This blog post will describe the appearance and operation of a three-way ball valve. The several kinds of 3-way valves and their uses will also be covered.

What Is a 3-Way Ball Valve?

One kind of valve used to regulate fluid flow is the three-way ball valve. The gadget is basic, consisting of a ball with three ports. The ports line up with the ports on the valve body when the ball is turned. In doing so, the fluid is able to pass through the valve and into the proper outlet.

The three-way ball valve is an extremely simple and user-friendly piece of machinery. To get the ball to move into the proper position, simply turn the valve's knob. In addition, the three-way ball valve requires less upkeep and is easy to maintain. There are numerous applications for it. It can be used, for instance, to regulate the flow of water in a plumbing system or the airflow in an HVAC system. The three-way ball valve regulates the flow of liquids, like milk or juice, in the food and beverage sector.

Types Of Three-Way Valves

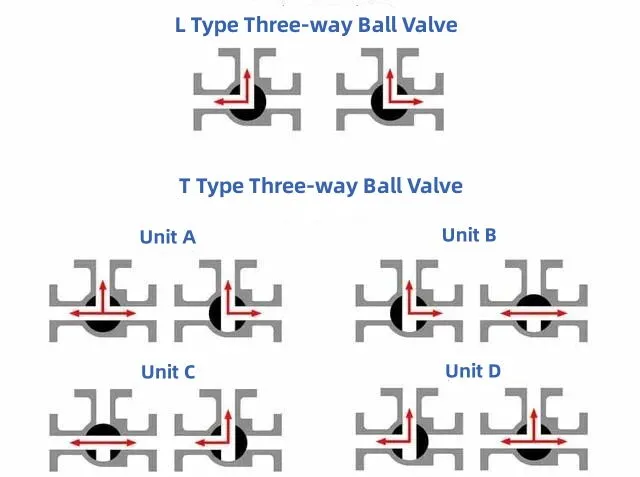

There are two patterns for three-way ball valves: the L-pattern and the T-pattern. The ball configuration is different, but the operating principle remains the same.

- L-Pattern Three-Way Valves

Several industries, including the production of cosmetics and the processing of food and beverages, use L-pattern three-way valves. These valves can be used to permit flow from one outlet to either of two outlets, or from two separate inlets to one outlet. When it's required to redirect flow to a different location or modify its direction, L-pattern three-way valves are frequently utilized.

- T-Pattern Three-Way Valves

A specialty valve utilized in a variety of industries, including manufacturing and food and beverage processing, is the T-Pattern 3-way valve. This valve's design permits two distinct fluids to flow in opposite directions while preventing their mixing. Because of this, it is the best option for applications requiring the independent management of two different fluids.

Advantages Of The 3 Way Ball Valve

Numerous industries employ the 3-way ball valve as one of their valve types. This valve is intended to regulate how gases and liquids pass through a pipe. The three-way ball valve has the following five benefits:

- The two-way flow of gases and liquids can be controlled using the 3-way ball valve.

- This kind of valve can be utilized in high-pressure situations and is quite dependable.

- The 3-way ball valve requires little maintenance and is simple to use.

- This kind of valve is adaptable and has a wide range of uses.

- The 3-way ball valve is a great choice for most sectors and is reasonably priced.

Disadvantages Of The 3 Way Ball Valve

- Size restrictions: The range of sizes in which 3-way ball valves can be purchased is somewhat small. It can be difficult to determine which size is appropriate for a certain application.

- Restricted flow: Because of the way they are made, 3-way ball valves have a set flow rate. If the applications require a high flow rate, this could be a problem.

- Restricted pressure: The maximum pressure that 3-way ball valves can withstand. This implies that high-pressure applications might not be a good fit for them.

- Intricate design: If a 3-way ball valve breaks, it might be challenging to fix because of its intricate design. If you need to quickly fix the valve, this could be an issue.

- Intimidating to install: Installing 3-way ball valves can be challenging, particularly for those who lack experience with the procedure. (Read more about installing ball valves here)

Three-Way Ball Valve Operation

The operation of each type of 3-way ball valve will be covered in this section. These operate somewhat differently from how a typical ball valve does. The handle or actuator of the L-pattern type, also known as a diverter valve, can be turned 90 degrees to shift the flow.

Assume that the left port is open and the top position has the lowest port. The valve rotates a quarter of a turn in a clockwise manner to guide media flow to the appropriate port. The media flow is stopped by another quarter bend in the opposite order. A 270-degree turn would stop the media's progress. Turning the valve 360 degrees will return it to its starting position. It is possible for two of the three ports to open at once. The ball valve can have two shutdown operations and three flow options thanks to this mechanism.

The mixer valve is another name for the T-pattern valve since it can integrate the media from both channel flows. After that, the media leaves from the other end. It is possible to concurrently unlock every port provided.

Because the T-pattern ball-valve functions similarly to the L-pattern, it can also be utilized as a diverter. A quarter turn of the handle will accomplish these. Although the T-pattern can only limit the discharge to two ports or allow access to all three, it is unable to provide a bubble-tight shutdown.

You can use the T-pattern ball valve as a mixer to let media flow in two different directions. Like a two-way valve, the T-pattern can split or permit straight flow patterns. A T-pattern vertically positioned ball valve's standard port is always open. It can be turned a quarter turn to deflect the flow. A 180-degree turn will not impact the media flow.

There are locking handles that can be turned to enable the valves to move. On the other hand, the 3-way valve's locks are 360 degrees rotatable. To make sense of the numerous ports, this is done. Usually, the bottom of the valve is where it is most commonly accessed.

3-Way Ball Valve vs. 2-Way Ball Valve.

A valve that can regulate fluid flow is a must in every system that handles fluids. Although there are many different kinds of valves that can be used for this, 3-way ball valves and 2-way ball valves are the most widely employed.

What distinguishes these two varieties of valves from one another, then? A 2-way ball valve only has two ports; a 3-way ball valve has three. In other words, a 2-way valve can only control fluid flow in two directions, whereas a 3-way valve can control it in three.

Usually, 3-way ball valves are utilized when it's necessary to regulate fluid flow in several directions. For instance, a 3-way valve is the best choice if a valve is required to regulate the water flow to a sprinkler system in order to turn the water on and off in multiple directions.

Conversely, 2-way ball valves are generally reserved for situations in which two-way fluid flow control is required. For instance, a 2-way valve works best to switch on and off the water while controlling the flow of water to a sink.

Conclusion

To sum up, a three-way ball valve regulates the flow of fluids. It is made up of a ball with three ports; two of the ports are attached to the valve's intake and outlet, and the third port is attached to a drain. The drain is used to flush the valve, and the ball is rotated to line the ports with the intake and output. See our blog entry on how a ball valve works to find out more about the various ball valve functions. To buy a dependable 3-way ball valve for various industrial applications, get in touch with the top producers of industrial valves.