Double Block and Bleed Systems

The primary function of a double block and bleed system is for isolation and the secondary function is for intervention.

Under certain conditions double block and bleed systems are needed to prevent product contamination or where it is necessary to remove essential equipment from service for cleaning or repairs while the unit continues in operation.

Of course, such equipment must be provided with a spare or it must be possible to bypass it temporarily without shutting down the unit.

The nature of the fluid, its pressure and temperature, and many other factors must be considered when determining the need for double block and bleed systems.

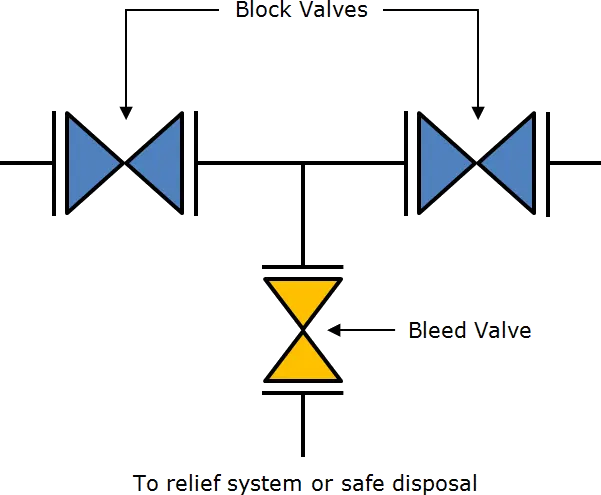

Generally, block Valves should be considered for the onstream isolation of equipment if the fluid is flammable or otherwise hazardous, or if the fluid is in high-pressure or high-temperature service. Where double block Valves are used, a NPS 3/4 or larger bleed Valve should be installed between the block Valves.

The purpose of the bleed Valve is twofold. First, the bleed ensures that the upstream Valve is in fact tight before slipping in a blind off the downstream block Valve. The bleed connection also permits the safe withdrawal of moderate leakage from the upstream Valve to again assure the tight shutoff of the downstream Valve.

Depending on the service conditions, it may be possible to use a single block Valve with a body bleed to provide double block and bleed provisions for onstream isolation of equipment.

Gate Valves with flexible wedges and with body or Bonnet bleed Valve can serve this purpose if specifically tested in accordance with API-598 for double block and bleed quality Valves.

Some Ball Valves and nonlubricated Plug Valves, when equipped with a Valve body bleed between the seats, can also be satisfactory substitutes for double block Valves.

Testing for double block and bleed quality Valves requires the pressure-testing of each seat, with leakage measured through the Valve body bleed as a means of substantiating the independent leak tightness of both the upstream and downstream seats of the Valve.

Double Block and Bleed Valves

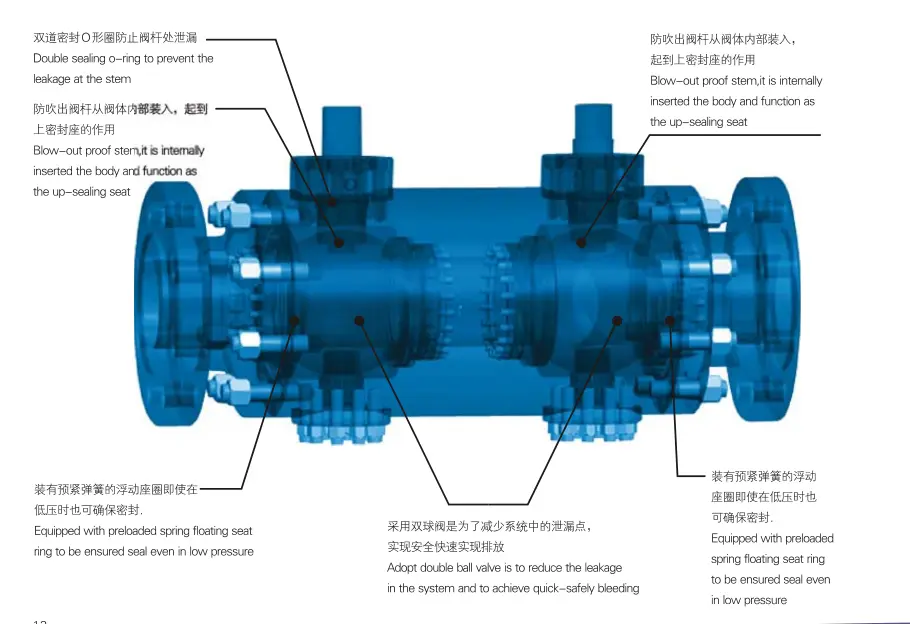

The Double Block and Bleed Valve or a DBBV can perform the tasks of 3 separate Valves (2 separate isolations and 1 drain Valve) which apart from being hugely space saving can also save on weight and time due to installation and maintenance practices requiring much less work and the operator being able to locate and operate all 3 Valves in one location.

Double block and bleed Valves operate on the principle that isolation can be achieved from both the upstream and downstream process flow / pressures.

This is achieved by two ball, gate, globe, needle, etc. Valves placed back to back, with a third "isolatable" Valve in the centre cavity.

Once isolation has been achieved in one or more of the main process isolation Valves, the cavity that is created between these isolations can be drained. This is useful for flow diverting, sampling or injection situations, and for maintenance and or integrity check situations where seat leakage can be monitored through the third "bleed" Valve.