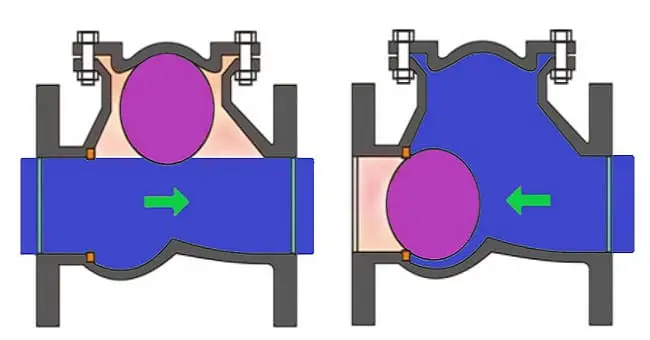

A ball check valve is a type of valve that allows fluid to flow in only one direction. It consists of a ball-shaped disc that is positioned in a passageway, with a spring pushing the ball against the valve seat.

When fluid flows in the desired direction, the ball is pushed away from the seat, allowing the fluid to

pass through. However, if the flow reverses, the ball is forced back into the seat, preventing the fluid from

flowing backwards. Ball check valves are commonly used in applications where backflow prevention is important,

such as in plumbing and irrigation systems.

When would u use a ball check valve

A ball check valve is typically used in applications where there is a need to prevent backflow or reverse flow of fluids or gases.

This type of valve is designed with a ball that sits inside the valve body and allows fluid or gas to flow in only one direction.

Ball check valves are commonly used in plumbing systems, water treatment plants, and in the oil and gas industry.

They are also used in applications where there is a need to prevent contamination of fluids or gases, such as in food processing or

pharmaceutical manufacturing.

Overall, the use of a ball check valve would depend on the specific application and the requirements of the system.

What is the advantage of Ball check valve

A ball check valve has several advantages over other types of check valves. One of the main advantages is that it has a simple design,

which makes it easy to install and maintain. Additionally, because the valve is made up of a ball and a seat, it is very effective at preventing

backflow and leakage. The ball rotates freely within the valve, allowing it to seal tightly against the seat and prevent any media from

flowing backwards. This makes it an excellent choice for applications where backflow prevention is critical, such as in water treatment systems,

pump discharge lines, and other industrial processes. Another advantage of ball check valves is that they are available in a wide range of materials,

including metals, plastics, and ceramics, making them suitable for use in a variety of different environments and applications.

What is the difference between ball valve and ball check valve

A ball valve and a ball check valve are two different types of valves that serve different purposes.

A ball valve is a type of valve that uses a ball to control the flow of a liquid or gas. The ball has a hole through the center that

allows the liquid or gas to flow through when the valve is open. When the valve is closed, the ball is rotated so that the hole is

perpendicular to the flow of the liquid or gas, blocking the flow.

On the other hand, a ball check valve is a type of valve that uses a ball to prevent backflow in a pipeline. The ball is held in place by

a spring or gravity, and when the pressure on the upstream side of the valve is greater than the pressure on the downstream side, the ball is

pushed against the valve seat, preventing backflow. When the pressure on the downstream side is greater than the pressure

on the upstream side, the ball is pushed away from the valve seat, allowing flow.

So, while both valves use a ball to control flow, a ball valve is used to control flow in a pipeline, while a ball check valve is used to prevent backflow.

How to install a ball check valve

Installing a ball check valve can be a bit tricky, but with the right tools and steps, it can be done easily. Here are some general steps to follow:

1. Choose the right valve: Make sure you have the correct size and type of valve for your application.

2. Turn off the water supply: Before installing the valve, turn off the water supply to avoid any water flow.

3. Prepare the pipe: Clean the pipe ends and remove any burrs or debris that may interfere with the valve's installation.

4. Install the valve: Insert the valve into the pipe, making sure that the arrow on the valve body is pointing in the correct direction of flow.

Tighten the valve's compression nuts onto the pipe ends.

5. Test the valve: Turn on the water supply and check for any leaks or malfunctions.

6. Secure the valve: Once you have confirmed that the valve is functioning properly, secure it in place with brackets or straps.

Remember to always follow the manufacturer's instructions and consult a professional if you are unsure about the installation process.