As both globe and gate valves are made by valve manufacturers to maintain systems operating as safely and efficiently as possible, they rank among the most often used valves in industrial facilities. Their distinct designs serve mainly to support their own applications.

Globe Valves :

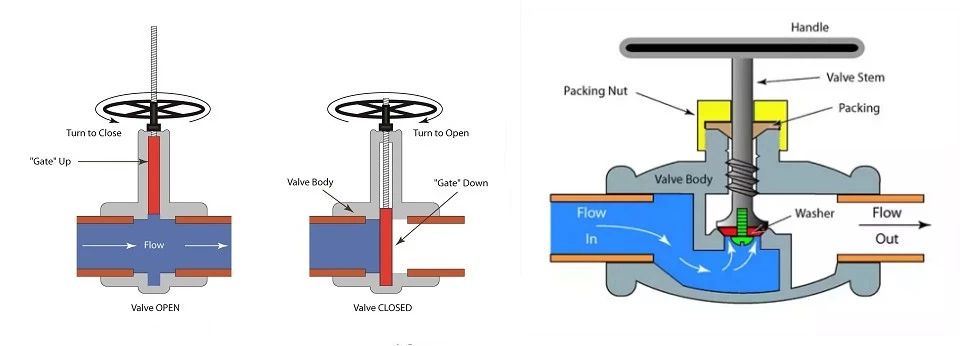

The linear motion valve family, which includes the Globe valves, is made for a variety of industrial uses, including the oil and gas sector. These valves use linear motion to control the throttle flow, much like gate valves. Its duties include controlling the media's start and stop as well as the pipe's flow. Because of their construction, which consists of a disc and a spherical body, they offer maximum leakage stopping and a tighter seal.

These valves are frequently preferred by Globe Valve Supplier because they are ideal for applications where leaks and safety are the primary concerns. The fact that a globe valve leaks less frequently than other valves is a superior benefit. The globe valve's vertical disc movement is especially made to give these valves excellent throttling capabilities, enabling them to control pipeline flow. These valves are frequently used in systems with higher pressure and temperature, highly viscous media, and corrosive media because they can also be used as control valves.

Gate Valves :

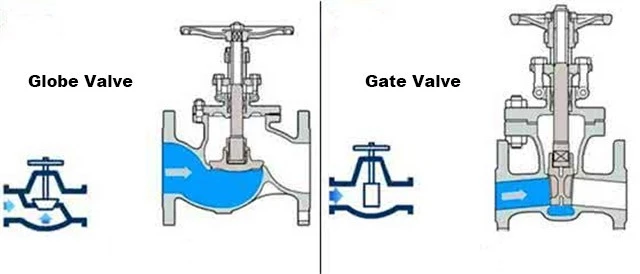

In most situations, gate valves are made with parallel or wedge-shaped discs for the gate faces and either a rising or non-rising stem. The basic mechanism involves the gate disc moving upward to open the valve, which results in minimal pressure drops because the media flow is unhindered. Additionally, it closes by lowering the disc to meet the seats. These valves, particularly when fully open, provide minimal obstruction to fluid flow and are renowned for having lower pressure drops. Above all, because gate valves can be adjusted for any direction of flow, the Gate Valves Supplier highly recommends them to clients in a variety of industries.

Their Structural Design :

• The cavity itself contains the globe valve components. The structural design of the valve permits obstructions that facilitate the valve's primary function of positive shut-off and throttle. The globe's rising stem allows for variations in flow rate and direction, which in turn contribute to the high-pressure drop phenomenon.

• Because the majority of a gate valve's internal components are located on the top of the valve body, gate valve construction is significantly simpler. Their stem may be non-rising or rising. When it is turned on, the body becomes hollow, which causes a slight pressure drop.

Their Functions :

• The globe valve is primarily more of a control valve.

• The gate valve is designed for the media isolation not for the flow control.

Their Applications

• The globe valve is unidirectional and best used in applications where massive changes in pressure are not an issue.

• The gate valve is a multidirectional valve specifically suitable for applications where low-pressure drops are of utmost importance.

Their Working :

The disc lodges between the seats in the gate valve's operating mechanism. It moves in a manner that is correctly angled with respect to the media flow. It offers complete flow or none at all. As you can see in the first image, when the valve is opened, the flow space is the same as the valve cavity plus a small amount more where the seats and stem are situated.

In contrast, the globe valve disc travels in a direction perpendicular to the media flow. The disc only needs to move slightly from the seat when it is in a full flow. Throttling and tight shutoff are made possible by its design, as seen in the second image above.

Conclusion:

One interesting aspect of valves is that, despite having a similar appearance, they can have very different functions. This still holds true for globe and gate valves. If you are seeking an industrial valve supplier, you can choose JONLOO valve company.