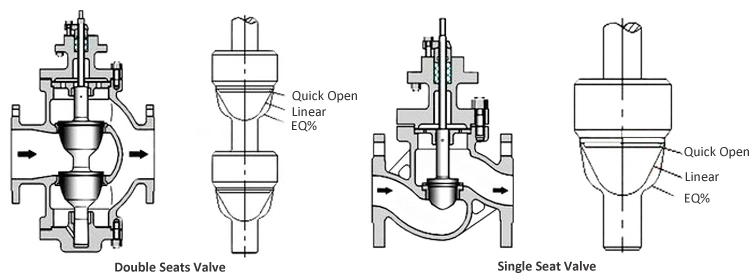

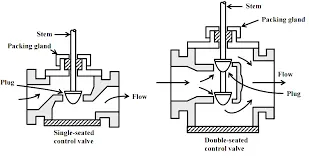

The advantage of the double-seat of valve is the balance structure of force and the big allowable pressure difference, but its outstanding disadvantage is that the two sealing surfaces cannot be in good contact at the same time, resulting in large leakage. If it is artificially or forcibly used for cuting off, the effect is obviously not good, even if many improvements (such as double-sealed sleeve valves) have been made for it, it is not advisable.

2. Why is the double-seated control valve easy to vibrate when works with a small opening?

For a single core, when the medium is a flow-open type, the valve stability is good; when the medium is a flow-close type, the valve stability is poor. The double-seat valve has two cores, the lower of which is closed and the upper is open. In this way, when working at a small opening, the flow-closed core will easily cause the valve to vibrate. That is the reason why the double-seat valve cannot be used for small opening work.

3. Why the liner control valve has poor anti-blocking performance, but rotary control valve has good anti-blocking performance?

The core of the liner control valve throttles vertically, while the medium flows in and out horizontally. The flow path in the valve chamber must turn and turn backwards, making the flow path of the valve quite complicated (the shape is like an inverted S shape). In this way, there are many dead zones, which provide space for the precipitation of the medium, and if things go on like this, it will cause blockage. The throttling direction of the rotary control valve is the horizontal direction. The medium flows in horizontally and flows out horizontally. It is easy to take away the dirty medium. At the same time, the flow path is simple and there is little space for the medium to settle, so the rotary control valve has good anti-blocking performance.

4. Why is the cut-off pressure difference of the rotary motion control valve larger?

The rotary motion control valves have a large cut-off pressure difference because the resultant force generated by the medium on the valve core or valve plate produces a very small moment on the rotating shaft, so it can withstand a large pressure difference.

5. Why is the valve stem of the liner control valve thin?

It involves a simple mechanical principle: large sliding friction and small rolling friction. The stem of liner control valve moves up and down. If the stuffing slightly pressed tighter, it would wrap up the stem tightly, resulting in a large hysteresis. To this end, the valve stem is designed to be thin and small. The PTFE stuffing has a small friction coefficient in order to reduce the hysteresis. But the problem that derives from this is that a thin valve stem is easy to bend and the stuffing has a short service life. To solve this problem, the best way is to use rotary valve stem, similar to the rotary stroke ones. Its valve stem is 2 to 3 times thicker than that of the liner control valve, and the graphite packing with long service life is used to improve the stiffness of the valve stem. Well, the packing has a long service life, but its friction torque is small and the hysteresis is small.

6. Why do rubber-lined butterfly valves and fluorine-lined diaphragm valves have short service life for desalinated water?

The desalinated water medium contains a low concentration of acid or alkali, which are highly corrosive to rubber. Corrosion of rubber is manifested as expansion, aging, and low strength. The rubber lined Butterfly valves and diaphragm valves are poor in use. The essence is that the rubber is not resistant to corrosion. The rubber-lined diaphragm valve was then improved to a fluorine-lined diaphragm valve with good corrosion resistance, but the diaphragm of the fluorine-lined diaphragm valve could not withstand folding up and down, then was broken, causing mechanical damage and shortening the life of the valve. The best way now is to use a special ball valve for water treatment, which can be used for 5-8 years.

7. Why should the shut-off valve be hard sealed as much as possible?

Shut-off valves require that the leakage be as low as possible. The leakage of soft-sealed valves is the smallest. Of course, the shut-off effect is good, but it is not wear-resistant and has poor reliability. Judging from the double standards of small leakage and reliable sealing, the soft seal of shut-off valve is not as good as hard seal. For example, the full-featured ultra-light control valve is sealed and protected by wear-resistant alloys, with high reliability and a leakage rate of 10-7, which can already meet the requirements of shut-off valves.