The ball valve realizes the opening and closing of the valve when the sphere rotates around the axis of the valve stem at an angle of 90. It is mainly used for cutting, distributing and changing the flow direction of the medium on the pipeline. The ball valve has simple structure, good sealing performance, small sizes, light weights, low material consumption, and small installation size within a certain nominal size range. The ball valve has small driving torque, simple operation, rapid opening and closing and remote control, and is one of the fastest-growing valve varieties in the past ten years.

According to the sealing material, the ball valve is divided into non-metallic sealed ball valve and metal sealed ball valve. The non-metallic sealed ball valve’s sealing pair is made of non-metallic materials, which is easy to achieve sealing and has already become a mature product. The sealing pair of the metal-sealed ball valve is made of metal, which has a wider application range in the field of temperatures and fluid media and is widely used in harsh working conditions. The sealing performance of metal is difficult to reach the level of non-metallic materials, especially under high pressure or high temperatures, the elastic deformation of the ball and valve seat of the metal sealed ball valve cannot be avoided, and the sealing failure caused by elastic deformation is difficult to predict in the design stage.

2. The principle of sealing

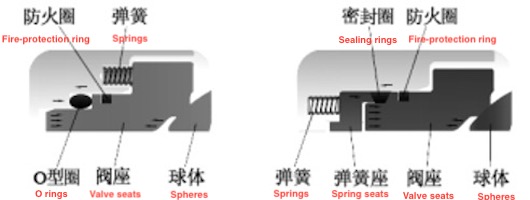

The sphere of the trunnion ball valve is fixed on the upper and lower shafts or the support plate, and the floating valve seat is adopted. Under the combined action of the spring force and the medium pressure, the sealing surface of the metal valve seat by precision grinding is attached to the spherical surface to achieve the purpose of sealing. Figure 1 shows a partially enlarged view of the sealing part of the seat of the trunnion ball valve. When the valve is in the closed state, the fluid is cut off by the graphite sealing ring or the O-ring. At this time, the valve seat is subjected to the spring preload force F, the medium force G generated by the fluid pressure P, the friction force f of the sealing ring and the reacting force of the sphere to the valve. The sealing force that acts as a sealing force is the resultant force to the right (F+G-f). Sealing is achieved when the sealing specific pressure generated by the sealing force is greater than the necessary specific pressure for sealing.

Figure 1 The structure diagram of a typical metal-sealed trunnion ball valve seat

3. The analysis of the cause of leakages

Through the analysis of the sealing principle, the main reasons for the leakage of the metal-sealed trunnion ball valve are as follows:

(1) O rings or graphite sealing rings leak.

(2) The degree of grinding between the sealing surface of the valve seat and the spherical surface is not enough, and the sealing pair does not match.

(3) The sphere is not round, or the sealing surface is rough.

(4) Insufficient strength of spheres, valve seats and fixed shafts causes plastic deformation.

(5) The elastic deformation of the ball and valve seat under the medium’s pressure causes the sealing pair to peel off.

For the first four causes of leakages, the general manufacturers have experience in dealing with them, and it is relatively easy to solve them. However, the fifth cause of leakages is not easy to discover, especially under high pressure or high temperatures. There is a good effect when the low-pressure gas sealing test is performed. The higher the pressure is, the greater the leakage becomes. However, when the pressure is released, the sphere and valve seat return to the original state, and the roundness of the sphere and the fit of the sealing surface are all qualified. In this case, it is usually presumed that the O ring or graphite ring on the back of the valve seat leaks, and the asynchronous elastic deformation of the ball and the valve seat under high pressure or high temperatures is often ignored, resulting in the peeling of the sealing surface. The elastic deformation is complex, and the deformation amount of different parts is different, so it cannot be directly calculated. Generally, it needs to be analyzed and verified by means of computer finite element simulation. Taking NPS2-CL2500 metal-sealed trunnion ball valves as an example, the main parameters are as follows:

Materials of spheres: F304+NI60

Materials of valve seats: F304+NI55

Diameters of spheres: φ90mm

Diameters of passageway: φ42mm

Inner diameters of sealing surfaces: φ54mm

Outer diameters of sealing surfaces: φ62mm

The outer diameter of the valve seat under the force of the medium: φ68mm

The outer diameter of small steps of valve seats: φ58.6mm

The outer diameter of large steps of valve seats: φ88mm

Spring force: 1100N