What are Fire Safe Valves

Fire safe valves are specialized valves designed to prevent the spread of fire in industrial settings. These valves are typically used in pipelines that transport flammable materials such as oil, gas, or chemicals.

In the event of a fire, fire safe valves are designed to shut off automatically, preventing the spread of flames and reducing the risk of an explosion. They are typically made of materials that can withstand high temperatures and are designed to maintain their integrity even in extreme conditions.

Fire safe valves are an important safety feature in many industrial settings, as they help to protect workers and prevent damage to equipment and property.

Types of fire Safe Valves

There are various types of valves that have fire safe designs, such as ball valves, gate valves, globe valves, and check valves. The exact design of a fire safe valve will depend on the specific application and the level of risk involved.

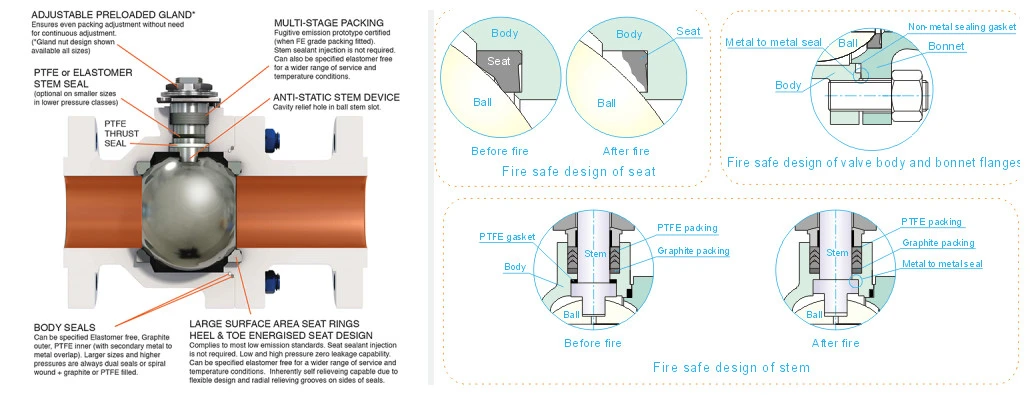

Fire safe design typically involves the use of materials that are capable of withstanding high temperatures and preventing the leakage of flammable substances. This might include the use of metal-to-metal seals, graphite packing, or ceramic materials. Additionally, fire safe valves may be designed to close automatically in the event of a fire, or to have a secondary barrier that prevents the release of flammable substances even if the valve fails.

Fire-safe Ball Valves

The most common type of fire-safe valve is a ball valve. Ball valves are a popular choice for fire-safe applications because they have a simple design, are easy to operate, and provide reliable shut-off capabilities. Additionally, ball valves are often made of materials that can withstand high temperatures and are resistant to corrosion, which makes them ideal for use in environments where fire safety is a concern. However, the specific type of fire-safe valve that is most appropriate for a given application will depend on a variety of factors, such as the type of fluid being transported, the operating conditions, and the specific fire safety requirements of the facility.

Butterfly Valves

More cost-effective, a fire-safe butterfly valve is a popular option for safety. Butterfly valves have rods in discs that turn with or against the flow. The valve is a quarter-turn valve which makes the valve fully closed or open when turned a quarter turn. These valves can be restricted or released as much as the situation requires within that quarter turn. A fire-safe butterfly valve is extremely easy to use in an emergency, making it a safe, trustworthy option.

Why Should You Use Fire-Safe Valves

Fire-safe valves are an important component in ensuring safety in industrial settings. These valves are designed to prevent the spread of fire by shutting off the flow of flammable liquids or gases in the event of a fire. This can help prevent catastrophic accidents and minimize damage to property and personnel.

In addition to their safety benefits, fire-safe valves are also required by many regulations and industry standards. For example, the American Petroleum Institute (API) requires the use of fire-safe valves in certain applications to reduce the risk of fires and explosions.

So, if you work in an industrial setting where flammable liquids or gases are present, it's important to consider using fire-safe valves to ensure the safety of your operation and comply with regulations.

The Benefits of Fire Safe Valves

One of the most essential roles valves do is stopping fires. Activated by heat, the spring-loaded valves prevent fuel from feeding a fire. This fuel is generally a liquid such as oil. When exposed to heat, the valves snap shut, and the fluid which fueled the fire is shut off. Fire safe valves are designed to prevent the spread of fire in industrial settings where the presence of flammable gases or liquids make fires a significant risk. The benefits of these valves are that they help to reduce the likelihood of fires starting and spreading, which can help to protect people and property.

Fire safe API 607 Standard

API 607 is a standard that specifies the requirements for testing and evaluating the fire-resistance of valves that are designed for use in critical applications, such as those found in the oil and gas industry. The standard was developed by the American Petroleum Institute (API) and is widely used as a benchmark for evaluating the safety and performance of these types of valves. The API 607 standard includes specific testing procedures and criteria for determining whether a valve is able to withstand exposure to fire and maintain its integrity and functionality.