Table of Contents A check valve works on the basis of differential pressure, as was previously mentioned. A check valve needs to reach what is known as the cracking pressure, or minimum upstream pressure, in order to open. The cracking pressure varies with the size and configuration of the check valve. The valve opens to let fluid in when the upstream pressure hits the cracking pressure. When the flow tries to go from the exit to the inlet and the upstream pressure drops below the cracking pressure, back pressure is produced. The flow stops and the check valve closes at this moment. A check valve's closing mechanism varies based on the kind and design of the valve. Usually, the closure process is aided by spring or gravity pressure.

Because a check valve may only operate in one way, the flow direction is indicated by an arrow provided by the manufacturer on the valve body.

JONLOO Check Valve types can be divided into the following designs:

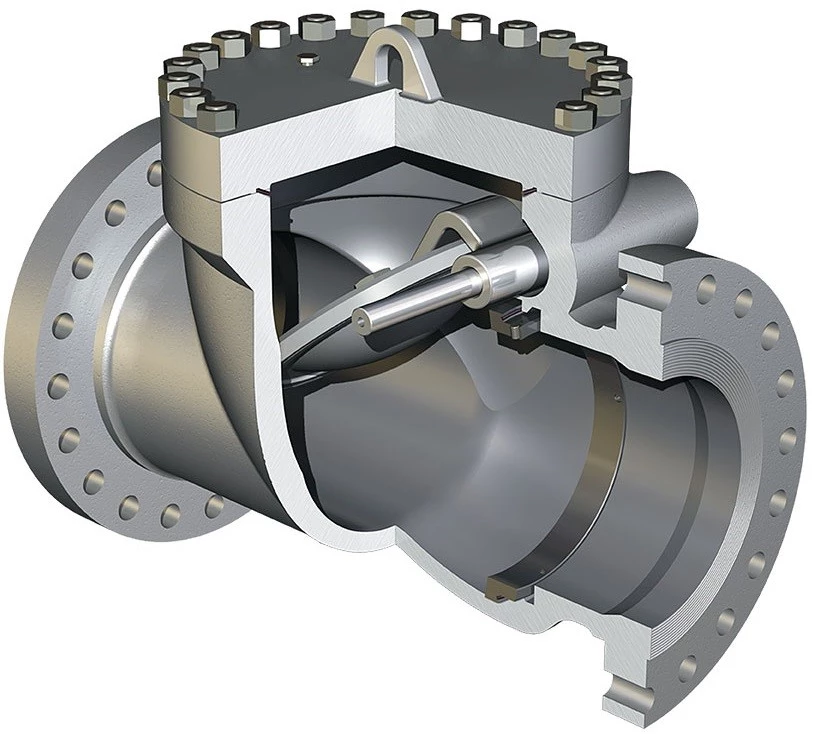

Swing Check Valve

A simple swing check valve is made up of a disk that is attached to a hinge, a bonnet, and the valve body. When the upstream flow is stopped to prevent backflow, the disk swings back to the valve seat, swinging away from the valve seat to permit forward flow.

The swing-style disc When the check valve fully opens or closes, it is unguided. There are numerous disk and seat designs available to satisfy the needs of various applications. When the pressure drops, the valve automatically closes, allowing complete, unhindered flow. In order to stop backflow, these valves are completely closed when the flow drops to zero. There is extremely little turbulence and pressure drop in the valve.

Industry Codes and Standards

- Valve Design: BS 1868 / API 6D

- Pressure Testing: BS 6755-I

- Face To Face: ANSI B 16.10

- Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS / JIS Std.

- Butt Weld End: ANSI B 16.25

- Face to Face: ANSI B 16.10

- Socket Weld End: ANSI B 16.11

- Screwed End: ANSI B 1.20.1(BSP/NPT)

Because of the valve's small face-to-face dimensions and light weight, wafer check valve may be installed between companion flanges in a straightforward, space-saving manner.

The valves can be installed between companion flanges of different standards that are slip-on or weld neck style.

They were created specifically for uses where a low pressure loss is necessary. The valve will open and close with a very small pressure differential across the valve disc.

The disc seat and eccentric disc shaft combination ensures a positive shut-off of the returning media. Because of their affordable price and small design, wafer check valves are increasingly the preferred kind of check valve for the majority of applications.

A lift-Check valve's seat design is comparable to that of a globe valve. Typically, the disc takes the shape of a ball or a piston.

Lift check valves work especially well in high-pressure, high-velocity applications. The disc in lift check valves is precisely directed and fits into the dashpot precisely. Installing lift check valves in horizontal or vertical pipes with upward flow is appropriate.

Flow for elevation Always place check valves beneath seats. The upward flow pressure forces the piston or ball within the guides to rise from the seat as the flow enters. Gravity and backflow combine to push the piston or ball into the valve seat when the flow stops or reverses.

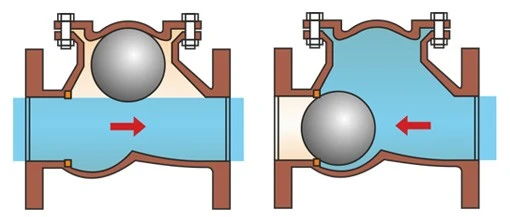

Ball check valves are straightforward and frequently seen in low-head systems and small pumps. Ball check valves close at pressures lower than the breaking pressure using a spherical ball clapper that is either free-floating or spring-loaded. In order to direct the ball into the sealing seat and produce a strong seal, the sealing seat is conically tapered. But with repeated usage, these valves can easily wear out and need regular repair.

A butterfly check valve is also known as a double-disc, split-disc, folding-disc, or dual-plate check valve. The term implies that in a forward flow, two halves of the disk move toward the centerline, and in a reverse flow, two halves open and rest on the seat to stop the movement.

These check valves work well in gas pipe systems as well as low-pressure liquid systems. When convenience and room are key considerations, this option is better due to its lightweight and small design. In addition, compared to other varieties, it is 80–90% lighter and requires less installation and maintenance than a traditional full-body check valve.

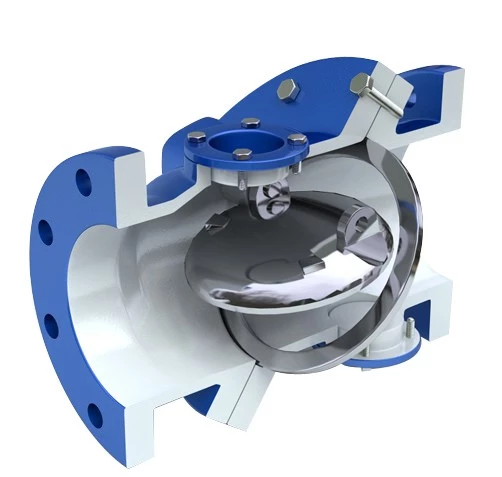

The tilting disc check valve resembles an eccentric butterfly valve in appearance. The valve body has two flanges and is not very long. A shaft that is eccentrically positioned from the body centerline in both the horizontal and vertical axes is used to position the disc.

The lower part of the disc takes up more space in the flow channel as a result of the shaft's twofold eccentricity. The disc then starts to open at very low flow rates as a result. For this reason, pulsing flows and pumping systems with modest flow rates frequently employ tilting disc check valves.

Gravity causes the disc to shut during flow reversal. As the disc returns to its closed position, the upper portion of the disc above the shaft centerline presses against the flow, functioning as a hydraulic brake to cushion the disc. Levers and weights are optional accessories for tilting disc valves that allow you to customize the valve's closing characteristics. The tilting disc check valves are therefore a good choice for lowering the possibility of water hammering.

A stop check valve is a single body that houses two valves. It can serve as a globe valve to regulate or isolate an area. Once more, it can function as a check valve to stop backflow. The Stop check valve, in contrast to other check valves, includes an extra external control mechanism that operates in an angular or perpendicular manner. In steam services such as power plants, turbine cooling, boiler circulation, steam generators, and safety systems, stop check valves are widely used.

Rubber flexing diaphragms or self-centering discs are used in diaphragm check valves to stop backflow. Upon an increase in the inlet pressure, the diaphragm flexes, allowing flow to commence. Diaphragm check valves come in two different varieties:

- Free-floating Normally Open Valve

- Fixed Flexing Normally closed Valve