What is metal seated ball valve?

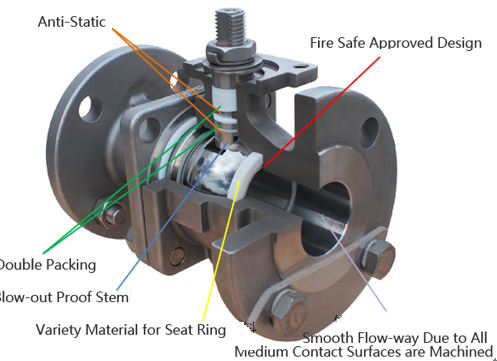

A metal seated ball valve is a type of valve used to regulate the flow of fluids in industrial pipelines.

It is designed with a metal seat that provides a tight seal between the ball and the valve body, ensuring

that the fluid does not leak through the valve. These valves are commonly used in harsh and high-temperature environments, where other types of valves may not be able to withstand the conditions.

The metal seat provides increased durability and resistance to wear and tear, making it ideal for use

in applications where there are abrasive materials or high flow rates.

What is soft seated ball valve?

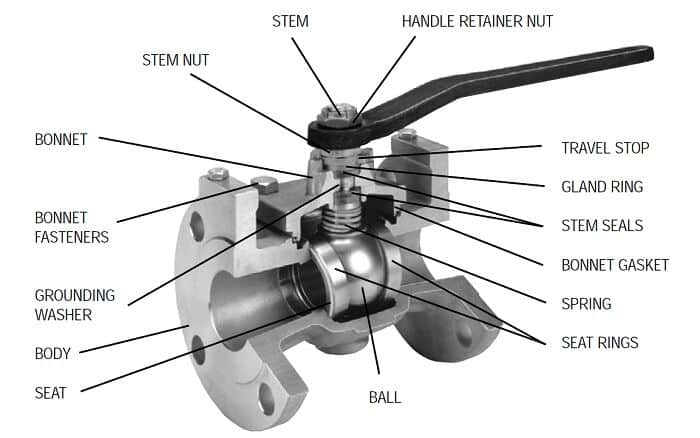

A soft seated ball valve is a type of valve with a ball-shaped disc inside that controls the flow of fluid through a pipe or other system. The term "soft

seated" refers to the material used to create a seal between the ball and the valve body. In this

type of valve, a soft material like Teflon or rubber is used to create a tight seal when the valve is

closed. This helps prevent leaks and ensures a smooth, easy operation when opening and closing

the valve. Soft seated ball valves are commonly used in a variety of industries, including oil and

gas, chemical processing, and water treatment.

What is the advantages of soft seated ball valves.

Soft-seated ball valves offer several advantages over their metal-seated counterparts.

Firstly, they provide a better seal, which reduces the likelihood of leaks and ensures that the

valve operates more efficiently. The soft seats conform to the ball and create a tight seal that

prevents fluid from leaking through the valve.

Secondly, soft-seated ball valves require less torque to operate, making them easier to turn and more user-friendly. This can be particularly useful in applications where the valve needs to be opened

and closed frequently.

Finally, soft-seated ball valves are less prone to damage from particulate matter, which can

cause metal-seated valves to leak or fail. The soft seats are more forgiving and can withstand some damage

from debris without compromising the valve's performance.

Overall, soft-seated ball valves are a reliable and efficient option for many applications, particularly those

that require a tight seal and frequent operation.

What is the advantages of metal seated ball valves.

Metal seated ball valves have a few advantages over other types of valves. One of the main

advantages is their ability to withstand high temperatures and pressures. This makes them ideal

for use in applications where there is a lot of heat or pressure involved, such as in the oil and gas

industry.

Another advantage of metal seated ball valves is their durability. They are designed to last a long

time and can withstand a lot of wear and tear. This means that they require less maintenance and

are less likely to fail over time.

Finally, metal seated ball valves are also very precise. They can be adjusted to very specific settings,

which makes them ideal for use in applications where accuracy is important, such as in the chemical

processing industry.

Overall, metal seated ball valves are a reliable and durable option for a variety of applications where

high temperatures, pressures, and precision are required. Even though metal seated valves are more expensive, the cost of downtime resulting from failure, coupled with the replacement of soft seated

valve break downs, should be factored in. The efficiency and longevity of metal seated ball valves

will pay off and counteract the higher price. Bottom line, metal seated ball valves are the best, long lasting, economical options for critical applications.

| Valves | Metal seat | Soft seat |

| Material | Copper alloy (for low-pressure valves);

Chrome stainless steel (for medium and high-pressure valves); Satellite Seat Surface (High temperature and pressure valves and highly corrosive valves); Nickel-based alloys (for corrosive media); Metal-ceramic sealing material, etc |

The elastic nonmetallic material such as PTFE(Temperature -50°F to 400°F);

modified PTFE( Temperature -50°F to 450°F); Delrin(High pressure up to 5000psi dependant on valve size and temperature range of -50°F to 180°F); Nylon(Temperature rating -30°F to 200°F; PEEK(Temperature -70°F to 550°F); |

| Manufacturing process

|

Need grinding, hardening and other precision processing. High precision requirements, complex processing and long production cycle | Easy deformation, low processing accuracy, even free-processing |

| Medium

|

Hot water, gas, gas, oil, acid and alkali medium | Air, water and other non-corrosive media |

| Working pressure | Medium or high pressure above 3.5mpa | Medium or low pressure |

| Working temperature

|

Metal seated valves are suitable for temperature up to 540℃ (Higher based on the material of body and trim). | Soft seated ball valves are suitable for the working temperature lower than 260℃. Aging easily affected by temperature, used in room temperature environment. Fire protection is needed to prevent leakage at high temperatures. |

| Leakage class(Ball valve) | Class V and VI | VI |

| Cost & Price | Metal seat valve is much higher than soft seat valves | Cheaper than metal seat valves |

| Sealing performance | Wear resistance but easy to leak relatively poor sealing performance | Easy to wear and can achieve a high level of sealing performance or even zero leakage |

How to choose soft seated or metal seated ball valves?

When it comes to choosing between a metal or softseated ball valve, there are a few factors

to consider.

Firstly, it is important to understand the differences between the two types of valves. Metal-seated ball valves are typically made of materials like stainless steel or brass, and are designed

for use in high-temperature or high-pressure applications. Soft-seated ball valves, on the other hand, are made with materials like Teflon or other polymers,

and are better suited for lower-pressure applications.

When deciding between the two, youwill want to consider the specific application and the

conditions the valve will be exposed to. If you’re working with high temperatures or pressures,

a metal-seated valve may be the better choice. However, if you’re working with lower pressures

and want to minimize the risk of leaks or contamination, a soft-seated valve may be a better option.

Additionally, you’ll want to consider factors like cost, maintenance requirements, and the specific

materials being used in the valve. Ultimately, the decision will depend on your specific needs and

the conditions of your application.

JONLOO company supplies both soft seated and metal seated ball valves at good quality. If you need, pls send ur inquiry to [email protected].

Next: The Lining Material for Lined Valves

Previous: The Benefits of Fire Safe Valves