What's the deal with well-performing valves? What is it that makes them perform better? Are the materials the cause? Do the calibrating machines really make a difference? In actuality, each of these matters. It is necessary to have more knowledge about the manufacturing process of valves before delving into the intricate features of the industrial valve.

The entire process of making industrial valves will be covered in this article. Readers would learn more about the production and processing of valves from this.

1. Order and Design

Initially, the client needs to place an order, be it for a specially made valve or something from the list of pre-made valve designs. When a customer requests a personalized one, the business presents a design to them. The sales person places an order after receiving approval from the latter. Additionally, the customer gives the business a certain deposit.

2. Inventory

The manufacturing department will search for the raw materials for the stem, spool, body, and bonnet once order placement and design are underway. The manufacturing department will purchase materials from suppliers if there are not enough of them.3. Completing the Checklist

The manufacturing crew reviews the list once more to make sure everything is there after the materials are all delivered. Additionally, this is the time that the design's final draft is approved. The quality assurance team also extensively inspects the materials. This is to guarantee the highest caliber of raw resources.4. Production Process

This includes most of the tasks involved in the production process of industrial valves. Every significant component is created separately. Frequently, a checklist with all the names of the replacement parts and the appropriate material is present.At this point, the team leader gives a schedule for the real manufacturing, including the steps involved from the beginning to the end. Furthermore, the leader frequently creates a thorough operational plan.

The two typical manufacturing processes for valves are covered below.

#1: Cast Method

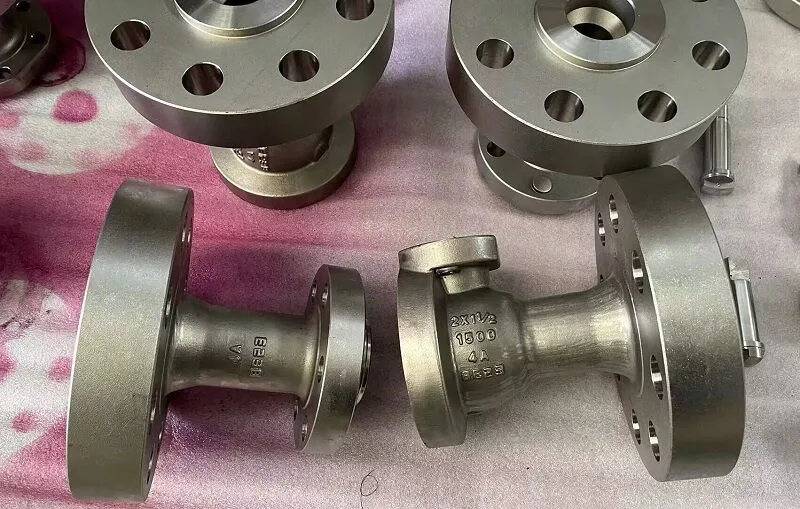

An overview of the cast procedure can be found in the following illustration. Keep in mind that this is not the entire procedure.

● Body:

A previously formed, cleansed substance. After cleaning, a turning procedure is carried out. Turning is the process of cutting away extra material with a lathe or turning equipment. The pre-shaped body must be fastened to the turning machine and a mount. This machine has a rapid rate of rotation. A single-point cutter shapes the body into the precise shape while it rotates. In addition, turning can produce holes and grooves, among other things.

The next stage is to plate various bodily parts with a metal, usually copper. The body is properly and completely sealed thanks to the copper plating.

The body needs to be polished next. The threads needed to attach specific valve pieces to other parts or pipes are then made by technicians. Holing occurs after this because valves require holes. Be aware that, depending on the need, the hole sizes in each valve vary. Standards and rules are relevant in this situation.

After that, technicians apply Teflon or another kind of elastomer to the valves. There's painting, then baking. By baking, Teflon forms a link with the human body.

● Seat

The body goes through the same process as the seat. Because the seat is inside the body, it must fit perfectly to its attachment in order for the valve to function properly and provide superior sealing. The seat includes an additional rubber wrapping to provide snug fit, while the body is solely made of Teflon.● Stem

Just like with the stem, not a lot of production is required. It's crucial to cut these to the proper dimensions instead.#2: Forged Method

This procedure below provides a summary of the forged approach. Likewise, the following procedure just illustrates the nature of the falsified approach.

● Cutting and Forging

Cutting the materials into the necessary lengths and widths comes next after the material has been chosen. The next stage is to slightly heat each component to a specific degree in order to forge them.● Trimming

Trimming comes next. Here, extra material or burrs are eliminated. To form the body into the proper valve shape, flashing is the next step.● Sandblasting

The next phase is sandblasting. The valve becomes clean and smooth as a result. The norms or requirements of the customer determine the size of the sand utilized. To start, the valves are sorted out in order to remove the faulty ones.● Machining

Depending on the design and needs of the client, machining further refines the sizes and forms of threads, holes, and the like.● Surface Treatment

The valve's surface is treated with specific acids and similar substances.5. Assembly

The process of assembly involves technicians joining all the valve parts together. The assembly is frequently carried out by hand. At this point, technicians designate the valves based on the regulations they adhere to, such as DIN or API, and so on, as well as their production numbers.6. Pressure Test

The valves must be put through real pressure testing to check for leaks during the pressure test phase. Occasionally, the closed valve is filled for a predetermined number of hours with air that has a pressure of 6–8 bar. Depending upon the valve size, it could take anything from two hours to a day.After the time period, valve repair takes place if there is a leak. If not, the valve will advance to the following stage.

In other situations, water pressure is used to find leaks. The valve passes the test if it doesn't leak while the water volume rises. This indicates that the valve is resilient to the rising pressure. The valve returns to the warehouse if there is any leakage. Before putting this batch of valves through another round of pressure tests, the specialists will inspect them for leaks.

7. Inspection and Quality Control

QA staff will now carefully check the valves for leaks and other production faults.

Conclusion

The process of making industrial valves is a complicated one. It is more than just the valve's basic creation. Its efficiency is a result of numerous elements, including the acquisition of raw materials, machining, heat treatment, welding, and assembly. Before manufacturers provide valves to customers, they should go through a series of rigorous tests to make sure they are operating properly.What distinguishes a high-quality valve, one would wonder? The test of time is one of the defining characteristics of high-quality valves. Long service life indicates high quality in valves.

Conversely, if the valve exhibits internal leakage, it is likely that the manufacturing techniques used do not meet the necessary criteria. Better valves typically have a five-year lifespan, but inferior valves usually have a three-year lifespan.

Next: What is Angle Type Globe Valve

Previous: What is Dome Valve and its principle