A top entry ball valve is a type of valve that is designed with its entry point at the top of the valve body. It is commonly used in industries such as oil and gas, chemical, and petrochemical, where high-pressure and high-temperature applications are prevalent.

The distinguishing feature of a top entry ball valve is that it allows for easy access to the valve internals for maintenance or repair without the need to remove the entire valve from the pipeline. This is particularly advantageous in situations where the valve is installed in a large pipeline or in areas with limited space.

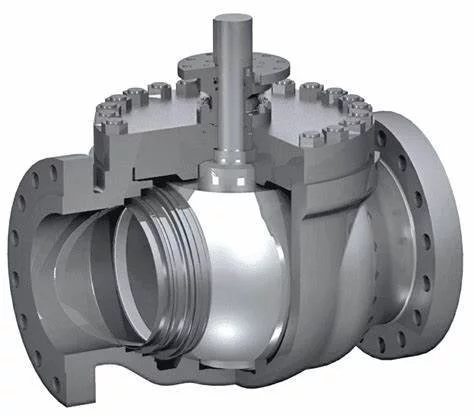

The ball inside the valve is typically made of metal and has a hole through it. When the valve is in the open position, the hole aligns with the flow path, allowing fluid or gas to pass through. When the valve is closed, the ball is rotated so that the hole is perpendicular to the flow path, effectively blocking the flow.

Top entry ball valves are known for their durability, reliability, and ability to handle high pressures and temperatures. They are often used in critical applications where tight shut-off is required, such as in pipelines, refineries, and power plants.

How Does A Top Entry Ball Valve Work?

The basic working principle of a top entry ball valve is as follows:

1. In the closed position: When the valve is closed, the ball is rotated so that the hole in the ball is perpendicular to the flow direction. This blocks the flow of fluid, preventing it from passing through the valve.

2. In the open position: When the valve is opened, the ball is rotated 90 degrees so that the hole in the ball aligns with the flow direction. This creates a straight path for the fluid to pass through the valve, allowing it to flow freely.

The rotation of the ball is controlled by the valve handle or actuator. When the handle or actuator is turned, it rotates the ball, changing its position and thus controlling the flow of fluid.

Types of Top Entry Ball Valve

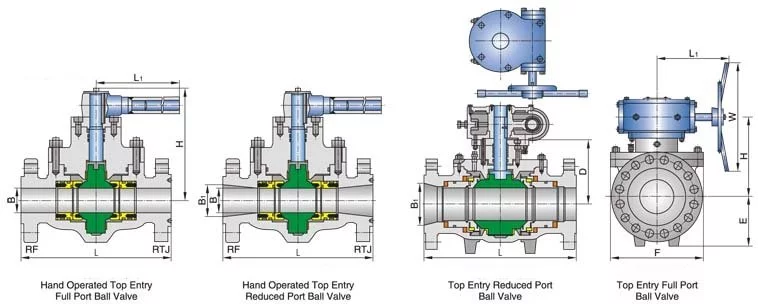

There are several types of top entry ball valves based on their construction and application:

1. Full bore top entry ball valve: This type of valve has a full bore opening, which means the ball and seat have the same diameter as the pipeline. It offers minimal flow restriction and is suitable for applications where low pressure drop and high flow rates are required.

2. Reduced bore top entry ball valve: In contrast to the full bore valve, the reduced bore top entry ball valve has a smaller ball and seat diameter than the pipeline. This design can result in a higher pressure drop but is often used in applications where cost and space constraints are a consideration.

3. Trunnion-mounted top entry ball valve: Trunnion-mounted ball valves have additional support from trunnions, which are shafts that extend through the ball. This design provides increased stability and is commonly used in high-pressure and large-diameter applications.

4. Floating ball top entry ball valve: In a floating ball valve, the ball is not fixed and is free to move. The sealing is achieved by the pressure of the fluid against the ball. This type of valve is suitable for lower-pressure applications.

5. Metal seated top entry ball valve: Metal seated ball valves use metal-to-metal sealing between the ball and seat. They are suitable for high-temperature and abrasive fluid applications where resilient or soft-seated valves may not be able to withstand the conditions.

These are just a few examples of the types of top entry ball valves available. The specific type of valve you choose will depend on factors such as the application, pressure, temperature, and the type of fluid being handled.

What Are The Benefits and Features of Top Entry Ball Valve?

Top entry ball valves have several benefits and features that make them popular in various industries. Here are some key advantages:

1. Easy Maintenance: One of the significant advantages of top entry ball valves is their ease of maintenance. These valves can be serviced without removing them from the pipeline, as their top entry design allows for quick access to internal components. This saves time and reduces operational downtime.

2. Durability and Reliability: Top entry ball valves are known for their robust construction, making them highly durable and reliable. The design typically incorporates sturdy materials such as stainless steel, which can withstand high pressures and temperatures, as well as corrosive environments.

3. Enhanced Sealing: These valves provide excellent sealing capabilities due to their floating ball design. The ball is held against the seat by the pressure of the fluid, creating a tight seal that prevents leakage. This feature is particularly important in applications where leakage can lead to significant consequences or safety hazards.

4. Bi-Directional Flow: Top entry ball valves offer bi-directional flow control, meaning they work equally well in either direction. This feature provides flexibility in installation and allows for smooth operation, regardless of the flow direction.

5. Full Bore Design: Many top entry ball valves come with a full bore design, which means the internal diameter is the same as the pipeline. This feature minimizes flow restrictions and pressure drop, ensuring efficient fluid passage with minimal energy loss.

6. Wide Range of Applications: Top entry ball valves find applications in various industries, including oil and gas, chemical processing, power generation, and water treatment. They are suitable for both onshore and offshore installations and can handle a wide range of fluids, including gases and liquids.

7. Versatile Operation: These valves offer versatile operation options, including manual, pneumatic, and electric actuation. This flexibility allows for seamless integration into different control systems and enables remote or automated operation when required.

Remember, the specific benefits and features of top entry ball valves may vary based on the manufacturer, design, and intended application. It's always recommended to consult the product specifications and consult with experts before selecting a valve for a particular use case.

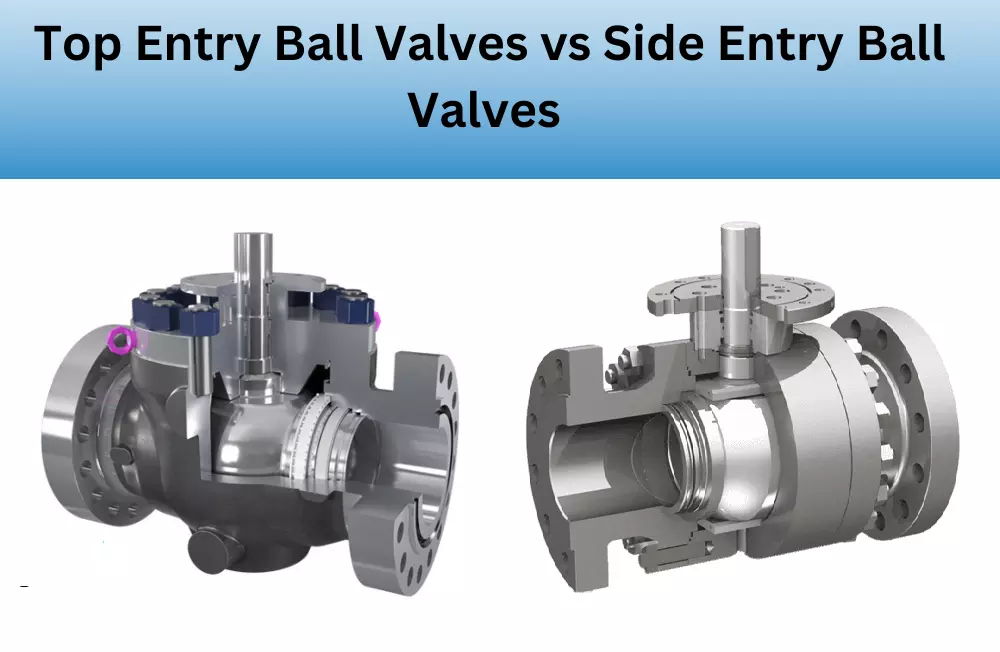

Top Entry Ball Valve Compared With Side Entry Ball Valve.

When comparing top entry ball valves and side entry ball valves, there are a few key differences to consider.

Firstly, the entry point of the fluid flow is the main distinction between the two. In a top entry ball valve, the fluid enters and exits through the top of the valve body, while in a side entry ball valve, the fluid enters and exits from the side of the valve body.

One advantage of top entry ball valves is that they allow for easier maintenance and repair. With the top entry design, you can access the internals of the valve without removing it from the pipeline. This makes it more convenient for inspection, cleaning, or replacing parts.

On the other hand, side entry ball valves are often preferred in applications where space is limited. Since the fluid flows in and out from the side, these valves can be more compact and require less vertical clearance. They are commonly used in pipelines with tight installations or when there are height restrictions.

Another consideration is the pressure rating. Top entry ball valves tend to have higher pressure ratings compared to side entry ball valves. This makes them suitable for high-pressure applications where maintaining the integrity of the valve under extreme conditions is crucial.

Ultimately, the choice between a top entry ball valve and a side entry ball valve depends on the specific requirements of your application, such as available space, pressure rating, maintenance needs, and installation constraints. It's best to consult with a valve specialist or engineer to determine which type would be most suitable for your particular situation.

Summary:

Top Entry Ball Valves are mainly used where there is frequent maintenance is required for the valve and the seat, it provides ease of access for maintenance and repairs as the ball and the seat inside the valve can be maintained from the top of the valve and without dismantling the whole valve from the pipeline.