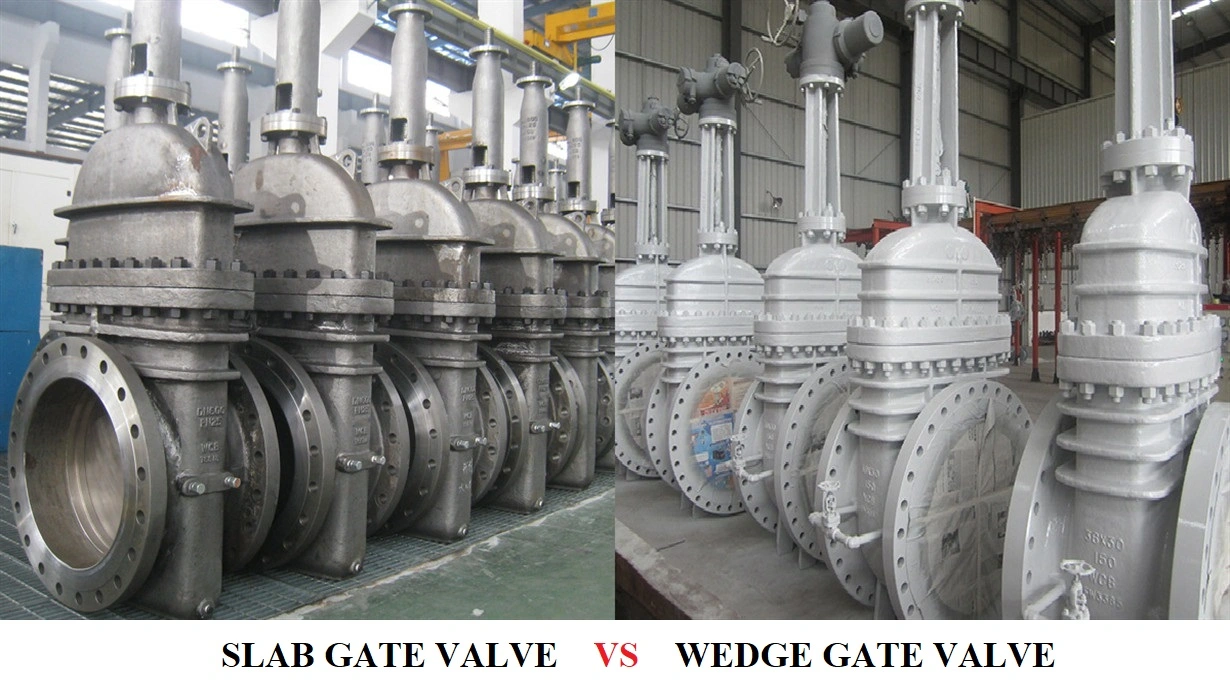

Slab gate valve and wedge gate valves are all designed for use in power, oil and gas industry applications. They are the main and commonly used types of gate valves. They have the similar structure form the appearance, when fully open, they do not have a bore through the gate itself and the gate retracts into the valve body, saves height space that is necessary for slab and expanding gate valves. Today here we will introduce the difference between slab and wedge type gate valve.

Slab Gate Valve

Slab gate valves are comprised of a single gate unit which raises and lowers between two seat rings. Due to the fact that the gate slides between the seats, slab gate valves are suitable for the medium with suspended particles. The sealing surface of slab gate valves is virtually self-positioned and is not damaged by the thermal deformation of the body. Even if the valve is closed in a cold state, the hot elongation of the stem does not overload the sealing surface, and slab gate valves without diversion holes do not require high precision in the closing position of the gate. When the valve is fully open, the bore through is smooth and linear, the flow resistance coefficient is minimal, piggable and no pressure loss.

The slab gate valve is a sliding valve whose closing part is a parallel wedge. The closing part can be a single valve disc or a double valve disc with a supporting mechanism between them. Single or double-disc slab gate valves are suitable for oil and gas pipelines with DN50-DN300, class150-900 / PN1.0-16.0 Mpa, operating temperature -29 ~ 121℃. In the case of pipeline with piggable design, use a rising stem gate valve with a diversion hole. The slab gate valve with a diversion hole with a dark rod floating seat is suitable for oil and gas recovery wellhead device. The product oil pipeline and storage equipment shall use a single gate or double gate flat gate valves without diversion holes.

Features of Butt Welded Slab Gate Valves and Flanged Slab Gate Valves

A slab gate valve can have butt welded ends or flanged ends. What are the characteristics of them? You can find the answers from below.

Features of Butt Welded Slab gate valves

1. Small fluid resistance and small scouring and erosion of sealing surface by medium

2. Easy opening and closing

3. Not restricted medium flow direction

4. Simple shapes, short structure length, good manufacturing processes and wide application ranges

Features of Flanged Slab gate valves

1. The valve seat sealing structure of the flanged slab gate valve is elastic with preload, and the upstream and downstream sealing valve seats are sealed at the same time. The valve seat and seal are face-to-face sealed.

2. The valve seat has self-cleaning function and is not directly scoured by the air flow during the opening or closing of the valve. The valve seat is made of lubricated and non-abrasive materials.

3. The failure of the valve actuator will not affect other parts of the valve, and it can be repaired and replaced without removing the valve.

4. When the flanged slab gate valve is fully opened, the channel is smooth and straight; the flow resistance coefficient is extremely small, and there is no pressure loss.

The slab gate valve adopts the packing with self sealing, which has reliable sealing performance and truly achieves zero leakage. It solves the problem of easy leakage at the packing of the general valve.

Wedge gate valves are comprised of a tapered gate that is metal-to-metal sealing. Compared with a slab gate valve, wedge gate valves are not piggable because of the void that is left in the bottom of the valve body when the valve is open. The wedge design increases the auxiliary sealing load, enabling metal sealed wedge valves to seal at both high and low medium pressures. However, wedge gate valves with metal seals are often unable to achieve the inlet seal due to the specific pressure of the inlet seal caused by the wedge action. Wedge gate valves have a certain Angle, generally, 3 degrees or 5 degrees, resulting in accumulated material in the lower groove of the valve, the medium with the particulate matter may damage the sealed seat, make loose closure.

Wedge gate valve application

Wedge gate valves are generally used where has no strict requirements of the size of the valve and harsh occasion. Such as high temperature and high pressure working medium, the requirements to ensure the closure of the long – term sealing conditions. Normally, for the environment with reliable sealed performance, high pressure, high-pressure cut-off (differential pressure) and low pressure by the (small) differential pressure, low noise, have spirit point and evaporation phenomena, the high temperature, low temperature, cryogenic medium, it is recommended to use wedge gate valve such as the electric power industry, oil refining, petrochemical, offshore oil, tap water and wastewater treatment engineering of urban construction, chemical industry, etc.