- These valves can handle high temperature and pressure

- The bellow seal can prevent the leakage of sensitive media which could be flammable

- Long life

- It can handle a good amount of steam pressure

Most of the control valves are used for flow and pressure control of process fluid. So the chances of leakage are very high and because of the leakage, there could be loss of material. The material could be radioactive or some kind of chemical and it could lead to many problems in a plant. The fluid which is used could be corrosive, explosive, or poisonous. So in order to solve this problem we can use a bellow seal valve.

We can install a bellow sealed valve in any position, but it should not be installed in a way that the stem is upside down. So we install a bellow seal valve by considering this then we can prevent the accumulation of debris in the bellows area. So before the installation of the bellow valves, we must make sure that the pipes and valves are free from impurities. The pipes must be connected in a way that there won’t be any undue tension acts on to the housing of the valve.

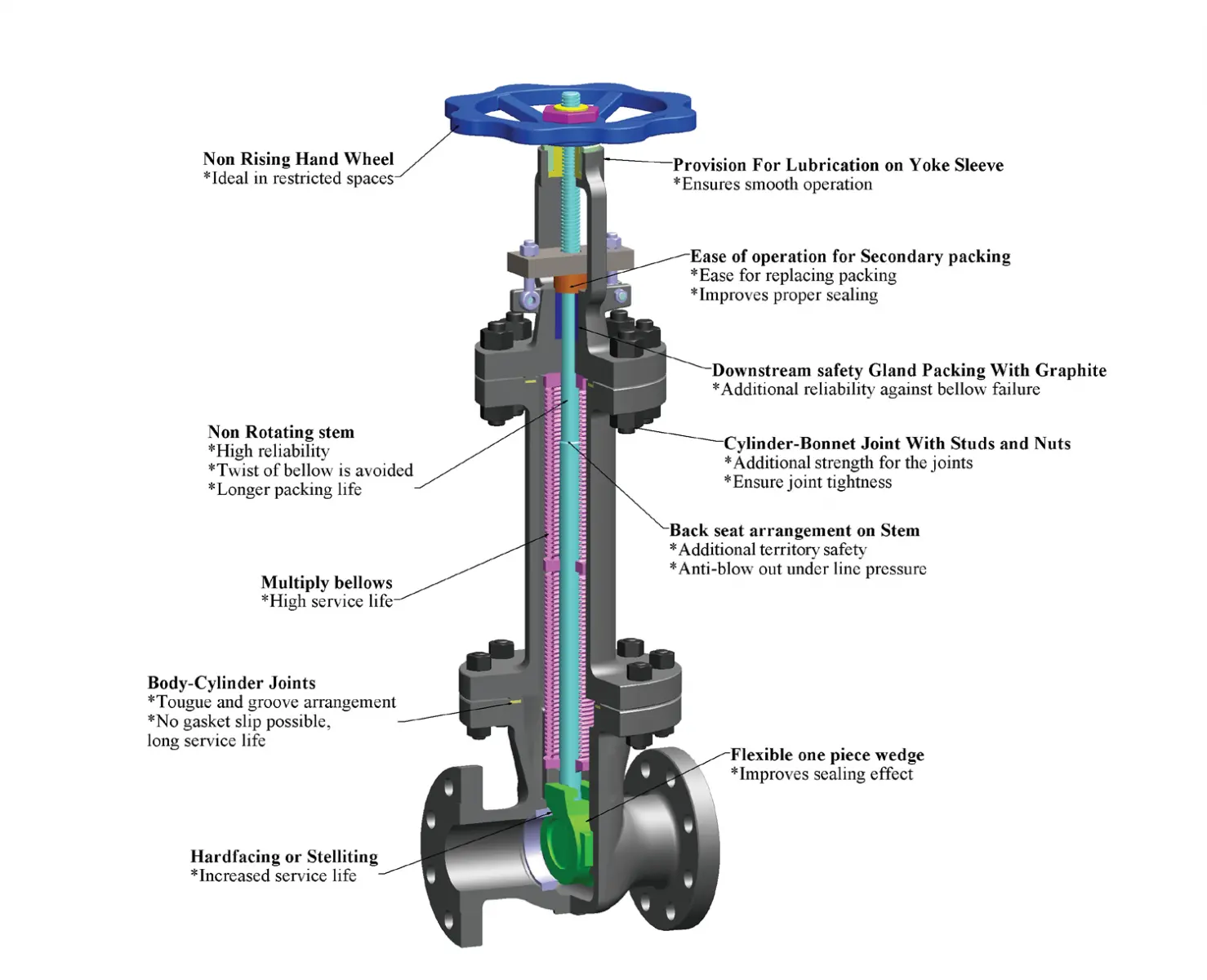

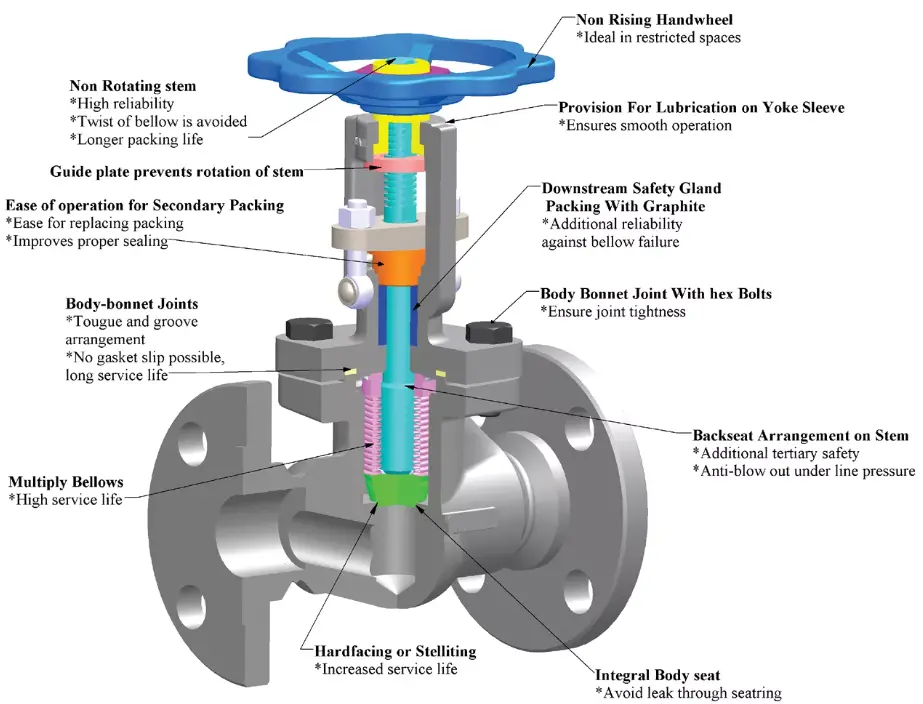

The valve body material must be selected according to the pressure, temperature, corrosive, and erosive property of the flow media. The cartridge of the bellow will be welded, there are many convolutions in a bellow cartridge and these convolutions could be compressed or expanded according to the valve stem movement. The material that is used for the construction of the bellow would be stainless steel and it would also have titanium added to it which would allow the bellow to withstand high temperatures.

A bellow can be considered as a device that is used to transmit axial motion, the bellow is a continuous convoluted tube that can sustain external or internal pressure. The bellow can be sealed to the valve in two different ways, the bellow can be welded to the valve stem at the top and the valve body at the bottom. So in this type, the process fluid will be inside the bellow. The bellow can also be welded to the valve stem at the bottom and the body on the top and in this type, the process fluid will be between the valve bonnet and the bellow.

How is bellow construction?

The bellow cartridge is welded to both the Valve Bonnet and the Valve stem. The bellow cartridge has a number of convolutions and these convolutions become compressed or expanded depending upon the movement of Valve stem. (Scientifically speaking the bellow gets compressed when the Valve is in the open position and expanded when the Valve is in the closed condition). It is important to properly install the Valve bodies. The bellow can be sealed to the Valves in two different ways. Firstly, the bellow can be welded to the Valve stem at the top and the Valve body on the bottom. In this case the process fluid is contained inside the bellow or in second method the bellow is welded to the Valve stem at the bottom and the body on the top. In this case the process fluid is contained in the annular region between the Valve Bonnet and bellow (from the outside).

The bellow is a critical component and forms the heart of the bellow seal Valves. To avoid any twisting of the bellow the Valve must have a stem with linear movement only. This can be achieved using a so-called sleeve-nut at the Yoke portion of the Valve Bonnet. A handwheel is fitted onto the sleeve-nut which effectively transfers a rotary motion of the handwheel into a linear motion in the Valve stem.

The bellow would contract and expand when the valve stem moves up and down, the bellow would get compressed if the valve is in open condition and it will be expanded if the valve is in closed condition. So the bellow is in closed packed with the stem so there won’t be any chance of leakage.

Types of bellows

Forged bellow

This type of bellows is constructed by rolling a flat sheet into a tube, mostly it would be a thin wall foil. This tube will be then welded longitudinally, this tube will be mechanically or hydrostatically formed into a bellow with rounded and widely spaced folds.

Welded bellow

These bellows are made by welding washer-like plates of thin metal together at both the inner and the outer circumference of the washers like plates. A welded type bellow has more folds per unit length when compared to the forged bellows. The welded bellows are shorter in length.

Difference between a forged bellow and a welded bellow

Durability

The forged bellow has good durability because these bellows are constructed from a single piece of metal and because of this the forged bellow would have good cycle life. In the case of the welded bellows, the reliability will be low because this type of bellow has small welded spots, because of this heat would be affected to this bellow, and thus its cycle life will be less.

Usage in valve

The forged bellow would have a wide opening between piles of bellows, due to this the bellow function won’t be affected by bits of foreign matter in the fluid. In the case of a wedged type bellow, the opening between piles will trap the foreign material in the fluid, and eventually, this would lead to the failure of the bellow.

Quality control

The forged type of bellow is really easy to test for quality because the forged bellows are constructed uniformly. In the case of welded bellows, it is very difficult to inspect the welded spots for quality and because of this, quality control will be really difficult.

Primary stem seal

The bellow seal valves have metallic bellow, the piston valves have piston rings and the conventional valves have gland packing.

Stem leakage

The bellow seal valve has no stem leakage, while in a piston valve stem leakage could occur when the rings wear out. In the case of the conventional valve, stem leakage is very common because of the friction between the stem and the gland.

Packing replacement and replacement cost

In the bellow seal type replacement can’t be done, while in the piston valves the rings need to be changed frequently. In the case of the conventional valve, packing needs to be replaced frequently too. The replacing costs of the piston and the conventional valve are very high.

Media loss

There won’t be any media loss in the bellow type, while in the case of the conventional and the piston valves there could be large media loss.

Valve life

The bellow seal valves has good life while the piston and conventional type only has very low life.

Safety

The bellow valves are very safe and any media can be used, while the piston valves can only be used for limited media like hot water and steam. The conventional valve is really unsafe if the media is hazardous.

Cost

The initial cost of the bellow seal valve is very high but after that, there will be only less maintenance. The piston valve cost is high when considering its benefits, while the conventional valve cost is initially very low but its maintenance cost is very high after some years.

- Long life

- Less maintenance

- There won’t be any steam loss, and there won’t be any media loss

- Monitoring costs of this valve is very low

- It can be used for applications where leakage should be zero

- Safe and clean operation can be achieved

- Heat transfer media

- It can handle highly hazardous fluids

- Vacuum and high ultra-vacuum

- It can be used in nuclear power plant and also with heavy water plant

- These valves are used for costly fluid applications