makes them appropriate for a broader range of applications, is another significant benefit. When compared to conventional valves, inflatable seat butterfly valves are a more dependable and effective option because of these characteristics.

How various applications benefit from the distinctive design elements.

Valves' distinctive design features greatly improve the value of a wide range of applications in numerous sectors. For example, in high-pressure and high-temperature settings like power plants, the robustness and endurance of metal-seated ball valves are essential for maintaining continuous operations and lowering maintenance costs. In the automobile industry, the versatility of flow-mode MR valves—which employ smart fluids for precise control—is essential for improving vehicle performance and safety. The capacity of particular valves to manage the special characteristics of geothermal energy helps to produce energy in geothermal power plants more efficiently. The function of valves in stormwater systems to reduce flood risk highlights their significance for environmental sustainability and provides an affordable flood control solution. Valve treatments such as Gaucher's disease show promise in terms of bettering patient outcomes and quality of life in the healthcare industry. Therefore, valves' distinctive design elements benefit economy, safety, the environment, and public health in addition to increasing functionality and efficiency.

Factors to Take Into Account When Selecting Inflatable Seat Butterfly Valves

Many factors must be taken into account when selecting inflatable seat butterfly valves to make sure they satisfy the demands of the particular application. The first and most important consideration is the kind of media that the valve will regulate. This can include gases, liquids, semi-solids, and even dry materials. Each of these could have a unique flow characteristic and call for a distinct kind of valve. For example, the valve needs to be constructed from materials that can survive abrasive or corrosive media.

Second, the operational environment is a crucial factor to take into account. This includes elements like pressure and temperature, which have a big impact on how well the valve works and how long it lasts. For instance, the valve should be made to withstand high temperatures without losing its functionality if it is required to perform under such situations.

The needed flow rate is the third factor to take into account. Various applications could call for various flow rates, and the valve that is selected should be able to meet these requirements. It's crucial to take into account if the valve will be utilized for on-off control only or for throttling.

Fourthly, installation and maintenance simplicity should be taken into account. Simple to install and maintain valves can save a lot of money by minimizing downtime and related expenses. The accessibility of replacement parts and professional assistance is also crucial.

Lastly, price is an unavoidable factor. Although quality should never be compromised, the valve of choice should be reasonably priced. This covers both the original purchase price and ongoing expenses like upkeep and energy use.

In summary, selecting the appropriate inflatable seat butterfly valve necessitates a careful analysis of the application needs and operating environment, as well as a fair evaluation of quality, price, and support services.

Things to take into account while selecting inflatable seat butterfly valves for certain uses.

Inflatable seat butterfly valve selection for certain applications requires taking into account a number of parameters. First and foremost, the type of material being handled is important. The physical and chemical characteristics of the substance, such as its viscosity, corrosiveness, or granular nature, should be compatible with the valve. Second, because they can impact the valve's longevity and function, the operating conditions—including temperature and pressure—must be considered. Thirdly, it matters how much sealing is necessary. When absolute zero leakage is required, like in the food or pharmaceutical industries, an inflatable seat butterfly valve with superior sealing qualities would be a good option. The simplicity of use and upkeep should be taken into account fourth. Reduced downtime and increased operational efficiency are two benefits of using valves that require less force to operate and less frequent maintenance. Finally, cost-effectiveness is an essential component. Some high-quality valves may require a large initial investment, but over time, they may prove to be more cost-effective due to reduced maintenance and operating expenses. Therefore, choosing the best inflatable seat butterfly valve can be guided by comprehending the particular needs of an application and evaluating these criteria.

Quality control and upkeep are essential for optimum performance.

It is impossible to exaggerate the significance of quality and upkeep for maximum functionality. Superior machinery and equipment are built to last and carry out their intended tasks with efficiency and dependability, which greatly increases an operation's total productivity and profitability. However, proper maintenance is necessary for these assets to continue performing at their current levels. For machinery to continue operating at its best, regular maintenance is essential. It assists in the early identification of possible problems, enabling prompt repairs and averting expensive malfunctions. Moreover, upkeep tasks like cleaning, lubrication, and calibration contribute to an equipment's longer lifespan and ultimately lower costs. Thus, maintaining optimal performance, reducing downtime, and optimizing return on investment require investing in high-quality equipment and following a regular maintenance program.

Conclusion

In summary, inflatable butterfly valves provide a unique approach to flow control that sets them apart from the competition. They are an effective and flexible option for a variety of sectors because of their distinctive design qualities, which include strong construction, little friction, positive shutoff, excellent sealing capabilities, and adaptation to different materials.

The inflatable seat's remarkable sealing capacity guarantees complete sealing, an essential feature in businesses where product purity is a non-negotiable. These valves have a wider range of uses since they can handle a variety of materials, including granular materials, liquids, and gases. This makes them beneficial in mining, chemical processing, and pneumatic conveying systems, among other applications.

Furthermore, the reduced friction design prolongs the valve's lifespan and lessens component wear and tear, which ultimately saves a substantial amount of money. Exact flow management is made possible by the positive shutdown feature, which boosts operational efficiency even further. These valves' sturdy design also makes it possible for them to resist adverse circumstances, which increases their dependability and longevity.

Although conventional valves are still useful, it's obvious that inflatable seat butterfly valves have a number of benefits that make them unbeatable. They offer superior flow control, require less upkeep, and are more resilient to abrasion. Because of these advantages, they are an affordable solution that enhances several applications.

Inflatable seat butterfly valves mark a major advancement in the realm of flow control as we continue to investigate and develop it. Their distinctive design and wide range of uses highlight how crucial ongoing innovation is to this sector. Through the integration of these sophisticated valves into their operations, businesses may boost productivity, save expenses, and ultimately propel their success.