API 6A gate valve refers to a type of valve that conforms to the standards set by the American Petroleum Institute (API)

in their specification 6A. This specification outlines the requirements for wellhead and Christmas tree equipment used in

the oil and gas industry.

A gate valve is a type of valve that controls the flow of fluid by using a gate or wedge-shaped disc that moves up and down

to either block or allow the passage of fluid. API 6A gate valves are specifically designed for high-pressure and high-temperature applications, typically found in wellhead and production systems.

These valves are built to withstand harsh operating conditions and are commonly used in oil and gas exploration, drilling,

production, and refining processes. They are known for their robust construction, reliable performance, and ability to

handle corrosive fluids and extreme pressure differentials.

API 6A gate valves are typically made from durable materials such as carbon steel, stainless steel, or alloy steel, and

they come in various sizes and pressure ratings to meet specific industry requirements. They play a vital role in maintaining

the safety and efficiency of oil and gas operations by providing reliable shut-off control for fluid flow.

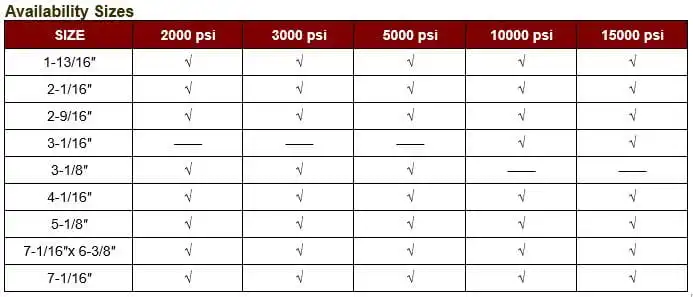

What sizes are for API6A Gate valve

The valve size for an API 6A gate valve can vary depending on the specific requirements of the application. The valve size is typically indicated by the nominal diameter, which can range from as small as 1 13/16 inches to as large

as 30 inches or more. The appropriate valve size is determined based on factors such as the flow rate, pressure, and other

operational parameters of the system.

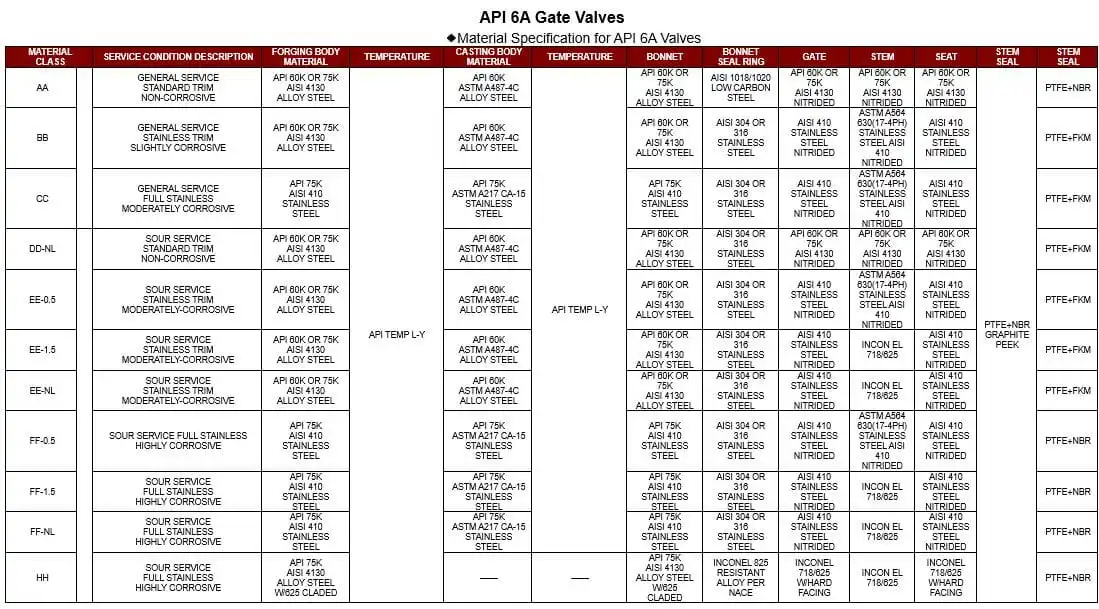

What is the material specification for API6A gate valve

The valve material for API 6A gate valves can vary depending on the specific requirements and applications. The material selection for the valve body, bonnet, and gate typically depends on factors such as pressure rating,

temperature, corrosion resistance, and the medium being handled.

Common valve materials used for API 6A gate valves include carbon steel, stainless steel, alloy steel, and duplex

stainless steel. Carbon steel (such as ASTM A105) is commonly used for lower pressure applications, while stainless steel (such as ASTM A351 CF8M or CF8) is preferred for higher-pressure and corrosive environments. Alloy steels (such as ASTM A217) and duplex stainless steels (such as ASTM A890)

may be used for more demanding conditions.

It's important to consult the specific API 6A valve manufacturer or supplier for the recommended valve material based

on your application requirements.

What is the difference between API6A gate valves and other gate valves

API 6A gate valves are specifically designed for use in the oil and gas industry, particularly in wellhead and Christmas

tree applications. These valves are built to withstand high pressures and harsh operating conditions.

The main difference between API 6A gate valves and other types of gate valves lies in their compliance with the API 6A

specification. This specification sets the standards for design, materials, testing, and documentation for valves used in

wellhead and Christmas tree equipment.

API 6A gate valves are typically larger in size and have higher pressure ratings compared to standard gate valves. They

are designed to handle extreme pressures and temperatures encountered in oil and gas operations. These valves are

often made from high quality materials such as carbon steel, stainless steel, or alloy steel to ensure durability and

resistance to corrosion.

Moreover, API 6A gate valves often feature metal-to-metal sealing surfaces, which provide a tight seal even in

high-pressure environments. They also incorporate a rising stem design, allowing visual indication of the valve's position.

In summary, the key differences between API 6A gate valves and other gate valves are their compliance with the API

6A specification, their ability to handle high pressures and temperatures, and their robust construction for use in oil

and gas applications.