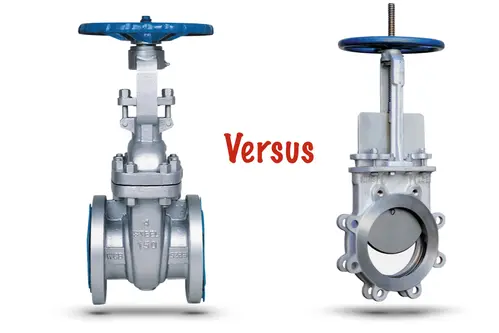

While gate valves and knife gate valves share many similar characteristics, there are some fundamental differences that set them apart.

While knife gate valves and gate valves share many similarities – they’re both used in on-off applications, involving slurries and other viscous media – there are some noteworthy design variances to consider when weighing up which type of valve would be best suited for your application.

Gate valves open by lifting a round or rectangular gate (or wedge) out of the path of the fluid. The sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is needed. They have a flat gate closure that slides in and out or up and down between two parallel plates to open or close the valve. Gate valves are used for shut-off, rather than flow regulation because they only have two settings: on and off.

While a knife gate valve performs exactly as the name implies. These types of valve were originally designed for the pulp and paper industry. Stringy pulp would impinge between the wedge and seat of a normal gate valve and prevent flow shut-off. Knife gate valves were designed with a sharp edge to cut through the pulp and seal. With this type of useful attribute, the knife gate valve has become invaluable in applications involving slurry, viscous fluids and other systems where impingement is an issue.

Gate valves are used in many industrial applications requiring shut-off valves, including the oil and gas industry, pharmaceuticals, manufacturing and automotive. They can cope in demanding environments, such as high temperature and high pressure environments. Common gate valve applications include in power plants, water treatments, mining and offshore applications.

Knife gate valves are advantageous in sludge and slurry applications because their blades cut right through thick liquids easily. They’re generally specified in larger sizes for handling thick flows of heavy oils, light grease, slurry, paper pulp, varnish and wastewater to name but a few knife gate valve applications.

One of the advantages of gate valves is that pressure drop across a gate valve is very low when it is fully open. They can also be used for bi-directional action and are useful as on-off valves. Gate valves do, however, need a large force to operate and large sized valves need automatic actuators. They’re not quick to open or close, and take up more space, when compared to some other valves. Thermal expansion and shrinking can also lead to unwanted leakage in some gate valves that are exposed to high temperature fluctuations.

The advantages of knife gate valves are that they’re cheap, easy to actuate, and light. One of the most notable disadvantages of knife gate valves is that they’re known to have low-pressure limitations. This makes them less desirable for use in applications that require cleanliness or sanitary conditions.

Next: HOW DOES A KNIFE GATE VALVE WORK

Previous: Stellite 6 Coating for Valves