Ball valves are crucial for managing the flow of gases and liquids in industrial pipe systems.

Because of their unique designs and uses, long-pattern and short-pattern ball valves stand out among the other variations.

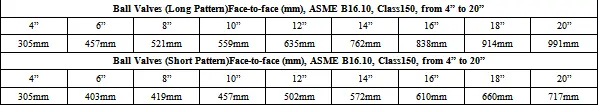

These phrases relate to the valve's body length as defined by ASME B16.10 and other standards that regulate the valve's face-to-face and end-to-end dimensions.

Knowing how long pattern and short pattern ball valves differ from one another will help you make wise decisions, whether you're looking to maximize space in a small installation or give longevity and flow efficiency top priority.

Compared to its short-pattern counterpart, a long-pattern ball valve has a longer body design and larger face-to-face dimensions. This kind of valve is designed to withstand demanding industrial uses.

- Longer Length: The longer valve body offers a stronger construction.

- Flow Efficiency: The interior passage's longer length usually results in a smoother, more steady flow with less turbulence.

- Standard Compliance: ASME B16.10 is frequently followed in the manufacturing of long pattern ball valves, guaranteeing consistent dimensions throughout industries.

- High-Pressure Systems: These valves are perfect for high-pressure pipes because of their robust design.

- Refineries and Petrochemicals: Because of their sturdy design, long pattern valves are frequently utilized in oil refineries.

- Corrosive Environments: These valves are resistant to severe chemicals when made of the right materials.

Because of its small body shape, a short pattern ball valve is lighter and simpler to install in confined locations. When space is a major factor, this style is frequently employed.

- Compact Size: The valve's footprint is reduced by its shorter face-to-face length.

- Cost Effectiveness: Short pattern valves are more cost-effective since they typically use less material.

- Fast Installation: Because of their compact size, they are easier to install and maintain, particularly in tight spaces.

- Tight Spaces: Perfect for systems with little room, like modest processing units or shipyards.

- Systems for Moderate Flow: Ideal for pipelines requiring a moderate amount of pressure and flow.

- Temporary Installations: These are frequently utilized in settings that require repeated relocations or replacements.

| Feature | Long Pattern Ball Valve | Short Pattern Ball Valve |

| Size and Length | Longer face-to-face dimensions | Compact and lightweight |

| Flow Characteristics | Superior flow efficiency with minimal loss | Moderate flow efficiency |

| Cost and Space | Higher cost, occupies more space | Cost-effective, space-saving design |

| Pressure and Temperature Handling | Suitable for high-pressure, high-temperature systems | Best for moderate pressure and temperature conditions |

Because of their longer bodies, long pattern valves weigh more and take up more space. Because they are smaller, short-pattern valves are perfect for installations in tight spaces.

Smoother and more reliable flow is made possible by long pattern valves' longer interior path. Short pattern valves are adequate for typical flow conditions, albeit they may result in a little extra turbulence.

Because they require more material and are greater in size, long pattern valves are more expensive. Because they are smaller and lighter, short pattern valves are more affordable.

Short-pattern valves are made for moderate operating conditions, whereas long-pattern valves perform well in high-pressure and high-temperature settings.

In order to guarantee system compatibility, ASME B16.10 specifies the dimensions for face-to-face and end-to-end measurements in valves.

These standards are followed by both long and short-pattern ball valves, allowing engineers to create systems with reliable and uniform specifications.

In addition to making replacement easier, this standardization guarantees that valves fulfill the temperature and pressure requirements for the applications for which they are designed.

- High-Duty Operations: For systems like gas and oil pipelines that need to be extremely dependable and durable, choose lengthy pattern valves.

- Corrosive Media:They are appropriate for chemical and corrosive conditions due to their sturdy design and variety of material possibilities.

- High Pressure: To guarantee long-term performance, select these valves for pipelines that operate at high pressure.

- Space-Constrained Installations: Perfect for small spaces with limited room, such shipyards and machinery.

- Cost-Sensitive Projects: Due to their affordability, these valves are appropriate for applications with limited funds.

- Frequent Maintenance: In systems that need regular maintenance, their reduced size makes it simpler to replace or maintain them.

Selecting the appropriate valve for your system and industry as a whole requires an understanding of the distinctions between long-pattern and short-pattern ball valves.

Long-pattern valves are perfect for high-pressure industrial applications because of their exceptional longevity and flow efficiency.

Conversely, short pattern valves are small, affordable, and appropriate for installations with constrained space.

By considering variables like temperature, pressure, and available space, you can make an informed decision to maximize the performance of your piping system.