Comprehending the many kinds of bypass valves and their applications

What is a bypass valve?

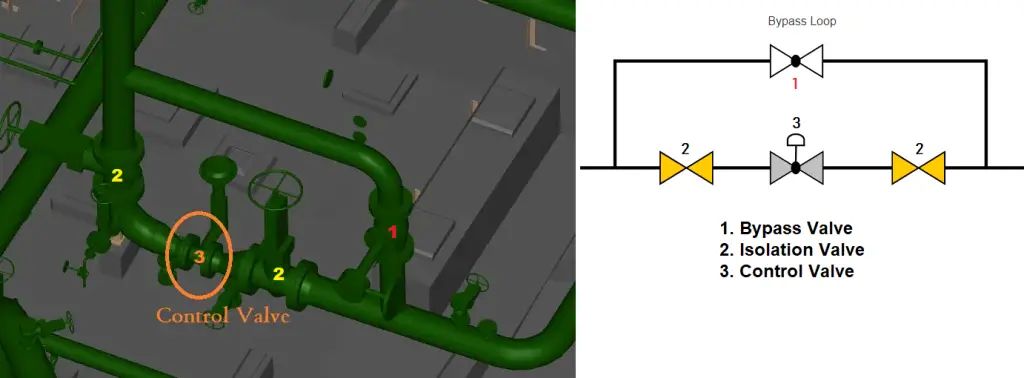

Bypass valves are a type of valve used in oil and gas piping applications to reroute or divert fluid flow within a system. By establishing a different flow path, it enables the fluid to avoid specific parts or segments of the pipe system. Bypass loops or bypass lines are used to mount bypass valves. A bypass valve's key functions are system safety, maintenance ease, and operational flexibility. Bypass valves are frequently used in oil and gas pipes.

What function does a hydraulic system's bypass valve serve?

- Pressure Regulation: By rerouting fluid away from certain components when the pressure reaches a predetermined threshold, bypass valves aid in controlling system pressure. By doing this, possible harm from too much pressure is avoided.

- Flow Control: When required, they divert the hydraulic fluid to maintain a steady flow. This is especially helpful in systems where it's essential to maintain a certain flow rate.

- Protection: Bypass valves guard against pressure spikes and blockages that could harm delicate hydraulic system parts like pumps and actuators. They aid in preventing system failures by permitting fluid to avoid the impacted area.

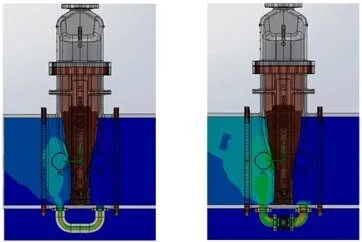

- Cooling: By letting fluid flow through a cooler rather than through high-load zones, bypass valves can assist control heat in some hydraulic systems and lower the chance of overheating.

- System Maintenance: Bypass valves can separate specific system components during maintenance or troubleshooting, enabling repairs or inspections without completely stopping the hydraulic system.

What varieties of bypass valves are available?

Below is a summary of the various kinds of bypass valves that are available:

- Pressure Relief Valves - These valves allow fluid to avoid vital components by opening when the system pressure rises above a certain threshold.

- Solenoid Valves - These electromagnetic solenoid-operated valves are capable of automatically opening or closing in response to electrical impulses.

- Manual Valves - To open or close these valves, one must manually operate them. Usually, the operator controls a lever or knob on them.

- Spring Loaded Valves - These spring-operated valves automatically open or close in response to variations in system pressure.

- Float Valves - When the liquid level reaches a certain point, these valves can bypass because they open and close using a floating mechanism.

- Check Valves - When necessary, these valves efficiently avoid certain parts of the system by permitting forward flow while blocking backflow.

- Variable Valves - Operators can alter the system's performance according to particular needs thanks to these valves' changeable bypass flow rates.

- Flow Control Valves -Bypass capabilities and flow control elements are combined in these valves to precisely regulate fluid flow while avoiding specific areas.

How do you figure out a bypass valve's proper dimensions and specifications?

For hydraulic or fluid systems to operate at their best, choosing the right bypass valve size and specifications is essential.

1. Understand the Application Requirements

Fluid Type: Determine the kind of fluid (oil, water, etc.) and its characteristics (temperature, corrosiveness, viscosity).

Operating Conditions: Take into account the valve's operating temperature, pressure, and flow.

2. Calculate the Required Flow Rate

Flow Demand: Find the highest flow rate that the system needs to function normally. Typically, this is stated in liters per minute (LPM) or gallons per minute (GPM).

Bypass Flow Rate: Indicate the flow rate that must be avoided when the valve is opened, if any.

3. Determine the Pressure Requirements

System Pressure: Determine the hydraulic system's maximum operating pressure. This will assist in choosing a valve that can reliably withstand the necessary pressure.

Pressure Drop: Since this will impact system efficiency, figure out the anticipated pressure drop across the valve at the intended flow rate.

4. Choose the Valve Type

Based on the requirements of the system, choose the right kind of bypass valve (e.g., manual, solenoid-operated, pressure relief, etc.).

Think about things like control strategies, automation requirements, and whether a manual override is necessary.

What distinguishes pressure relief valves from bypass valves?

Despite their apparent similarities, bypass valves and pressure relief valves have different purposes in hydraulic and fluid systems. The following are the main distinctions between the two:

- A bypass valve's main purpose is to reroute flow around a specific part or area of the system. This is helpful in situations where constant flow is required while permitting some fluid to avoid a particular region (like a filter or heat exchanger) while it is not in use or requires maintenance.

- A bypass valve usually responds to flow demand. Depending on the system architecture, it can be operated manually or automatically.

Is it possible to incorporate bypass valves with other parts like pressure relief or flow control valves?

It is true that bypass valves can be combined with other parts of hydraulic systems, such as pressure relief and flow control valves.

What symptoms indicate that a bypass valve is not working properly?

In a hydraulic system, a broken bypass valve can cause a number of problems. The following indicators suggest that a bypass valve might not be functioning properly:

- Unusual Pressure Fluctuations

- Overheating

- Reduced Flow Rate

- Fluid Leaks

- Inconsistent Actuator Performance

- Noisy Operation

- Warning Indicators on Control Panels

- Contamination in Hydraulic Fluid

- Slow or Inhibited Response Times

- Bypass Valve Sticking