Imagine a society in which every relationship is a pledge of honesty and dependability. A properly connected valve strengthens the system as a whole, much like a strong handshake between parts. It's a convergence of trust rather than just a fusion of metals. Selecting the appropriate valve connection type means building a stronghold that can withstand attacks from corrosion and high pressure. It goes beyond simply assembling a system. It's similar to selecting the ideal valve end face—a choice that can determine whether a system succeeds or fails.

Imagine a society in which every relationship is a pledge of honesty and dependability. A properly connected valve strengthens the system as a whole, much like a strong handshake between parts. It's a convergence of trust rather than just a fusion of metals. Selecting the appropriate valve connection type means building a stronghold that can withstand attacks from corrosion and high pressure. It goes beyond simply assembling a system. It's similar to selecting the ideal valve end face—a choice that can determine whether a system succeeds or fails.Every penny matters in this complex dance of economics, isn't that right? Selecting the appropriate valve connection type is like making an investment in a savings treasure chest. Similar to a strong metal plate defending different parts of the world from the effects of aging, the proper connection prolongs the life of the system and reduces the need for regular maintenance.

The continuous melody of operation is the symphony of cost-saving that goes beyond the first notes of purchase. It's not just about the thread type or valve port; it's also about the harmonious marriage of longevity and efficiency that plays nicely with frugal spending.

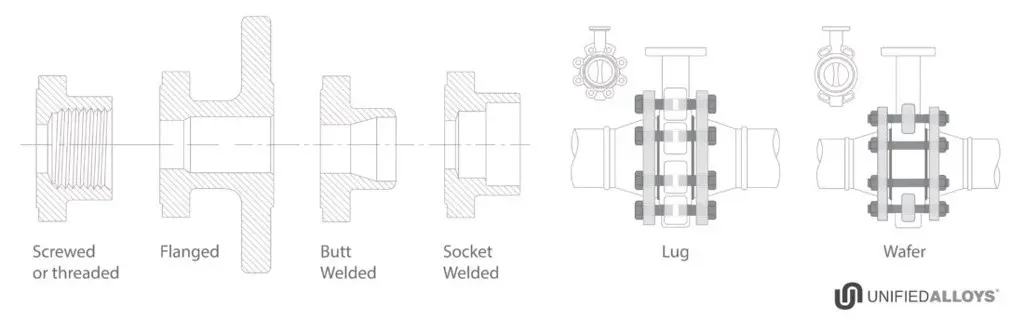

Threaded connections, the masters of the valve industry, use the dexterity of a pneumatic actuator to carefully create the connections between pipes and valves. NPT threads weave the fabric of American national standards in this world, whispering tales of tradition with each spiral. To appreciate the beauty of a tiny valve leaving its mark on the vastness of a pipe system is to comprehend the essence of a threaded connection. It's a story that embodies industry norms, with every twist serving as a new verse in the song of usefulness. Now, there are ups and downs in the tale of threaded connections.The benefit is similar to how easy it is to connect a soft hose to a release ring; speed and simplicity are the key factors here. However, there's a catch: the possibility of leaks sends a warning signal, much like a single hinge under excessive stress.

Strong guardians of the valve world, welded connections cling to one another with a permanence as old as the mountains. Like a solenoid valve standing sentinel against the torrents, the process, riveting as any industrial application, creates a bond that withstands the ravages of time and pressure.

Choosing a welded connection in the vast array of options is similar to picking a steel valve for its unwavering strength. It works best in situations where the pipe sizes necessitate a warrior's will, where the enemy isn't just the environment but also the forces trying to compromise the system's integrity. Welded connections rise to the challenge when wall thickness demands a fortress-like bond, providing a defense against possible leaks and failures.

The diplomats of the valve world, flanged connections combine strength and sophistication. With the accuracy of an automotive engineer, they are bolted together to resemble solid metal plates that are prepared for a grand assembly. In industrial applications, where strong yet detachable joints are essential, these connections serve as the cornerstone. There are scales unique to the majesty of flanged connections. The simplicity of assembly and disassembly is evident on one side, akin to a hinged clamp that provides flexibility and security. However, the need for additional room and the possibility of bolt-hole misalignment cast a shadow, serving as a reminder that even the strongest connections need to be handled with a balance of caution and respect.

The graceful performers of the valve world, compression connections, convey their strength with such grace. A compression nut tightens, drawing the pipe and the valve body together in a close, whisper-like embrace that produces a seal that is as forgiving as it is tight, akin to the soft grasp of a hose clamp. These connections are seen in more subdued settings, such as residential plumbing systems, where the subtleties of daily flow take precedence over the dramatic effects of high pressure. Within the walls of our homes, there exist unsung heroes who toil tirelessly and invisibly to make sure that every drop of water travels to its intended destination with the promise of purity.

The valve world's negotiators, Union connections, are skilled at reaching a compromise. They combine various system components with a union connection that makes disassembly possible without the hassle of a complete system shutdown. This connection, which recognizes the importance of harmony, proposes a truce between the demands of upkeep and security. Union connections provide a middle ground, akin to a single hinge door that can swing both ways, when placed against their kin. While they might not have the strength or durability of flanged connections or welded connections, they do have a great deal of versatility that is useful in the constantly evolving fields of residential plumbing and industrial applications.

Similar to a general observing a battlefield from a position of observation, manifold-mount connections, the strategic planners of the valve world, provide a centralized point of control. They make it possible for a single valve body to serve as the hub of several routes, precisely controlling flows with the accuracy of an ASME standard. The manifold-mount is a towering device that provides advantages akin to those of a well-maintained machine. They mimic the industry standards established by the American National Standards Institute by reducing the need for multiple connections, minimizing potential leak points, and producing a system that is both aesthetically pleasing and highly functional.

| Connection Type | Applications | Required Accessories | Pros and Cons |

| Threaded | General plumbing, small systems | Teflon tape, wrench | Easy to install with common tools, but can be prone to leaks if not sealed properly. |

| Welded | High-pressure systems, industrial | Welding machine, safety gear | Extremely durable and leak-proof, but permanent and difficult to modify. |

| Flanged | Large industrial systems | Gaskets, bolts, nuts | Strong and can be dismantled, but requires space and precise alignment. |

| Compression | Residential plumbing, small pipes | Compression nut, ferrule | Simple to fit without soldering, not suitable for high-pressure applications. |

| Union | Systems requiring maintenance | Union fitting | Facilitates easy disconnection for maintenance, but is bulkier than other fittings. |

| M anifold-Mount |

Complex systems, multiple lines | Manifold block, seals | Centralizes connections to reduce leaks, complex initial setup. |

In the other direction, the BSP standard tells its own story. It is a dialect that has spread throughout the globe, a European norm that is on par with its American equivalent, guaranteeing a varied and inclusive conversation about connections.

Next, there is the Metric thread standard, or M, which acts as a universal translator to connect disparate systems. It is the industry standard that guarantees constant communication flow regardless of the source by enabling a smooth exchange between valve port and pipe.

Choosing the proper valve connection type is like choosing the appropriate armor for combat in the world of high pressure. This is a choice that can protect an industry's vitality by guaranteeing that each valve pipe and connection valve is strong enough to withstand an attack of force.

Within the more subdued world of residential plumbing, the whispering connections of the connecting valve and connecting pipe guarantee that our homes remain sanctified, whispering dependability and even more softly when it comes to maintenance.

Installing valve connections is a craft that requires dexterity and attention to detail. In order to ensure that every valve pipe fitting is more than just a connection but rather a guarantee of dependability, the procedure calls for the proper pipe connections and the discernment to use pipe tape when needed.

Any system's worst enemy, leaks, are frequently the first indications that a connection is failing. A steady hand—one that understands when to replace a pipe thread connection and when to tighten a hose clamp—is necessary for both their identification and solving.

Then there is upkeep, which is the mantra of longevity. Every type of valve connection has a unique song, and understanding the words can make the difference between a system that works well and one that just gets by. Maintenance is the tune that makes sure the music never stops, whether it is the routine inspection of the bolt holes in a flanged connection or the careful tightening of a compression nut. Ultimately, valve connections are critical. They resemble our systems' and pipes' unsung heroes. Making the correct choice is similar to ensuring that our systems are reliable and robust. It involves more than just assembling parts; it involves ensuring that everything functions well and endures a long time. Thus, we have to commend those tiny connectors highly. Even though they are tiny, they have a big impact on maintaining everything in working order.