A steam trap is a device used in steam systems to remove condensate (water) that forms as steam cools and condenses. Steam traps are installed to prevent condensate from accumulating in the system and causing damage or reducing efficiency.

Steam trap valves work by using a mechanism to open when steam is present and close when condensate is present. This allows the condensate to be removed from the system while keeping the steam in the pipes.

If a steam trap is clogged, it can cause a number of problems. The condensate may not be able to be removed from the system, which can cause damage to pipes, valves, and other components. This can also reduce the efficiency of the system, as the condensate can cause the steam to cool and lose pressure. In addition, a clogged steam trap can cause safety issues, as it can lead to overheating and potentially dangerous conditions. It's important to regularly inspect and maintain steam traps to prevent clogging and ensure proper functioning of the system.

There are several types of steam traps used in steam systems, each with its own unique design and function. Here are some of the most common types:

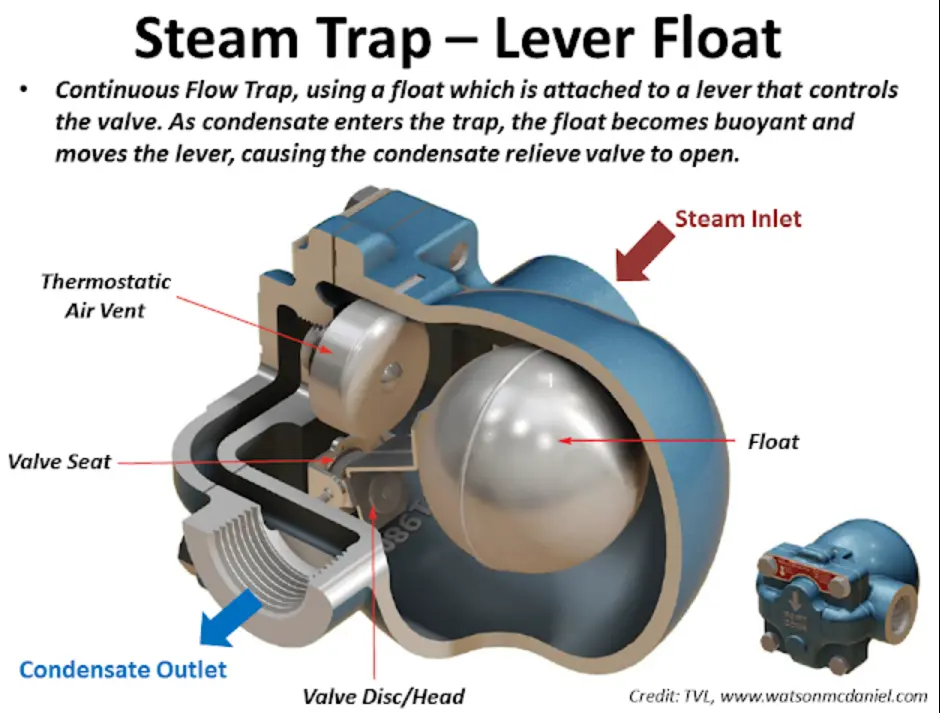

1. Float and thermostatic (F&T) traps: These traps use a float to open and close a valve, and a thermostatic element to modulate the valve's opening. F&T traps are commonly used in steam heating systems.

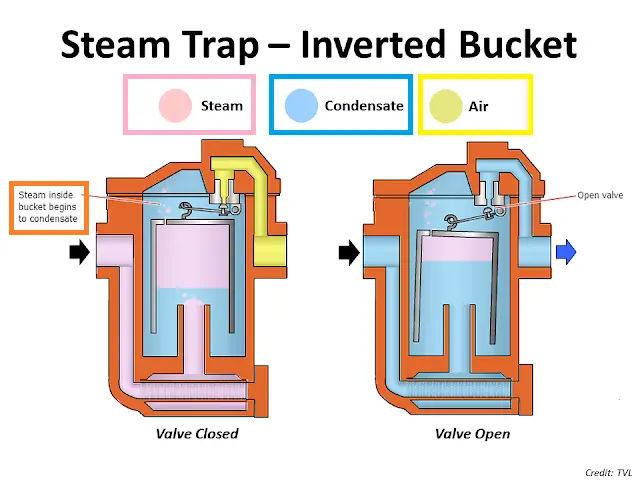

2. Inverted bucket traps: These traps use an inverted bucket to open and close a valve. When steam enters the bucket, it causes the bucket to rise and open the valve. When condensate enters the bucket, it causes the bucket to fall and close the valve.

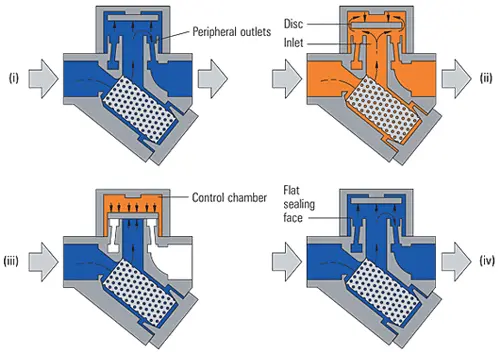

3. Thermodynamic traps: These traps use the difference in pressure between steam and condensate to open and close a valve. When steam enters the trap, it causes a disc to lift and open the valve. When condensate enters the trap, it causes the disc to fall and close the valve.

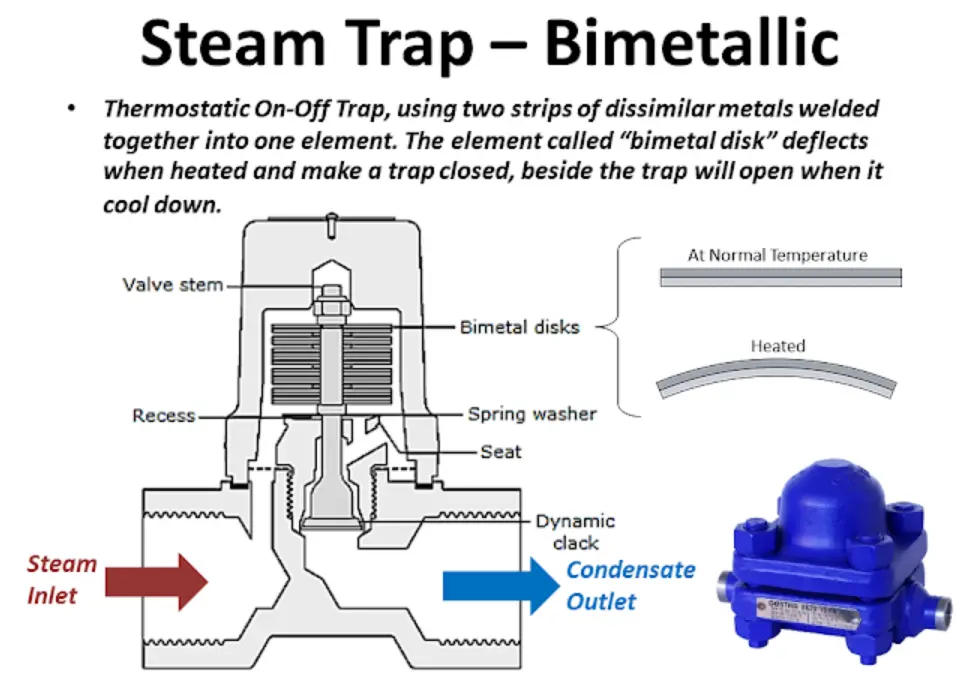

4. Bimetallic traps: These traps use two different metals that expand and contract at different rates when exposed to heat. The resulting movement opens and closes a valve. Bimetallic traps are commonly used in low-pressure steam systems.

5. Disc traps: These traps use a disc that opens and closes a valve based on the difference in pressure between steam and condensate. Disc traps are commonly used in high-pressure steam systems.

These are just a few examples of the many types of steam traps available. The choice of trap will depend on the specific needs of the steam system.