A check valve composed of aluminum bronze is a robust and resistant to corrosion alloy composed of copper, aluminum, and occasionally other metals. This kind of valve is frequently utilized in situations involving corrosive fluids, extreme temperatures, or pressures. Here is more information about check valves made of aluminum bronze.

Check valves made of aluminum bronze provide a lot of benefits that make them a good option for situations where minimal upkeep and affordable prices are required.

In order to avoid backflow and any harm to the environment or equipment, they are made to only permit fluid to flow in one direction. Let's examine the valve in more detail.

What is Aluminum Bronze Check Valve?

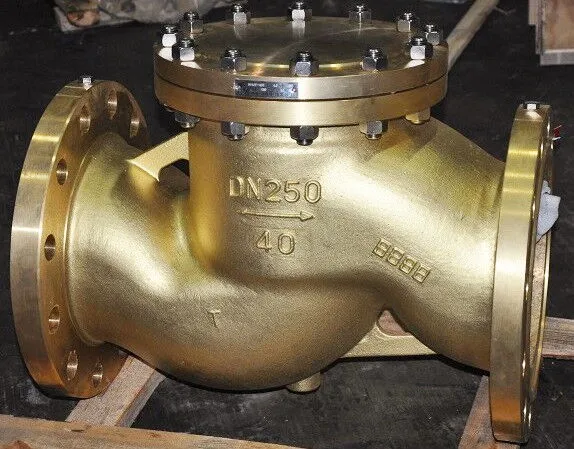

One kind of valve used to regulate fluid flow in a pipeline is an aluminum bronze check valve. Aluminum bronze, a copper and aluminum alloy with exceptional resistance to erosion and corrosion, is used to make it. The valve is made to exclusively permit one direction of fluid flow, preventing backflow and shielding pipes and equipment from harm. Check valves made of aluminum bronze are frequently utilized in environments with high temperatures, high pressures, or corrosive fluids, including the chemical, petrochemical, and maritime sectors.

Types of Aluminum Bronze Check Valves

1. FlangedPipelines and other fluid handling systems frequently use flanged aluminum bronze check valves to control fluid flow. These check valves, which come in a variety of sizes and styles, offer efficient fluid control options.

This kind of valve has a center-guided, spring-assisted design with a disc that slides along the valve seat's centerline to provide dependable shutdown and the ability to control or throttle flow.

2. Threaded

All sectors use threaded aluminum bronze check valves, but steam and petrochemical applications use them more than others. Because of their durable design, they can survive the high pressure and harsh conditions present in these applications.

They're also perfect for high-temperature, long-cycle opening and closing gas and oil production applications like refining or gas extraction.

3. Threaded Body

Made of premium materials, threaded body aluminum bronze check valves are an affordable and practical solution to backflow issues. They are ideal for use in oil and gas generation, commercial construction, fire safety, HVAC, irrigation, mining, water and waste treatment systems, and irrigation.

4. Threaded Stem

There are many applications for threaded stem aluminum bronze check valves, including wastewater management, food processing facilities, power plants, oil and gas pipelines, water lines, and saltwater pollution control. They are affordable options due to their small size.

This valve functions as a spring-loaded silent check valve, shutdown valve, and balancing valve in pump discharge piping applications. It has a bronze body and trim, a flanged connection, and a bolted cap.

Applications of aluminum bronze check valve

Check valves made of aluminum bronze are widely employed in a variety of industries due to their exceptional strength, longevity, and resistance to corrosion. The following are some common uses for aluminum bronze check valves:Chemical synthesis

maritime use

Oil and gas industry Mining industry

Energy production

Water purification

Working principles of aluminum bronze check valve

Check valves made of aluminum bronze are made to only permit one direction of fluid flow, preventing backflow and safeguarding downstream machinery.

Usually composed of aluminum bronze, the valve body has a high strength and resistance to corrosion.

A spring holds the hinged disc or ball of the valve in place. The disc or ball is forced open to let the fluid pass through when it flows in the intended direction.

The fluid's pressure forces the disc or ball shut, stopping backflow, even if the fluid tries to flow in the opposite direction.

Check valves made of aluminum bronze can be made to operate in a range of flow circumstances, such as high and low temperatures, high and low pressures, and high and low flow rates.

For maintenance or testing purposes, a lever or handle on certain aluminum bronze check valves can be used to manually open or close the valve.

Advantages and Features of Aluminum Bronze Check Valves

Check valves made of aluminum bronze are highly prized alloys because of their remarkable toughness, strength, and resistance to corrosion. These characteristics make aluminum bronze valves ideal for desalination projects and any other scenario requiring a long-lasting, hard-wearing valve. They also boast low rates of atmospheric corrosion, low rates of high-temperature oxidation, and inertness with sulfurous compounds from combustion products or any sulfur-containing gases present.

- Durability

These valves' sliding valve disc, which modifies the valve seat port, also contributes to their exceptional flow management and shutdown capabilities.

- Corrosion Resistance

These pumps are a great option for usage in the oil and natural gas industry, chemical plants, and maritime facilities since they can withstand strong chemicals and acids without breaking down.

They are also helpful in cryogenic environments and can tolerate high pressures and temperatures without rupturing or cracking, which is a vital asset in several applications.

- Lifespan

- Cost

These valves come in a variety of body and bonnet materials with multiple trim options, and they are intended to permit one-way flow while preventing reverse flow in pipe systems.

Torsion springs that seal the valve prior to flow reversal and downstream stop shafts that stabilize discs under high pressure are two other features that make maintenance easier on these valves.

Offering gate, globe, ball, check, strainer, and plug valves in carbon steel, stainless steel, duplex stainless steel, and alloy materials, JONLOO Valve is a market leader in the industrial valve business. These valves can be customized to satisfy certain demands, such as those related to pressure drops, temperatures, flow rates, and pressures. Furthermore, its corrosion-resistant design simplifies maintenance and cleaning.