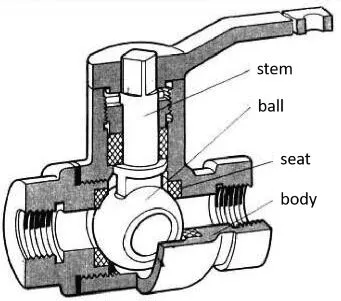

A ceramic ball valve is a kind of ball valve with ceramic-based internal components. These ceramic parts include the lining, seat, and ball. The body of a ceramic ball valve is composed of a metallic substance, like carbon steel or stainless steel. The ceramic trim is shielded from harm by the metallic body from unexpected mechanical or thermal shock. When the handle of a ceramic ball valve is cranked, fluid flows through a ball having a hole in the middle. Actuators such as hydraulic, electric, or pneumatic actuators can also be used to automate ceramic ball valves. Ceramic ball valves provide superior wear resistance and reduced mass compared to other materials like steel. Ceramic ball valves have superior wear and corrosion resistance. Ceramic ball valves with these qualities are employed in harsh environments where corrosion and abrasion are common. Numerous industries, including manufacturing facilities, chemical engineering, and petroleum, use ceramic ball valves.

Figure: Ceramic ball valve.

In order to open or close a manually controlled ceramic ball valve, the operator must apply torque to the handle. In actuated ceramic ball valves, the actuator supplies the necessary torque to open or close the valve in addition to the automation intelligence.

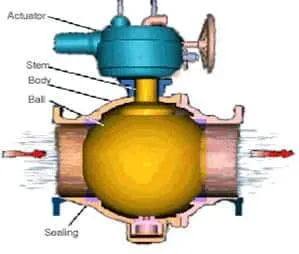

All of the internal components of the ceramic ball valve are housed in this component. Strong metallic elements like carbon steel and stainless steel are used to make the valve body. This gives the valve a high mechanical strength that allows it to resist impact damage and high pressure. The ceramic ball valve's inlet and outlet ports are located within the valve body.

This is the part of a ceramic ball valve that transfers torque to the ball from the handle or actuator. The ball and actuator/handle are connected by the stem.

The function of the ball in a ceramic ball valve is to open and close fluid flow. The stem connects the ball to the handle or actuator. When the valve is open, fluid passes through the bore in the middle of the ball.

To support the ball and stop fluid leaks, these parts are positioned between the valve body and the ball.

Trim describes the interior parts of the ceramic ball valve, such as the seats, O-rings, and glands, that come into touch with the fluid.

This part of the ceramic ball valve improves the fluid-tight seal around the handle and stem assembly by creating a seal between the stem and the valve body.

Figure: Components of a ceramic ball valve.

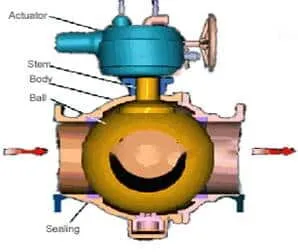

Applications for ceramic ball valves include on/off fluid flow. Using a ball with a bore in the middle of it improves a ceramic ball valve's capacity to open and close fluid flow. The valve stem connects the ball to the actuator or valve handle. The fluid flow through the valve is closed and opened by the ball. Via the ball bore, the fluid passes through the ceramic ball valve. A ceramic ball valve is started by rotating its handle 90 degrees counterclockwise (for manual ceramic ball valves). As a result, the ball and valve stem rotate at the same 90-degree angle. The ball bore aligns with the pipeline when the ball is turned to that 90-degree angle. The ceramic ball valve is considered to be in an open state when fluid flows through it as a result. When the handle of the ceramic ball valve is cranked clockwise, the ball bore rotates and becomes perpendicular to the pipeline, obstructing the passage of fluid. Ceramic ball valves that are operated by an actuator use the same operating principle. The sole distinction is that the manual ceramic ball valve receives its torque from the valve operator, whereas the actuated ball valve receives its torque from an actuator.

Figure: Working of a ceramic ball valve; open valve (left side) and closed valve (right side).

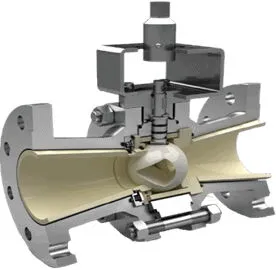

This ceramic ball valve is composed of two body sections that are joined together. The internal components and the other end connection are found in the other piece, whereas the ball and one end connection are found in the first piece. Among ceramic ball valves, the two-piece kind is highly prevalent. It is possible to disassemble a two-piece ceramic ball valve for examination, maintenance, and repair. However, before the pipeline was disassembled for cleaning or repairs, a two-piece ceramic ball valve had to be taken out.

The three components of this ceramic ball valve are the valve body, two end pieces, and the valve itself. Bolts and nuts are used to join the ceramic ball valves' three components. The ball, seats, and stem—the three central components of a ceramic ball valve—can be removed while the valve is connected to the pipeline. Without removing the ceramic ball valve from the pipeline, this aids in clearing obstructed solids, replacing gland packing and seating, and polishing ball scratches. Compared to their two-piece equivalents, three-piece ceramic ball valves are significantly more costly.

It's a three-port ceramic ball valve. There are two possible shapes for three-way ceramic balls: T and L. In industries, three-way ceramic ball valves are used to mix or reroute fluid flows. The fluid is diverted using the L-shaped arrangement. An L-shaped ceramic ball valve directs fluid to another pipeline by diverting it from one port into another at an angle of around 90 degrees. Fluid streams can be mixed or diverted using the ceramic ball valve with a T shape. Two fluid streams are combined to create a single fluid stream that passes through the outlet port when the T-shaped three-way ball valve is in use. If necessary, fluid streams can be redirected from one port into two or one of the three ports using a T-shaped ceramic ball valve.

Figure: Three-way ceramic ball valve.

This ceramic ball valve features valve seats or a V-shaped ball bore. By spinning the ball, ceramic ball valves with V-ports aid in accurately controlling the fluid flow rate. It is possible to tune V-port ceramic ball valves to improve linear flow characteristics. Compared to other ball valves, the v-port ball valve has superior fluid flow control. This is because steady fluid flow management is made possible by the little end of the "V" port opening first when the ceramic ball valve is opened. The high fluid velocity of a V-port ceramic ball valve necessitates a robust construction because a weak design could harm a regular ceramic ball valve. When properly built, V-port ceramic ball valves can be utilized to regulate fluid flow.

Figure: V-port ceramic ball valve.

High-performance structural ceramic materials are used in the design and production of ceramic ball valve internal components. The ceramic ball valve's mechanical strength is increased by the use of high-strength metallic materials in the construction of its body and external components.

Ceramic ball valves have a strong metallic body and are resistant to corrosion and abrasion. A ceramic ball valve's service life is two to four times longer than that of conventional corrosion and abrasion-resistant valves under the same operating conditions.

Ceramic ball valves are effective at preventing corrosion because of their stable chemical properties for the majority of acid-based fluids.

As the name implies, ceramic ball valves are composed of ceramic materials, which are renowned for their extreme hardness. Zirconia, one of these ceramic materials, has a high hardness value of about HRA88, making it the second-strongest substance after diamond.

The seat and ball of ceramic ball valves are smooth, and they self-lubricate when they open and close. Because of this, there is less resistance to opening and shutting, requiring less torque to do so.

Ceramic ball valves seal the ball and seat through surface contact. The ball's high accuracy roundness improves the sealing contact and guarantees that it can produce zero leakage in accordance with international requirements.

- Chemical industries for the transportation of fluids, including polymer slurries and acids.

- They are employed in the manufacturing of fertilizer products, including phosphate, amine nitrate, and phosphoric acid.

- pulp and paper industries to regulate the flow of various fluids, including paper fillers and bleaching agents.

- systems for water delivery and drainage.

- Food and beverage industries.

- Pharmaceutical applications.

- Easy to operate.

- They need small torque to open and close.

- They are versatile valves.

- They are very durable.

- Resistant to abrasion.

- Resistant to corrosion.

- Ceramic ball valves can be inspected, cleaned, and repaired.

- These valves are free from leakage.

- They are very strong for applications involving high temperatures and pressures.

- Close as soon as possible to avoid overpressurization and hammering issues.

- Due to their limited durability, the trim parts are prone to damage.

- Not suitable for throttling applications.

- Damaged ball. Replace the ball.

- Damaged seats. Replace the seats.

- The ball is not fully closed. Check the opening or closing settings of the ball.

- Either the ball and the valve body or the sediments between the seat and the ball. Clean the ceramic ball valve's interior, seal any exposed areas, and swap out the seats if needed.

- Foreign materials in the valve. Remove the materials.

- High pressure and or temperature. Ensure the valve is working for the recommended pressure and temperature rating.

- The seats are damaged. Replace the seats.

- Fluid moving at a very high speed or an improperly sized valve. Make that the fluid flow rates and valve match those suggested by the ball valve manufacturer.

- Loose gland cap screw. Tighten the gland screw.

- Damaged stem seal. Replace the stem seal.

A ceramic ball valve is a kind of ball valve with internal ceramic-made seats, lining, and ball components. Sturdy metallic materials like carbon steel and stainless steel make up the exterior. The metallic materials are intended to offer impact resistance and great strength against high temperatures and pressures. A ball having a bore in the middle is used in ceramic ball valves. A ceramic ball valve allows fluid to pass through the ball bore. Ceramic ball valves are controlled by an actuator or by hand. There are several different kinds of ceramic ball valves, such as two-piece, three-piece, three-way, and v-port ceramic ball valves. Ceramic ball valves are used in a variety of industries, such as the chemical, fertilizer, drainage, water supply, food and beverage, and pharmaceutical sectors. Ceramic ball valves have the following benefits: low working torque, resistance to corrosion and abrasion, leak-free operation, durability, adaptability, and repairability.