There are various types of valves used in pneumatic conveying systems, including dome, cone, plate, flap, and others. Of these, the dome valve is the most commonly utilized in a variety of industries due to its straightforward construction, ease of use, and reliable performance. It requires little upkeep and is quite effective. So, let’s go deep into this dome valve tutorial with its operating concept and perks.

What is a Dome Valve?

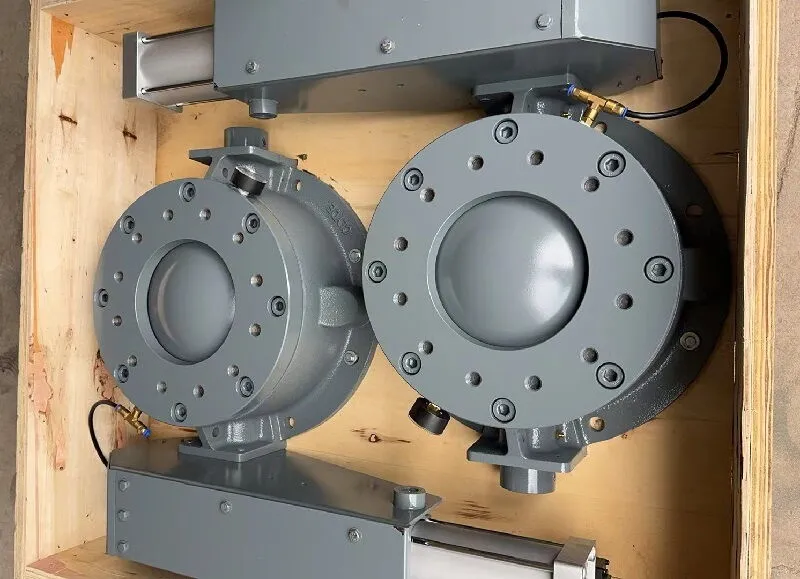

In pneumatic conveying systems, abrasive or abrasive-containing materials are handled by dome valves, a particular kind of valve. It is frequently utilized in sectors including chemical processing, mining, power generation, and cement manufacturing where handling abrasive materials presents difficulties for conventional valves. Dome valves are distinguished by their special dome-shaped sealing element, which keeps material buildup and obstructions at bay while separating the process material from the valve mechanism. When the dome valve is opened and closed, the dome valve seal automatically deflates to prevent contact with the medium. In order to prevent needless wear, the silicon rubber seal automatically inflates only when the dome is entirely closed. There are three types of rubber seat materials: silicon rubber, viton, and EPDM.

The characteristics and workings of dome valves are as follows:

1.Features:

- Dome-shaped sealing element: The unique dome-shaped seal acts as a self-cleaning mechanism while the valve is in use, preventing material accumulation and guaranteeing dependable sealing even under harsh operating circumstances.

- Abrasion-resistant construction: To resist the eroding effects of abrasive materials, dome valves are built using materials such hardened steel, ceramic, or abrasion-resistant coatings.

- Full bore design: Dome valves normally feature an opening that is fully sized, enabling materials to pass through the valve without obstruction or dead zones.

- Dome valves have a quick-acting mechanism that allows for speedy opening and closing to reduce material leakage and preserve process efficiency.

- Minimal maintenance needs: Dome valves are appropriate for continuous operation in tough industrial situations because of their sturdy construction and self-cleaning design.

- The movement of a dome-shaped sealing element regulates the material flow via the valve body in the basic working principle of a dome valve.

- When the valve is closed, the dome seal presses firmly on the valve seat to stop material from passing through the valve.

- Material can pass through the whole bore opening of the valve body when the valve is actuated to open because the dome seal lifts from the valve seat.

- The dome seal acts as a self-cleaning mechanism as the material passes through the valve, avoiding obstructions or material accumulation that can reduce the function of the valve.

- The dome seal returns to its seated position when the valve is activated to close, creating a tight seal against the valve seat to stop the flow of material.