The top producers of industrial valves adhere to certain guidelines when producing these valves to guarantee their performance, longevity, and quality. Any inferior quality could result in unintended harm and financial losses. When selecting a valve from the many options available, two extremely important considerations are efficiency and ease of operation.

Examine it to learn more about gate valves, which are also known as sluice valves.

A Sluice Valve: What Is It?

A valve that uses a wedge-shaped or gate-shaped disk that moves perpendicular to the fluid flow into or out of the pipeline is known as a Sluice gate valve or gate valve. The disk of the gate valve is totally isolated from the flow when it is fully opened. This essentially provides no resistance to flow. As a result, the fluid experiences relatively little pressure loss when passing through the gate valve.

The most popular kind of valve used in process plants to manage slurries is the sluice gate valve. These valves can be entirely closed or fully opened when they are in operation.

Sluice gate valves are not suitable for throttling because they are not accurate enough. In addition to causing vibration and noise, the partially open valve's rapid flow velocity may erode the disk and seat surfaces.

Function of Sluice Valve

The sole purpose of a gate valve or sluice valve is to initiate or stop the flow. Sluice valves are utilized for slurries, and gate valves are used for the water delivery system. Lifting the gate or wedge away from the water flow opens the gate valve, letting all water run through without encountering any obstruction. The stem, which is the connecting rod/shaft, contains a hand wheel or motor at the top to raise and lower the gate, and a gated circular or wedge-shaped opening at the bottom to stop the flow of water. Because of its threaded stem, in order to prevent water hammer effects, the valve must turn many times from the open to the closed position.

Gate

The primary component of a gate valve is the gate, which comes in a variety of designs. For certain applications, its sealing capacity is its primary design feature. Depending on the type of gate, a gate valve can be categorized as parallel or wedge-shaped. There are three types of the former: parallel sliding, slab, and parallel expanding gates.

Seat

Two seats on a gate valve guarantee sealing when the gate is closed. These seats can be used as seat rings or integrated into the valve body. After being pressed or screwed into place, the latter is sealed and welded to the valve body. Seat rings are the recommended option when the valve is exposed to higher temperatures because they provide greater design flexibility.

Bonnet

Bonnets are parts of valves that guarantee the passage's secure closure. To enable removal for maintenance or replacement, it is either screwed or fastened to the valve body. Bolt bonnets, screw-in bonnets, union bonnets, and pressure seal bonnets are some examples of different valve bonnets based on application.

Rising and Non-Rising Stem Designs

Gate valve stems can be either rising or non-rising. When a valve is opened, it is said to be rising if the stem emerges from the valve bonnet.

Inclined Disc Designs

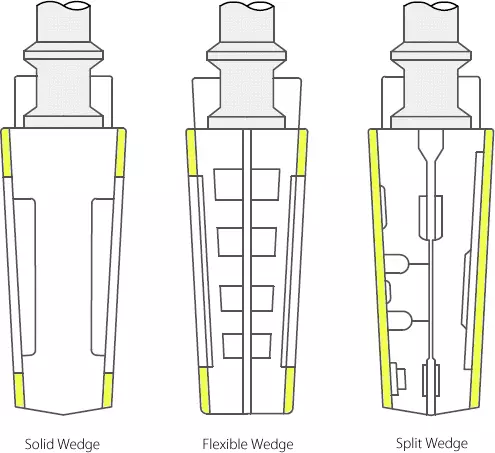

Solid Wedge Gate Valves

The most basic, robust, and appropriate wedges for a variety of flowing media are solid wedges. The disc seat area size of solid wedges is the same as the valve seat area size, and they are frequently made from a single metal piece.

Gate Valves with a Flexible Wedge

To make it easier for the disc to find the sitting surface, flexible wedges are machined around the circumference of the wedge. A larger machined area will weaken the disc since a thinner disc has less strength.

Gate Valves with Split Wedge Design

Flexible seating is available on the suction and discharge sides of split wedges. Due to the flexibility that results from employing two different halves for a single wedge, the wedge is made up of two separate parts that can each self-align to sit correctly.

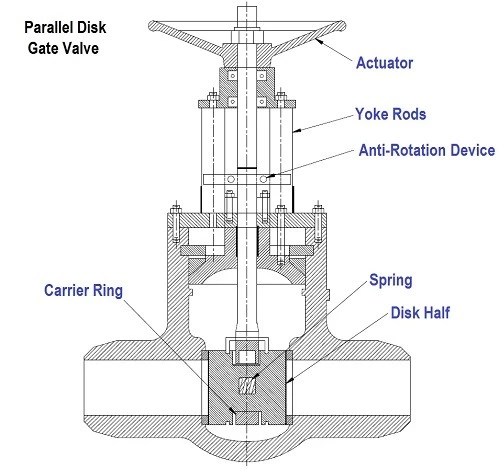

Gate valves with Parallel Disc

A spring is positioned in between the two parallel discs in a parallel sliding disc. Because the spring is compressed between the parallel discs, it continuously pushes outward onto the discs' inside surfaces. The spring compresses more as the valve is lowered into the valve seat, and the force it exerts as a result guarantees that each disc is firmly pressed against the seat.

The usage and operation of gate valves and sluice valves differ slightly. For sludge applications and in-line sealing, a gate valve may be a suitable choice. However, the best choice for your application is a sluice gate valve when it comes to controlling the flow in a sluice or stream.