Continue reading to discover the distinctions and how to choose the best one for your needs.

What is A Gate Valve?

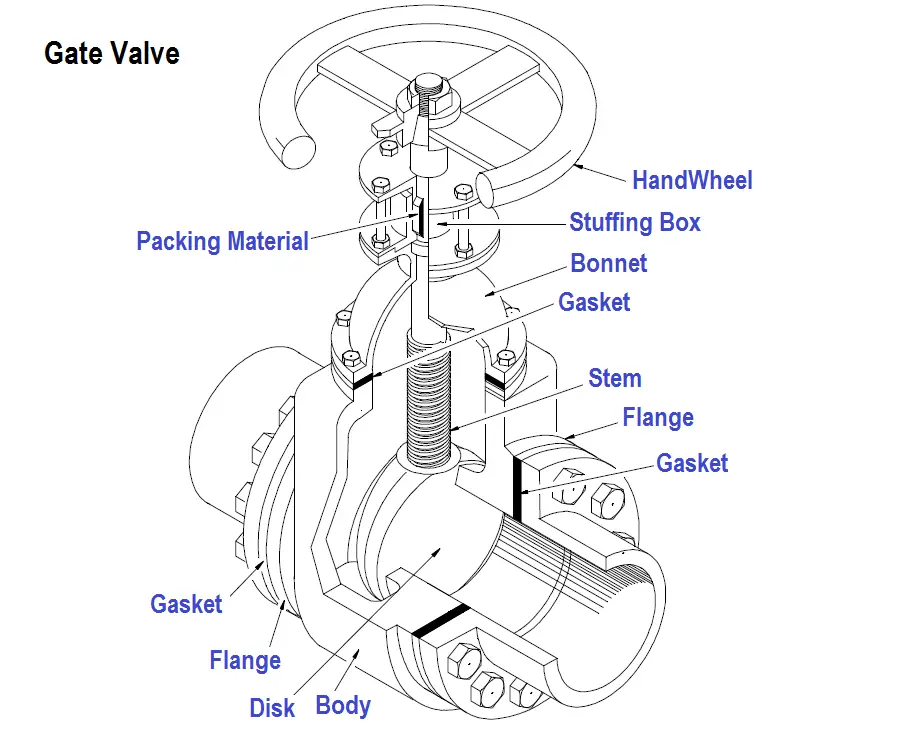

With gate valves, the flow of fluid through a pipeline can be fully stopped or resumed by raising or lowering a solid, rectangular gate. The valve body, seat, disc, spindle, gland, and actuator make up these valves.

Gate valves are meant to be fully open or fully closed; flow is not controlled by them. These valves take more than a 360° turn to change the gate's position, whereas a ball valve only has to turn 90° to cycle from open to closed or vice versa. This makes these valves slower than quarter-turn valves, such as ball valves. For applications that demand quick cycle durations or frequent operation, gate valves might not be the ideal option. Although electronic and pneumatic actuation alternatives are also available, a manual handwheel is the most typical method of controlling gate valves.

What is A Ball Valve?

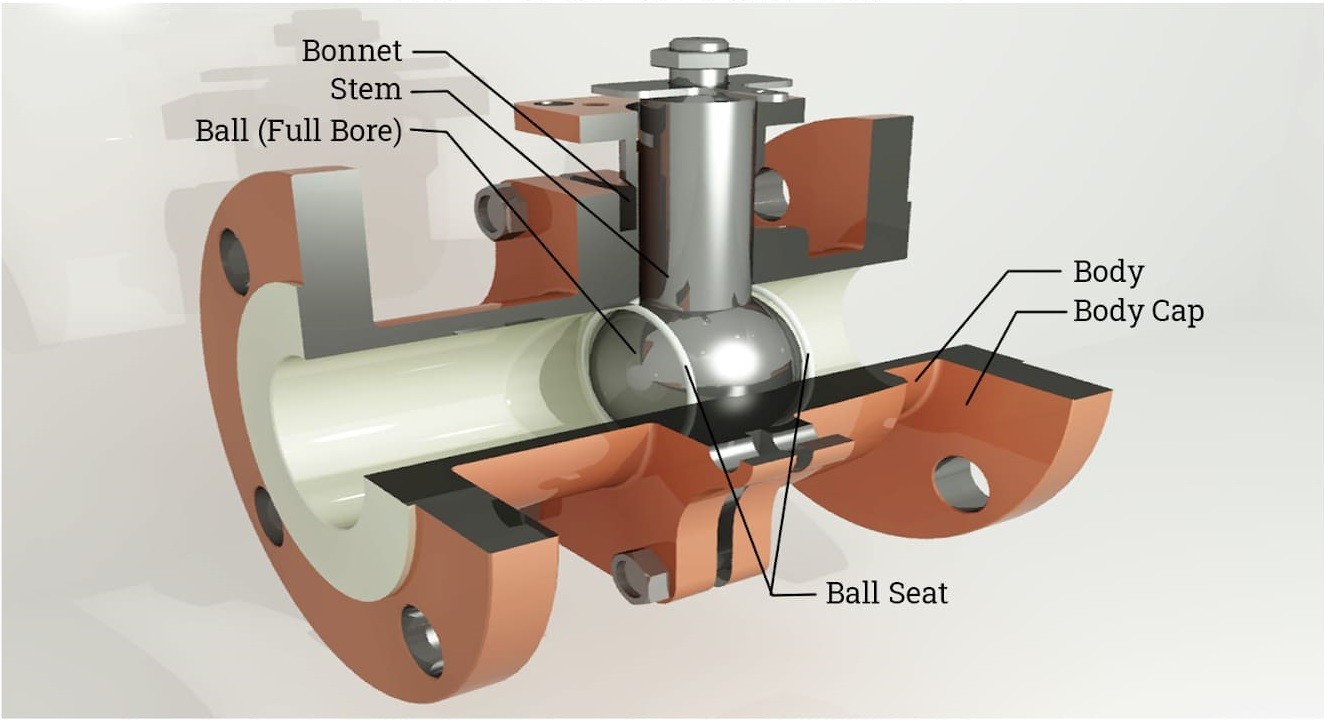

A ball valve uses a movable ball to regulate the flow of liquid or gas, whereas a solid rectangular gate controls the flow of media through a gate valve. The media goes through a bore (or hole) in the ball, and the position of the media shows whether the valve is open or closed.

Ball valves can be made with several ports, or apertures, in its design. Two-way ball valves are used for simple on/off control and have two ports. Multi-port valves are also available and are utilized in applications where multiple media sources or directions for media diversion are needed.

Ball valves are a quicker option for on/off control than gate valves since they simply need to be turned 90° to control the position of the ball. Ball valves can be operated manually or automatically.

As we previously discussed, gate valves are controlled by raising or lowering a gate, whereas ball valves work by rotating a ball ninety degrees. Ball valves have a nearly instantaneous shutoff capability due to their design, something that gate valves cannot match. Because of this, ball valves are a preferable option in applications that require a high cycle speed.

As we previously discussed, gate valves are controlled by raising or lowering a gate, whereas ball valves work by rotating a ball ninety degrees. Ball valves have a nearly instantaneous shutoff capability due to their design, something that gate valves cannot match. Because of this, ball valves are a preferable option in applications that require a high cycle speed.Ball valves operate at a 90° angle, which accelerates their cycle time when operated manually or by an actuator. This is generally advantageous, but in high-pressure applications, it may result in water hammer. Turning the levers slowly prevents water hammer in manual ball valves, which can weaken or even break the pipe if the pressure builds up enough.

| Gate Valve Uses | Ball Valve Uses |

| Shutoff and isolation service for:

A common sight in older residential plumbing systems is the gate valve. |

On/off control for specialized industries including:

The plumbing systems in more recent homes also contain ball valves. |

Cost

Cost is a key differentiator in the gate vs. ball valve debate. Although gate valves are initially less expensive than ball valves, they will require more maintenance and replacement because of their increased susceptibility to corrosion. Ball valves are more expensive initially, but because of their superior durability and ability to create tight seals, they are the longer-lasting option.

As we just covered, ball valves typically have greater durability than gate valves. Gate valves will need to be replaced or maintained on a regular basis in applications with moderate or high cycle. Ball valves should be replaced rather than repaired because they are primarily made to require little maintenance. On the other hand, three-piece ball valves are made to make it simple to replace the seals and valve seats without taking the valve out of commission. Because valve seal failure is likely to happen more quickly in high cycle or high pressure applications, three-piece ball valves are frequently used in these situations. Generally speaking, 3-piece ball valves are more expensive initially than the more common 1- or 2-piece body constructions.

Is It Better to Use a Ball Valve or a Gate Valve?

In the end, the application will determine whether to use a ball valve or a gate valve. Applications requiring minimal installation space and infrequent operation are best suited for gate valves. Applications requiring quick cycle times, numerous ports, dependable, tight seals, and/or frequent operation are best suited for ball valves.

To help you make your decision even more, here is a summary of the topics we covered in this article:

Type of Media

Ball valves are suitable for use with both liquids and gases because they produce a dependable, tight seal. Because gate valves leak more often, they are better suited for thick liquids like oil.

Space

Ball valves need more room to operate even though they are smaller than gate valves. A manual gate valve can be operated with a small handwheel, but a manual ball valve needs a lever that can turn 90 degrees. Small form factor handle options, like wing or round-style handles, are available for certain ball valves. Larger ball valves frequently lack sufficient leverage for these handles, despite the fact that they function well with smaller pipe sizes.

Application

For liquid media applications that need infrequent operation, gate valves are advised. Many industries that need to actively and quickly control the flow of media use ball valves.

Ports

Gate valves are not as commonly available in multi-port configurations as ball valves. A ball valve can be the best option if the flow pattern required by your application is multi-port.

Contact JONLOO here to learn more or to speak with a specialist if you're unsure whether a ball valve or gate valve is best for your application.