When it comes to industrial system management, efficiency and safety are unavoidable. On a factory floor, for example, a single inadvertent valve adjustment could result in an expensive shutdown or, worse, a safety risk.

Lockable ball valves provide a dependable way to stop tampering and guarantee regulated fluid flow in this situation. However, what makes these valves essential?

We'll examine the construction, operation, and various uses of locking ball valves in this guide, emphasizing its significance for leak prevention and industrial safety.

Let's examine how these cutting-edge valves can improve the operation of your system, starting with an awareness of their benefits and operating mechanics.

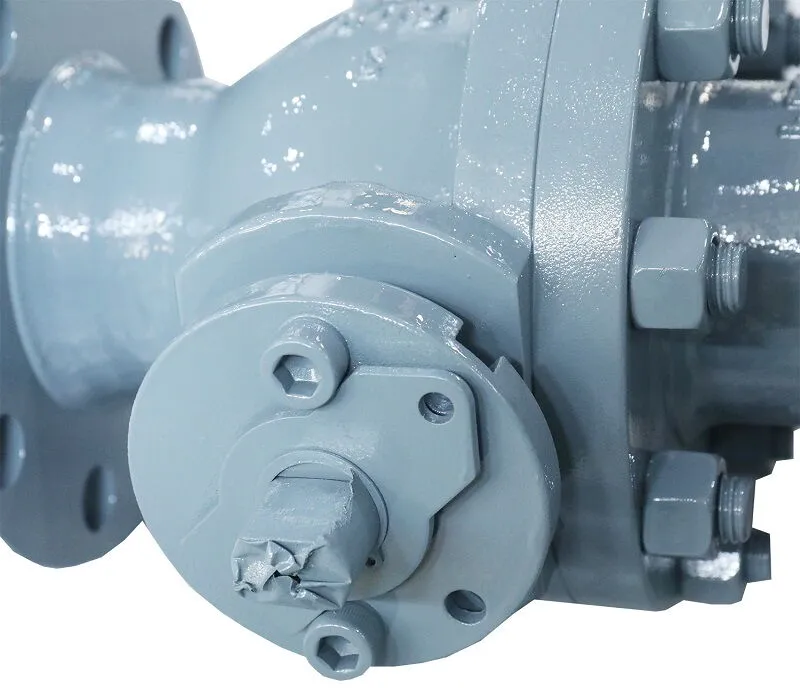

A specific kind of ball valve with a locking mechanism to maintain its position is called a lockable ball valve.

This guarantees that unless authorized people purposefully alter the valve, it will stay in an open or closed state.

For improved control and security in industrial systems, the locking feature can be introduced as an external device or integrated as a built-in mechanism.

In industries where exact control over fluid flow is crucial and where unintentional or unauthorized alterations could result in dangerous situations or expensive damages, these valves are extensively used.

Ball valves that lock provide protection against tampering and human mistake. In sectors like manufacturing, chemicals, and oil & gas, even a small change in valve settings can cause operational disruptions or safety hazards.

Businesses can use a ball valve lock to:

- Prevent illegal access: The valve can only be adjusted by staff who have the necessary tools or keys.

- Boost security at work: Lowering the possibility of unintentional valve operation reduces the amount of hazardous substance exposure.

- Ensure system integrity: Leaks are less likely when system pressure and fluid flow are maintained as intended by secured valves.

It is simple but efficient to use a locking ball valve.

Locking mechanisms, such as padlocks or key locks, are installed on the handle or lever of the valve. The lock keeps the handle from moving while it is engaged, so locking the valve in place.

Certain designs allow for both open and closed lock applications, providing operational flexibility without sacrificing security.

In addition to locking ball valves, valve locking devices are crucial parts. These devices meet various operational requirements and fluid kinds. Here are a few typical kinds:

Pneumatic systems are the intended use for air valve locks. They guarantee regulated airflow and stop unintentional leaks that can damage equipment or present safety risks.

Water valve locks, which are frequently seen in industrial cooling systems, municipal water lines, and plumbing, secure water supply systems. They guarantee reliable operation and aid in preventing excessive water use.

In gas distribution systems, gas valve locks are essential for stopping tampering or unintentional leakage. Gas lines in homes, businesses, and industries frequently use them.

The flow of hydraulic fluids in large machinery and equipment is managed by hydraulic lock valves. Leak prevention and system pressure maintenance depend on these locks.

Locking ball valves are versatile and find applications in various industries, including:

- Oil and Gas: protecting pipelines and stopping interference with vital processes.

- Chemical Processing: ensuring the safe handling of dangerous substances through precise flow control.

- Water Treatment: preventing unapproved modifications to industrial and municipal water systems.

- HVAC Systems: regulating the flow of fluids in air conditioning, heating, and ventilation systems.

- Food and Beverage: ensuring that fluid transfer in production lines is controlled and sanitary.

Locking ball valves are essential in industrial systems because of their many advantages:

- Enhanced Safety: Prevents unintentional operation and guarantees adherence to safety regulations.

- Leak Prevention: Lowers the possibility of leaks brought on by unapproved changes.

- Operational Control: Enables accurate flow control and system stability.

- Versatility: Ideal for working with a variety of fluids, such as liquids, gases, and slurries.

- Cost-Effective: Ensures dependable functioning, which reduces maintenance expenses and downtime.

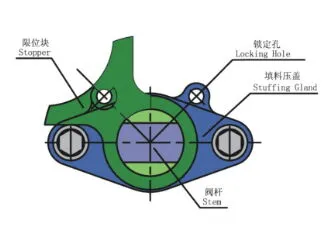

By incorporating cutting-edge technologies to stop unwanted or unintentional valve action, the locking ball valve design prioritizes safety and operational integrity.

Both the completely open and fully closed positions include carefully positioned locking holes in the design.

This function makes sure the valve stays firmly closed, preventing accidental movement brought on by external circumstances or abuse by unauthorized individuals.

Additionally, the locking mechanism takes into consideration the possibility of improper handling during outdoor installations or strong vibrations that may otherwise cause an unintentional valve operation.

In high-stress industrial settings, the system's inclusion of a stopper and locking pin improves longevity and dependability.

The main elements of the locking ball valve design are highlighted in the following image:

- Locking Holes: Enable secure locking in open or closed positions.

- Stopper: Prevents handle misalignment and ensures positional accuracy.

- Stuffing Gland: Reinforces sealing to prevent leaks under high pressure or vibration conditions.

In many different sectors, lockable ball valves are essential for improving safety, stopping leaks, and maintaining operational control.

These valves offer a dependable way to control fluid flow in intricate systems by incorporating strong locking mechanisms.

Whether it’s securing pipelines, preventing tampering, or maintaining system integrity, locking ball valves is a crucial asset in industrial safety and efficiency.

To protect your operations and maximize performance, pick the best locking ball valve for your requirements.