Spirax Sarco is a company that specializes in the production of steam system solutions and control systems. Some of the products they

produce include steam traps, control valves, pressure regulators, and temperature control valves. These products are used in a variety of industries,

such as food and beverage, pharmaceuticals, and oil and gas, to namea few.

Spirax Sarco is actually a well-known company that specializes in steam engineering solutions, including steam traps.

Spirax Sarco is known for their high-quality steam traps and other steam-related products, and they have a reputation for providing reliable and efficient solutions for industrial and commercial applications.

What is a steam trap

A steam trap is a device used in steam systems to remove condensate (water) and air from the system without allowing any steam to escape.

Steam traps work by opening to allow condensate to drain out of the system, and then closing to prevent steam from escaping.They are important

because if condensate is allowed to accumulate in a steam system, it can cause damage to equipment and reduce efficiency. There are different types

of steam traps, including mechanical, thermostatic, and thermodynamic traps, each with its own unique way of functioning.

The types of Steam Trap

There are several types of steam traps, each with its own unique design and function. Here are some of the most common types:

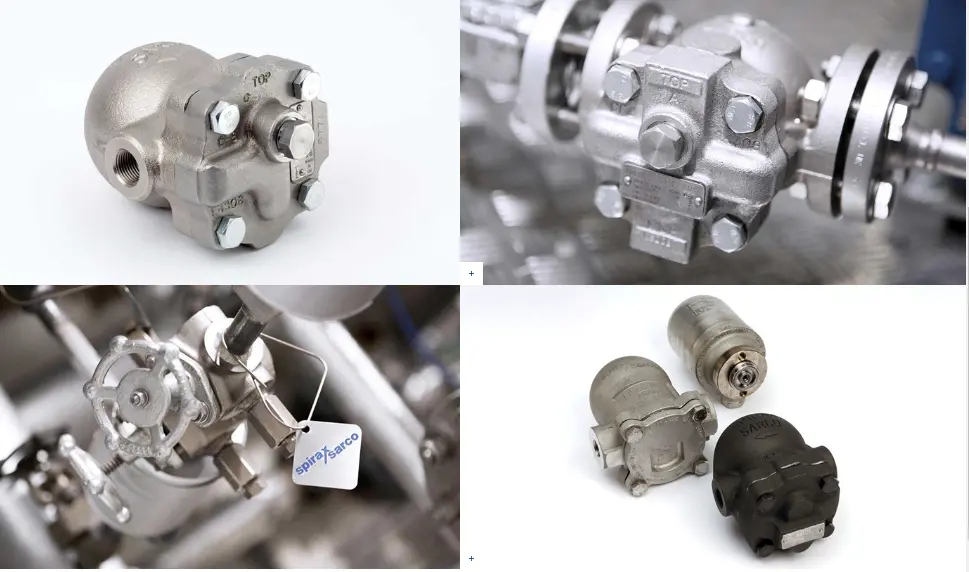

1. Float and thermostatic steam traps

These traps use a float to regulate the flow of condensate and steam. When the condensate level rises, the float rises and opens the trap, allowing the condensate to drain out. When steam enters the trap, the float sinks and closes the trap, preventing steam from escaping.

FT14 - Closed float trap - flanged, threaded connections

FT14 / FT14HC - Closed float trap (1"HC,1"1/4,1"1/2 and 2")

FT43 - Closed float trap -DN25-50, DN80 & DN100

FT44 - Closed float trap DN15 to DN50, DN80 & DN100

2. Inverted bucket steam traps

These traps use an inverted bucket that floats on top of the condensate. When steam enters the trap, it fills the bucket and causes it to tip over, opening the trap and allowing the condensate to drain out. When the steam condenses, the bucket becomes heavier and tips back, closing the trap. Spirax Sarco Inverted Bucket steam trap is available in sizes ranging from 1/2" - 3".Inverted bucket traps are the most robust type of the mechanical traps. It is able to resist waterhammer. With check valve fitted in the inlet, they can be used with superheated steam. It is available with a wide selection of valve orifices for precise pressure and load matching.

3. Thermodynamic steam traps

These traps use a disc that moves up and down in response to changes in temperature and pressure. When steam enters the trap, it lifts the disc, allowing condensate to drain out. When the steam condenses, the disc falls back into place, closing the trap. Spirax Sarco Thermodynamic steam trap is available in sizes ranging from 1/4" to 1". Thermodynamic steam traps combine reliability, simplicity and efficiency of operation. With just one moving part - a hardened stainless steel disc - they give a blast discharge with clean, tight shut-off. It is able to withstand superheat, water hammer, corrosive condensate, freezing and vibration.

The TD trap is the first choice for removal of condensate from steam distribution systems.

4. Bimetallic steam traps

These traps use two metals with different coefficients of expansion to control the flow of steam and condensate. When steam enters the trap, it heats up one of the metals, causing it to expand and open the trap. When the steam condenses, the metal cools and contracts, closing the trap.The Bimetallic steam trap is available in sizes ranging from 1/4" to 4". Spirax Sarco Bimetallic steam traps can conserve energy by discharging sub-cooled condensate in those applications which utilize sensible heat. The most robust of all the thermostatic steam traps. It is able to withstand waterhammer and corrosive condensate.

5. Balanced Pressure Steam Traps

A balanced pressure steam trap is a type of device that is commonly used in steam systems to remove condensate (water that forms when steam cools down) from the system. It operates by using the difference in pressure between the steam and the condensate to open and close a valve, allowing the condensate to be removed while preventing steam from escaping. The "balanced pressure" part of the name refers to the fact that the trap is designed to maintain a balance between the pressure of the steam and the pressure of the condensate, which helps to ensure that the trap operates efficiently and effectively. Spirax Sarco Balanced Pressure steam trap is available in sizes ranging from 1/4" - 1". Balanced pressure thermostatic steam traps adjust automatically to varying steam pressures. It is excellent air venting characteristics during plant start-up and during normal operation. Large discharge capacities for their size. Robust design of the internals gives a good life expectancy.

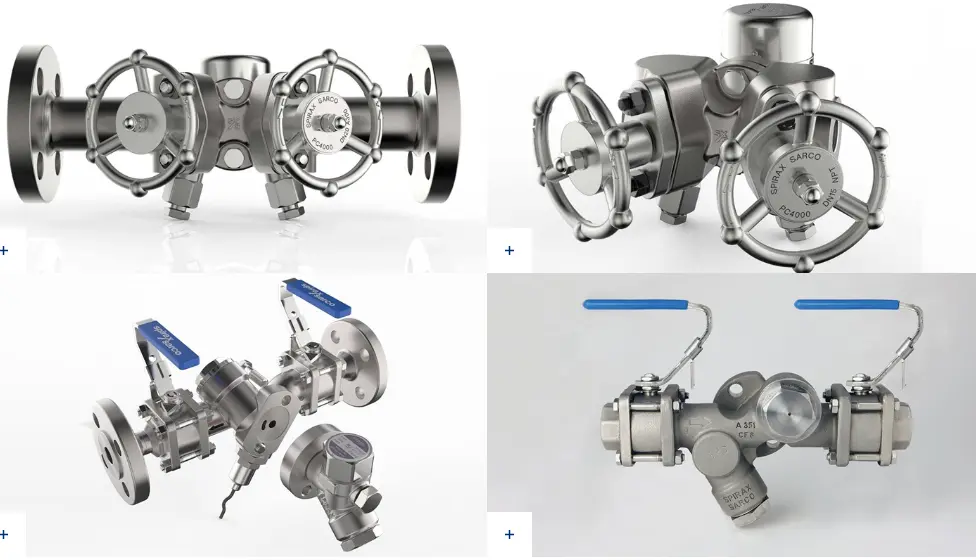

6. Swivel Connectors and Traps

Swivel connectors and traps are plumbing components used to connect pipes and fixtures in a plumbing system.

A swivel connector is a type of fitting that allows pipes to be joined together at an angle or rotated to a certain degree. These connectors are used to make plumbing installations more flexible and adaptable to different spaces and configurations.

A trap, on the other hand, is a component that is used to prevent sewer gas from entering a building. It is typically installed beneath a sink or other fixture and works by trapping a small amount of water in a bend in the pipe. This water creates a barrier that prevents sewer gas from passing back up into the building.

Swivel connectors and traps are both important components of a plumbing system, and they play a crucial role in ensuring that water flows properly and that buildings are safe and free from harmful gases.

Next: Baelz 373-E07 Actuators

Previous: The Lining Material for Lined Valves