There are many factors affecting the sealing of valves. There are mainly the following points.

1. Auxiliary structure of the sealing

Under the change of temperature or sealing force, the structure of sealing pair will change. And this change will affect and change the force between the sealing pair, so that the performance of the valve seal is reduced. Therefore, when choosing seals, we must choose seals with elastic deformation. Also, we should pay attention to the width of the sealing surface. The reason is that the contact surface of the sealing pair cannot be completely matched. When the width of the sealing surface increases, the force required by the sealing shall be increased.

2. Sealing surface ratio pressure

The specific pressure of sealing surface affects the sealing performance of valves and the service life of valves. Therefore, the sealing surface specific pressure is also a very important factor. Under the same conditions, too much specific pressure will cause damage to the valve, however too little specific pressure will cause leakage of the valve. Therefore, we need to give full consideration to the fitness of the specific pressure in the design.

3. The physical properties of the medium

The physical properties of the medium also affect the sealing performance of valves. These physical properties include temperature, viscosity and surface hydrophobicity. The temperature change does not only affect the relaxation degree of sealing pair and the change of parts size, but also has an inseparable relationship with the viscosity of gas. The viscosity of a gas increases or decreases with increasing or decreasing temperature. Therefore, in order to reduce the temperature of the valve sealing performance of the degree of influence, we are in the sealing design to design the elastic seat and other heat compensation valve. Viscosity is related to the permeability of a fluid. Under the same conditions, the greater the viscosity, the less the permeability of the fluid. The surface hydrophilicity refers to the removal of a thin film on the metal surface. Because this thin film of oil breaks the hydrophilicity of the surface, it blocks the passage of the fluid.

4. The quality of the sealing pair

The sealing deputy quality mainly refers to the selection of materials, matching and manufacturing accuracy. For example, the disc and seat sealing surface are very consistent. It can improve the sealing of valves. The characteristic of annular waviness is that its labyrinth sealing performance is good.

The valve leakage is common in life and production. Light can cause waste, or bring danger to life, such as tap water valve leak, or causing serious consequences, like chemical industry of poisonous and harmful, inflammable, explosive and corrosive medium leakage in nature. It will be a serious threat to personal safety and property safety, and environmental pollution accidents. A valve that depends on external rotating transmission to open and close is designed with a sealing device, which is used to install a certain number of packing rings in the packing culvert, so as to achieve the sealing effect. However, how is the valves sealing situation? The leakage of valves packing is one of the most prone parts of the valve leakage failure.

The seal form of valves

The seals are also key components in valves. The sealing performance of the valve refers to the ability of sealing parts of the valve to prevent media leakage, which is the most important technical performance index of the valve.

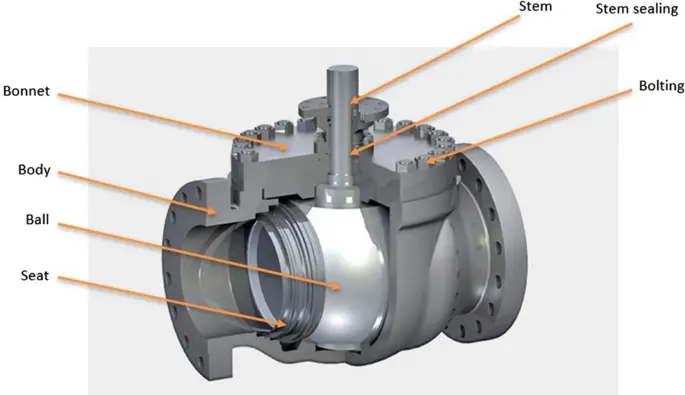

There are three sealing parts of the valve.

1. The contact between the opening and closing parts and the sealing surface of the valve seat

2. Packing and valve stem and packing box matching place

3. Joint of body to bonnet

One of the former leakages is called internal leakage, which is usually said to be lax. It will affect the ability of the valve to cut off the medium. For the block valve class, internal leakage is not allowed. The latter two leakage is called external leakage, that is, media leakage from the valve to the valve outside.

The leakage will cause material loss, pollution of the environment, even accidents. For flammable, explosive, toxic or radioactive media, the leakage is not allowed. Therefore, the valve must have reliable sealing performance.