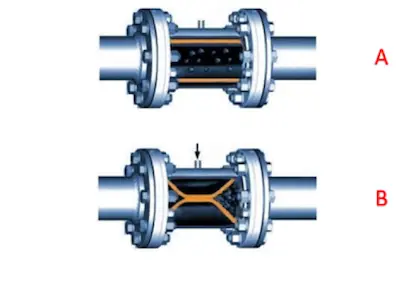

A pinch valve is a 2/2-way valve designed to shut-off or control the flow of corrosive, abrasive or granular media. It utilizes pressurized air to open or close the valve. In the open position, the valve has no restrictions and allows a wide range of media to pass through the bore. The flexible internal rubber sleeve in the valve keeps the media isolated preventing the risk of contamination. Figure 1 is an example of a pneumatic pinch valve.

Pinch valves are ideally suited for use with slurries and granular products like sand, cement, gravel, textile fiber, carbon, powder, pellets, chipping, glass fragments, etc. These valves are cost effective, reliable and easy to use, making them desirable in a wide range of industrial applications.

How does a pinch valve work?

A pinch valve consists of three major components: a housing, an internal rubber sleeve (orange section in Figure 2) and end connections. The rubber sleeve is fitted into the housing from inlet to outlet and is the only component that comes in contact with the media. The end connections are bolted, screwed or threaded at each end to provide support and connection to the valve. The valve is open in a normal position (un-pressurized) as seen in Figure 2.A. When the pressurized air is applied to the valve, it pushes down the rubber sleeve, creating a pinching effect as seen in Figure 2.B. When the rubber sleeve is completely pinched, the flow is obstructed, and the valve is closed. Unlike the conventional valves like ball or gate valves where particles can get trapped around the ball or discs, the rubber sleeve in a pinch valve is able to trap the particles around it, providing an excellent shut off. When the external air pressure is no longer applied to the rubber sleeve, the elastic rebounding property of it along with the force of the flowing media fully opens the valve. The fully opened valve provides free flow passage to the media preventing the valve from clogging or blockage. The media also only comes into contact with the rubber sleeve, allowing the media to be isolated, no contamination, and no damage any other components.

Figure 2: Operating principle of a pinch valve: Open position (A) and Closed Position (B)

When the abrasive media strikes the rubber sleeve, it absorbs the impact and deflects it back to the media. This resilient property helps the rubber sleeve wear at a much slower rate and gives it a longer service life than metal surfaces.

Advantages

A pinch valve has a unique design, which provides it with the following advantages:

- Great to use with abrasive and corrosive media

- Straight flow path and no clogging by the media

- Minimum turbulence and friction

- Keeps media free from contamination

- Easy replacement of the rubber sleeves and a low maintenance cost

- Excellent sealing properties

- Quick opening and closing time

- Low energy consumption

Disadvantages

The few disadvantages of pinch valves are:

- Due to elastomeric property of the sleeve, the valve is not suitable for high temperature application.

- High pressure differential can cause the rubber sleeve to collapse or deform causing the valve to not open fully.

- The valve is not suitable for vacuum applications as suction inside the valve may lead the sleeve to collapse.

Selection criteria

Following criteria should be considered while selecting a pinch valve for your application:

- Material: The valve body material should be lightweight for easy handling, but it does not need to be compatible with the media since they do not come in contact. The rubber sleeve, however, should be given careful consideration because it is the only component that comes in contact with the media. The rubber sleeve material may include natural rubber, NBR (nitrile), EPDM (ethylene propylene diene monomer), silicon, food quality rubber, etc. The material should have good abrasion resistance to avoid damage by the media.

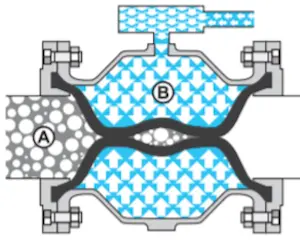

- Pressure: To prevent a failure to open/close, the following pressure differentials need to be taken into account:

- Opening:The operating pressure needs to be greater than the control pressure. Control pressure is typically 0 bar when opening. If the pressure differential is not big enough, the operating pressure will not be able to open the sleeve.

- Closing:The control pressure needs to be greater than the operating pressure. If the pressure differential is not big enough, the control pressure will not be able to overcome the operating pressure in pushing the sleeve in to close the valve.

Max Control Pressure = Operating Pressure + Max Pressure Differential

Figure 3: Pressure system in a pinch valve: Operating pressure (A) and control pressure (B)

2.Certification: Depending upon your application, certification may be required for safety and no contamination of the media (i.e. food grade, drinking water, etc.).

Field of application

Pinch valves are increasingly being used in industrial applications due to their advantages. Some of the industries using pinch valves include:

- Food and beverage industries

- Pharmaceutical industry

- Chemical industry

- Cement industry

- Bulk and solid handling industry

- Ceramic industry

- Plastic industry

- Wastewater industry

Next: RTK Control Valve

Previous: Knife gate and slurry valves