bolted design. With the bolted body design, as pressure increases the gasket sealing force reduces, allowing the possibility of a potential leak point.

Whereas with the pressure seal design, increasing fluid pressure increases the gasket sealing force.

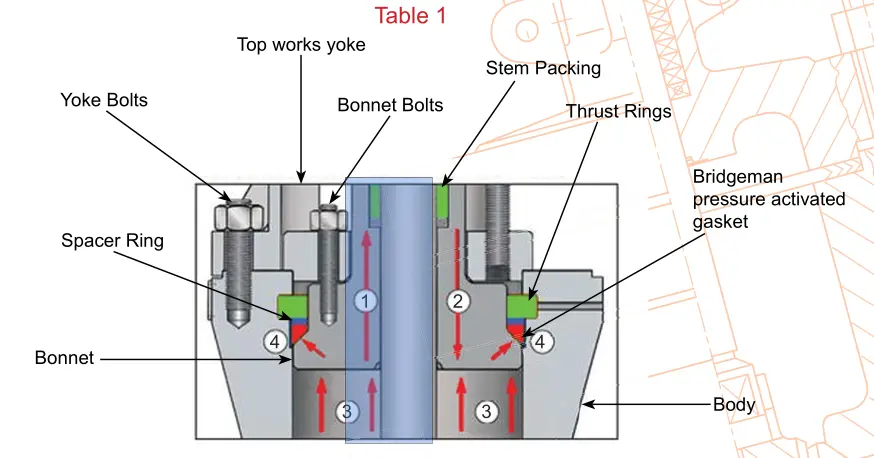

The Bonnet bolts effect a seal on the pressure seal joint which forces the bonnet onto the ‘bridgeman’ soft metallic gasket which in turn is forced up

hard against the outer body. Refer table 1 below. The higher the line pressure, the higher the sealing force against the gasket, further tightening the seal.

The thrust rings are embedded in the body. In smaller forged valves sometimes a ‘breech-lock’ threaded bonnet insert is used instead of a bolt energised

bonnet. Pressure seal bonnets are superior to traditional bolted bonnets and are ideal for high pressures and situations in power plants and refi neries

where frequent pressure surges, start-ups and shut-downs occur.

The bonnet gasket is metallic. A ‘bridgeman’ gasket is used as its design ensures that pressure acting against it further increases the seal against the

surface effecting a self-energised seal. In larger sizes this gasket is silver plated as silver provides a softer surface to flow the gasket metal into the

mating flange surface. Flexible custom made expanded graphite gaskets are also available. Another superior option for larger sizes is 316 + Graphite

gasket. In very large sizes graphite gaskets can be specifi ed in conjunction with live loading bonnet bolt washers that can be tightened to ensure a

constant force is applied to the bonnet gasket.

There are 3 different designs of pressure seal bonnet: - threaded locknut type (breech lock), bonnet take-up type (bolted yoke arm) and bolted type

shown below.

Some other key features of JONLOO pressure seal valves are as follows:

• No pressure retaining body/bonnet fl anges or bolting results in lighter weight design compared to bolted bonnet.

• Differential angle between bonnet and gasket, concentrates the gasket seal force for a better seal at gasket tip.

• Take-up plate and bolting creates initial gasket seal and ensures seal throughout the entire range of working pressures.

• Take-up plate is a separate piece from the yoke arm which allows removal of the yoke arm without disturbing pressure seal joint.

• JONLOO uses a metal gasket in it’s standard pressure seal design which is a stronger material with a longer lifetime and lower coeffi cient of thermal

expansion compared to softer gaskets

1/2 Bonnet can move up or down as pressure increases and decrease

3 Line Pressure

4 Line pressure further tightens Bridgeman gasket seal

Next: NI-ALUMINIUM BRONZE butterfly valve

Previous: VALVE TYPES