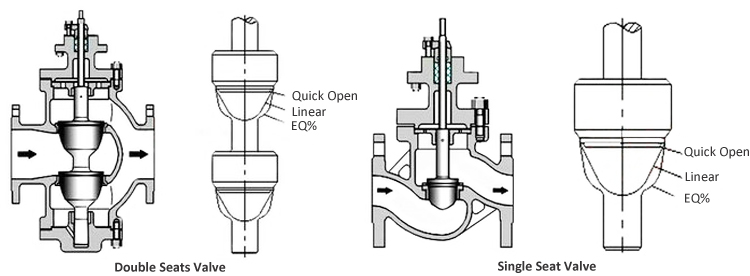

The control valve construction is mostly like a globe, this control valve could be either, single-seated or double seated.

From the name we are able to clearly observe that the first is just one seat, and the other has a double seat, as suggested by its name may be the distinction between the valve seat. Double seat control valve has two seats may be the valve body, and also the single sitting down control valve has one seat within the valve body.

A single-seated valve has a single seat and a single plug, in this type of valves the process pressure would reach on the bottom side of the plug and this will create a force upward in the valve stem. The actuator in this valve can control this force or it is capable to act against the force created by process pressure. So the actuator can move or hold the stem downward by controlling this force. The actuator in this valve must be able to control this force but it is a difficult task if the valve is big. If the valve is big then the created pressure will be big too and the actuator must be capable to handle this force, and because of this, the single-seated valve is not used for high-pressure applications. Single seated valves are suitable if we need a higher degree of shut off, single-seated valve or single-port valves are in many forms they are the globe, angle, bar stock, etc. The single-seated valve has top guided construction and it has good flow capacity than the top and the bottom guided valves. The selection of actuators and plugs for a single port valve must be done according to the pressure of the fluid.

- It provides high rangeability and tight shut-off

- A reversible plug is available

- A large actuator is needed

- Pressure recovery is low

- Only used for small diameter applications

- The force required to drive the stem is high

These valves are used to control a large range of process parameters and because of this feature, it is used in oil and gas production, power generation.

A double-seated valve is a top and bottom guided valve and these valves have two plugs and two seats. In this type of valve, the line pressure acts upward in one plug and downward in the other, and because of this, the force is balanced. These valves are used for high-pressure applications. Double port valves are pressure balanced valves and they can close the valve plug against higher operating pressure. Tight shut off is not possible as in single-seated valves, these valves have fast flow response and greater capacity than single-seated valves and they are used when tight shut off is not needed. In this valve, the two ports cannot be opened at the same time. Double port valves can do the diversion of the flow from a single flow line to one or more outlets.

- It can be used for larger valves

- It can be used for high flow and high-pressure services

- Tight shut off is not possible

- Due to the erosion and cavitation, the body parts could wear out

- 1) Single seated control valve has only one trim and one seat, double seated control valve has two trims and two seats.

- 2) Single seated control valve has a small leakage, and it is easy to achieve strict sealing and cutting; Double seated control valve has a large leakage.

- 3) Single seated control valve allows a small differential pressure;Double seated control valve is subjected to a small unbalance force and allows a large differential pressure.

- 4) Single seated control valve has a small flow capacity, and double seated control valve has a large flow capacity. Compared with other control valves of the same diameter, double seated control valve can flow through more fluid, and the flow capacity of the same diameter double seated control valve is about 20%-50% larger than that of single seated control valve.

- 5) Due to the large thrust of the fluid medium to the valve trim, that is, the unbalanced force is large, therefore, in the application of high pressure difference and large diameter, it is not suitable to use a single seated control valve; Double seated control valve is not suitable for high pressure differential applications. Due to complex flow path, it is not suitable for the control of fiber containing media and high viscosity fluids.

The pneumatic double seat control valve seat has lower and upper valve plugs, and also the fluid flows in the left side of body, goes through the valve seat and plug, and flows out of the right side. It may flow more medium than the usual single-sitting down control valve with similar nominal diameter, and also the flow capacity is elevated by about 20% to 25%. The forces functioning on the lower and upper plug can cancel one another out, therefore the imbalance pressure is small , the operating pressure difference is big.

- 1.The options from the single seat control valve: the leakage is small, the unbalanced pressure is big, and also the allowable pressure difference is smaller sized compared to double seat valve.

- 2. The characteristics of double seat control valve: large allowable pressure difference. It is almost always especially appropriate for applications with large flow rates, ruthless drops and enormous leakage.