Fireproof and anti-static ball valves are mainly used in gas pipelines with flammable and explosive media, such as natural gas, liquefied petroleum gas and their mixtures. Common ball valves are used for non-flammable and explosive pipelines, such as water, air, etc. The main difference between them lies in their internal structure, which cannot be distinguished by their appearance. The appearance of the anti-static ball valve is marked as AS. The symbol of fireproof ball valve is FD.

Fire prevention is divided into three parts: fire prevention at the ball core and valve seat (B), fire prevention at the flange in the valve body (C), and fire prevention at the valve stem (A).

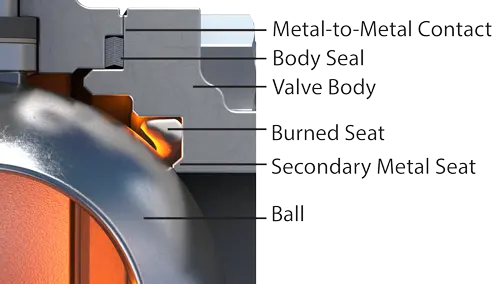

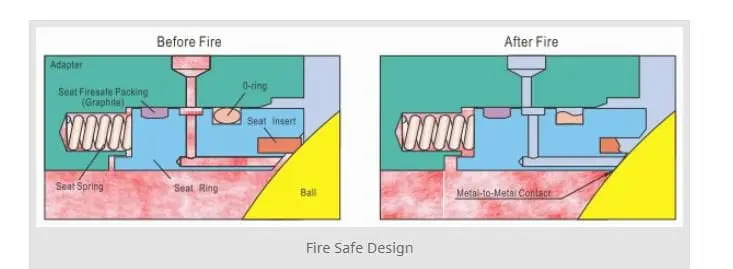

Fire resistance at the ball core and valve seat. When a fire occurs, the soft sealed ball valve is a structure that can maintain a certain sealing performance even after the valve seat is burned out by high temperature. That is to minimize the occurrence of internal leakage as much as possible. Although hard sealed ball valves can avoid the burning of soft sealed ball valve seats in case of fire, it is difficult for hard sealed ball valves to achieve the sealing performance of soft sealed ball valves during normal operation. There may be a small amount of internal leakage, especially in gas pipelines. Soft sealed ball valves are more widely used.

For internal leakage prevention, the upstream pressure will push the ball to downstream metal seat to cut off medium and prevent the internal leakage when the soft seat is destroyed because of the fire. In addition, a fireproof packing of graphite at the metal seat ring can also prevent internal leakage.

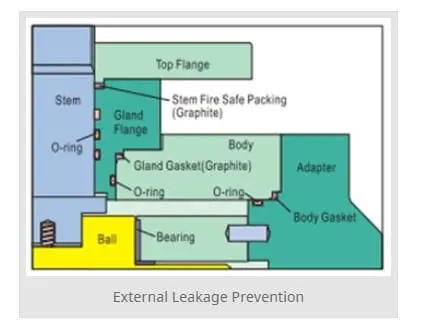

For external leakage prevention, there will be two layers of sealing at all the possible external leakage points between stem & gland flange, gland flange & body, and body & adapter, one is O-ring, and the other is graphite gasket. The secondary graphite gasket will prevent external leakage when the O-ring sealing is burnt.

Generally speaking, the fire testing of ball valve is carried out as per API 6FA, API 607, ISO 10497 or BS 6755 Part II.

The soft sealed seat of the fireproof ball valve is embedded in the groove of the valve body. During normal operation, the seat of soft sealed valve remains sealed. When it burns out, the ball core is pushed by the medium pressure to maintain a hard sealing state near the metal sealing surface of the inner ring, reducing internal leakage. The valve seat of an common ball valve is directly installed between the valve body and the ball core. After it is burned out, it cannot effectively form a metal hard seal.

The flange in the ball valve is fireproof. The ball valve body is a two-piece or three-piece split structure and it is assembled by bolts. There are O-ring seals and graphite metal wound gaskets between each section of the valve body to maintain sealing. After the O-ring is burned out during a fire, the graphite metal wound gasket still maintains the valve body without leakage or a small amount of leakage. There is also a metal contact seal between the valve bodies. For a one piece structure ball valve, the valve body is an integral type, and the valve body is basically leak proof.

Fire protection at the valve stem. It refers to the sealing packing of the valve stem. PTFE is melted at high temperature, and the pressure inside the valve body will push the valve stem out of the valve body. The shoulder on the valve stem is blocked by the valve body. Use the pressure inside the valve body to compress the valve stem tightly, forming a seal. This lower mounted valve stem can also prevent the valve stem from being pushed out of the valve body by medium pressure when the cavity of the ball valve is abnormally pressurized, ensuring safety. Fillers can use high-temperature resistant flexible graphite fillers, graphite metal wire combination pressing and other special fillers.

Anti static structure. According to the national standard GB/T12237, for a ball valve with diameter less than DN50, the valve stem and valve body can conduct electricity. For ball valves with a diameter greater than DN50, it is necessary to ensure conductivity between the ball core, valve stem, and valve body. When the power supply voltage does not exceed 12V, the anti-static resistance between the ball core, valve stem, and valve body is less than 10 Ω.

The conductive structure involves drilling small holes in two positions on the valve stem, one in contact with the valve body and the other in contact with the ball core. Install springs and small metal balls in the small holes. The small metal ball is lifted by the spring to ensure contact with the valve body, valve stem, and ball core, forming a conductive circuit.

The valve stem of common ball valves does not have an electrostatic conductive structure. Common ball valves cannot replace fire-resistant and anti-static ball valves. Firstly, they do not have anti-static function, and secondly, they do not have a fire-resistant structure. Therefore, there is a possibility of fire.