Like all contemporary technology, valves have developed over time and become much more sophisticated. Valves, which are categorized as fittings or small equipment components, are much more complicated and employ automated processes. They function as controls for everything, including power production, sewage treatment, and water flow.

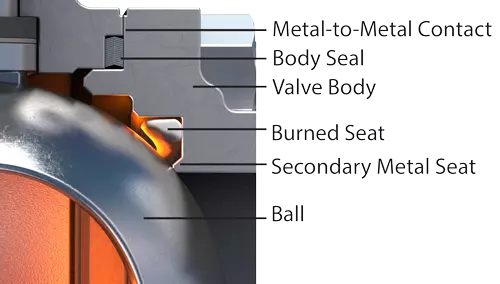

Valves are essential for putting out fires, among other things. The spring-loaded valves, when activated by heat, stop fuel from starting a fire. This fuel is often a liquid, like oil. The fluid that started the fire is cut off when the valves snap shut when exposed to heat. The valves minimize leakage and halt the flow that could start a fire. Every type of equipment on the market, no matter how big or small, has valves. There are numerous compelling arguments for using a fire-safe valve. The most obvious justification is to preserve human life. When working with combustibles, a fire-safe valve is one of, if not the most important, technological components. There are tangible advantages as well, such as lowering insurance costs and safeguarding machinery and the environment. A ball valve is among the most widely used fire-safe valves. A metal ball floats between two seats in this apparatus. The seats of the valve warp when it gets too hot, releasing the ball against the end cap and creating a tight metal-to-metal seal to stop further leaks. In order to stop additional leaks, these seals may also have stem seals with the top portion submerged in the fluid.

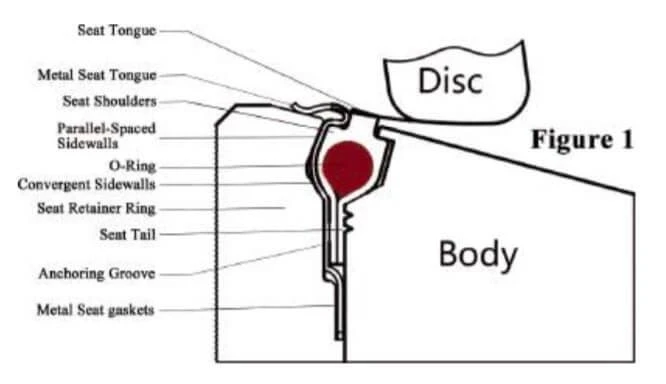

A fusible link valve is another popular kind of fire-safe valve. Fusible link valves keep pressure on a spring pack by using a link and a trigger assembly. This maintains the valve open in normal, safe conditions. The fusible link breaks as soon as it reaches an excessive temperature when a fire breaks out and poses a threat. As a result, the valve can be closed by the spring pack, stopping additional fluid flow. These valves feature two seats—a metal seat intended for isolation and a TFE seat—as well as graphite seals that improve the seal's protection.

A fire-safe butterfly valve is a common choice for safety because it is more affordable. Rods in discs that rotate either with or against the flow are found in butterfly valves. The valve is a quarter-turn valve, meaning that a quarter turn will cause the valve to be fully closed or open. Within that quarter turn, these valves can be opened or closed as much as the circumstances demand. A fire-safe butterfly valve is a reliable, safe choice because it's very simple to operate in an emergency.

A fusible link valve is another popular kind of fire-safe valve. Fusible link valves keep pressure on a spring pack by using a link and a trigger assembly. This maintains the valve open in normal, safe conditions. The fusible link breaks as soon as it reaches an excessive temperature when a fire breaks out and poses a threat. As a result, the valve can be closed by the spring pack, stopping additional fluid flow. These valves feature two seats—a metal seat intended for isolation and a TFE seat—as well as graphite seals that improve the seal's protection.

A fire-safe butterfly valve is a common choice for safety because it is more affordable. Rods in discs that rotate either with or against the flow are found in butterfly valves. The valve is a quarter-turn valve, meaning that a quarter turn will cause the valve to be fully closed or open. Within that quarter turn, these valves can be opened or closed as much as the circumstances demand. A fire-safe butterfly valve is a reliable, safe choice because it's very simple to operate in an emergency. Fire-safe valves come in three tiers. Although valves marked as "fire-safe by design" are constructed to withstand fires, their fire safety cannot be guaranteed in the absence of testing. Despite not having received regulatory third-party approval, fire-safe tested valves have undergone testing. Lastly, a third party has certified fire-safe approved and certified valves.

An API 607 fire-safe valve is the most reliable type of valve. One of the common fire safety tests for valves in the petroleum sector is API 607. These standards were created by the American Petroleum Industry, or API, and indicate how reliable a valve should be in an emergency.

Fire-safe valves come in three tiers. Although valves marked as "fire-safe by design" are constructed to withstand fires, their fire safety cannot be guaranteed in the absence of testing. Despite not having received regulatory third-party approval, fire-safe tested valves have undergone testing. Lastly, a third party has certified fire-safe approved and certified valves.

An API 607 fire-safe valve is the most reliable type of valve. One of the common fire safety tests for valves in the petroleum sector is API 607. These standards were created by the American Petroleum Industry, or API, and indicate how reliable a valve should be in an emergency.The valve is subjected to a 30-minute test in this manner. Typically, a fire, withdrawal, and containment are necessary following thirty minutes of fighting. Thermocouples and calorimeter cubes are used to measure the intensity of heat generated when a pressurized valve filled with water is subjected to temperatures as high as 1000 degrees Celsius. Leakage is measured both inside and outside during the test, and it should ideally fall within an acceptable range. After the test, components like the seal, seats, and shell that are capable of withstanding pressure are inspected and tested further.

The API 607 test is for quarter-turn and nonmetallic seating valves under pressure. The API 6FA test is used for valves that meet API 6A and API 6D valve requirements and have metal seating.

It is imperative to have a reliable quality valve for unexpected situations. Fire safety is essential for preserving everything, including property and lives. Superior equipment can have a profound impact. You should therefore confirm that the valve you currently own is sturdy.

We have a large selection of fire-safe valves at JONLOO. We offer fusible link butterfly valves and hybrid fusible link-ball valves in stainless steel, ductile iron, and carbon steel. The links have a temperature range of 165F to 300F. With our instructions, installing these valves is simple.